A multi-phase multi-coil induction heating device and method

An induction heating equipment, multi-coil technology, applied in induction heating, induction heating control and other directions, can solve the problems of low heat uniformity and efficiency, poor practicability, increase coil height, etc., to reduce human injury and interference, and uniform electromagnetic intensity. , reduce the effect of electromagnetic radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

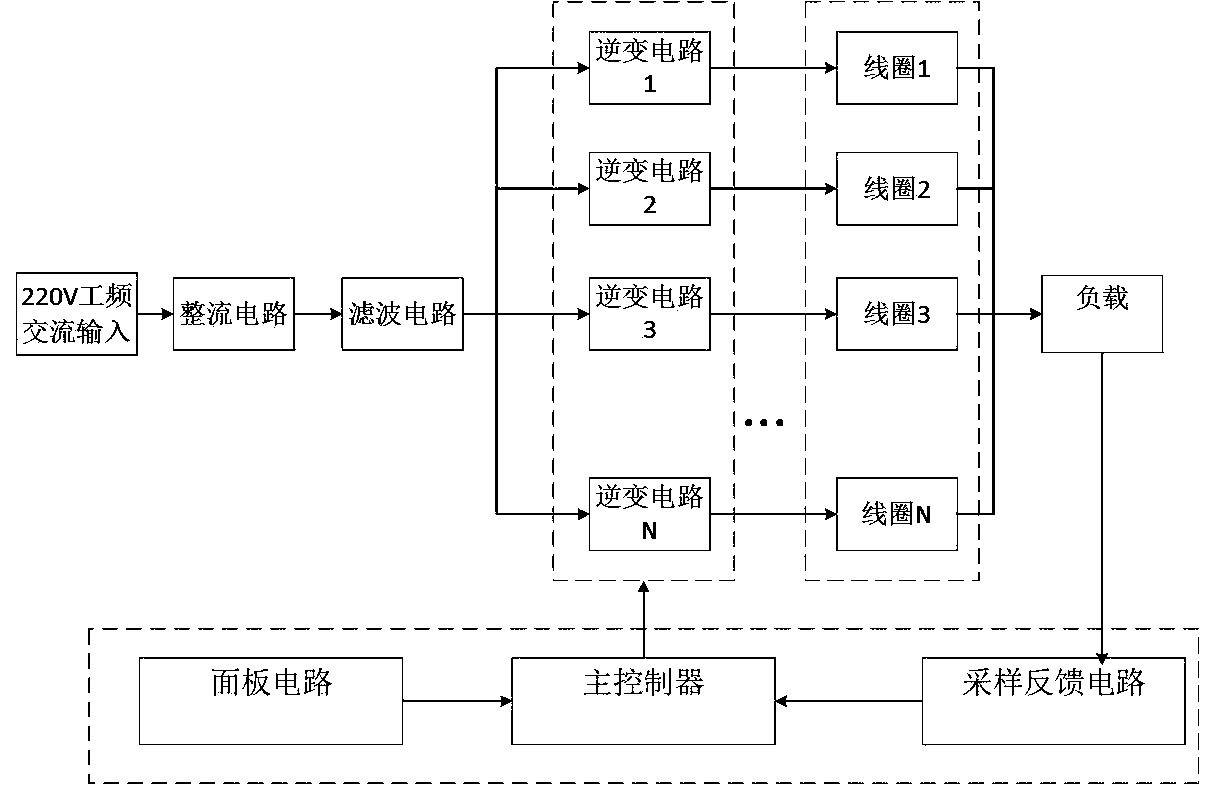

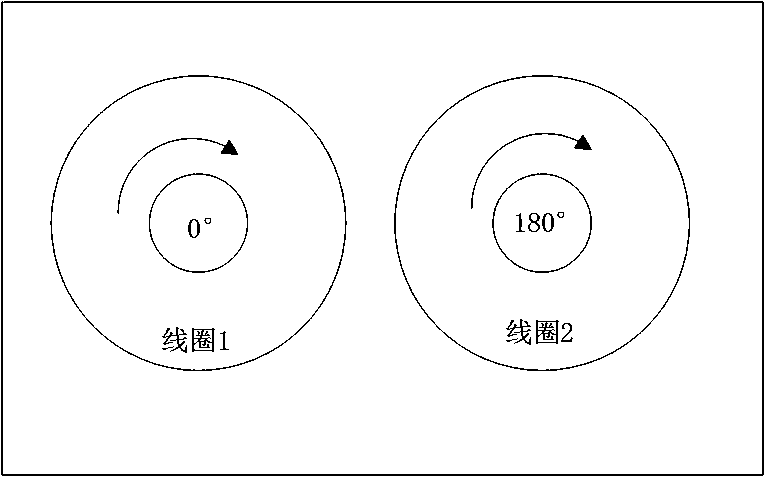

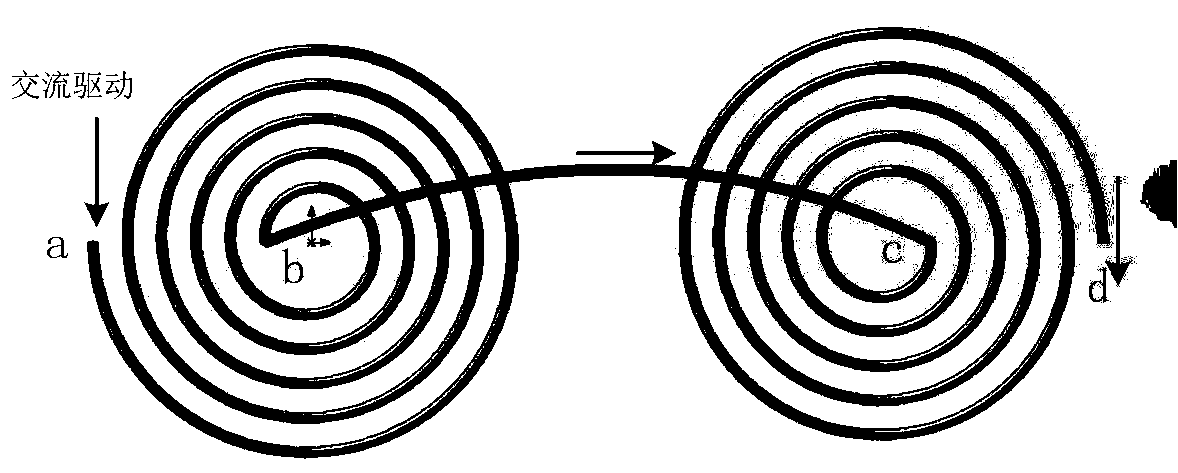

[0034] As shown in the figure, this embodiment provides a multi-phase multi-coil induction heating device, including a main circuit, a control circuit, N coils, and a magnetic core, wherein N is a positive integer greater than or equal to 2; the main circuit includes rectification circuit, filter circuit, N inverter circuits; the control circuit includes a main controller and a panel circuit connected thereto; the input end of the rectification circuit is connected to a 200V power frequency AC power supply, and the output end of the rectification circuit is passed through The filter circuit is connected to N inverter circuits, and the N inverter circuits are respectively connected to N coils, and a magnetic core is arranged under the coils.

[0035] In this embodiment, the rectification circuit is a bridge rectification circuit.

[0036] In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com