Catalyst for synthesizing carbon nanotube, containing amorphous alpha-alumina, and method for preparing carbon nanotube by using same

A carbon nanotube and catalyst technology, which is applied to a catalyst for synthesizing carbon nanotubes containing amorphous α-alumina and the preparation field of carbon nanotubes using the catalyst, and can solve problems such as CNT quality reduction and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

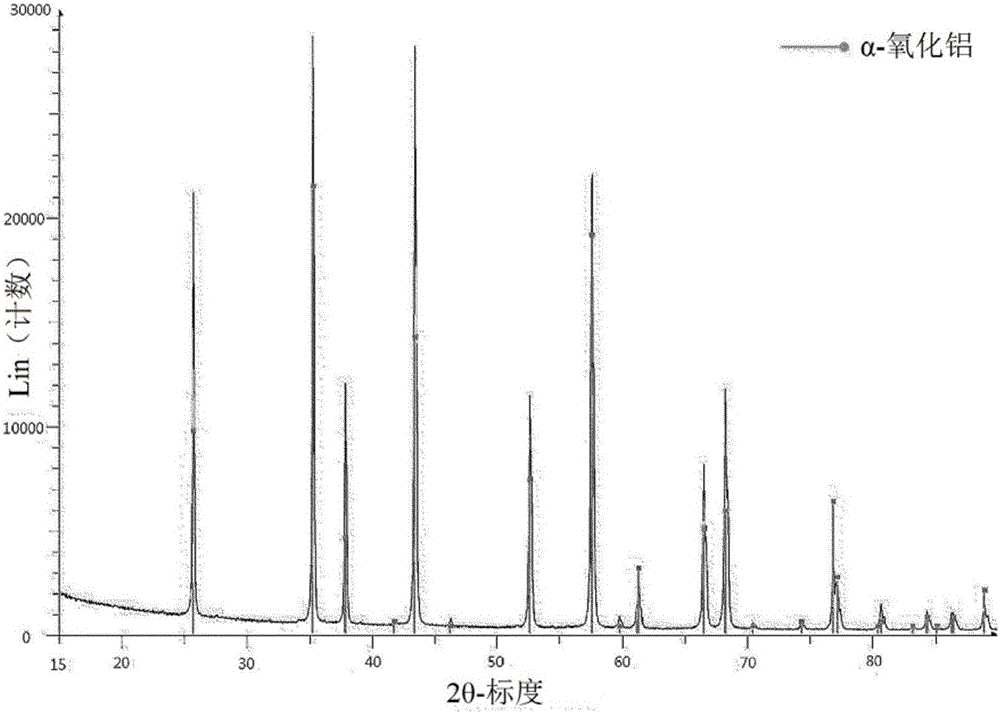

[0038] According to one embodiment, the amorphous α-alumina can be prepared by a method known in the art. For example, the method of producing alumina using bauxite is widely used in industry by the Bayer (Bayer) method. Similarly, spherical α-alumina can be obtained by adding γ-Al 2 o 3 Or any water-containing (hydrous) oxide is prepared by heating to a temperature greater than 1000°C.

[0039] The amorphous α-alumina used in the present invention may be formed in any appropriate size. For example, the amorphous α-alumina used in the present invention may have about 0.01 m 2 / g to about 1m 2 / g surface area, preferably, may have about 0.1m 2 / g to about 1m 2 / g surface area.

[0040] An alternate supported catalyst for carbon nanotubes according to one embodiment comprises a metal catalyst supported on the surface of the amorphous α-alumina, and these metal catalysts can support about 5 to about 40 parts by weight. In the range as described above, when CNTs are prepar...

Embodiment 1

[0059]

[0060] As a catalyst metal precursor, 2.39 g of Fe(NO 3 ) 2 9H 2 O, 7.34g of Co(NO 3 ) 2 ·6H 2 O, 0.55g of (NH 4 ) 6 Mo 7 o 24 and 0.34g of NH 4 VO 3 Completely dissolve flask A in 100 ml of distilled water. As a support, 12.5g of amorphous α-Al 2 o 3 (D50v=73μm, D50n=33μm, pore volume: 0.00035cm 3 / g, the surface area is 0.156m 2 Add the flask A in the flask B of / g, Saint Gobain company product), and the catalyst metal precursor is supported on the amorphous α-Al 2 o 3 After that, aging was performed by stirring for 1 hour in a constant temperature reactor including a 100° C. circulation tank.

[0061] After drying for 60 minutes in a 60° C. thermostat at 100 rpm and 40 mbar (mbar) in a rotary vacuum device, it was fired at a firing temperature of 720° C. for 4 hours to prepare a supported catalyst.

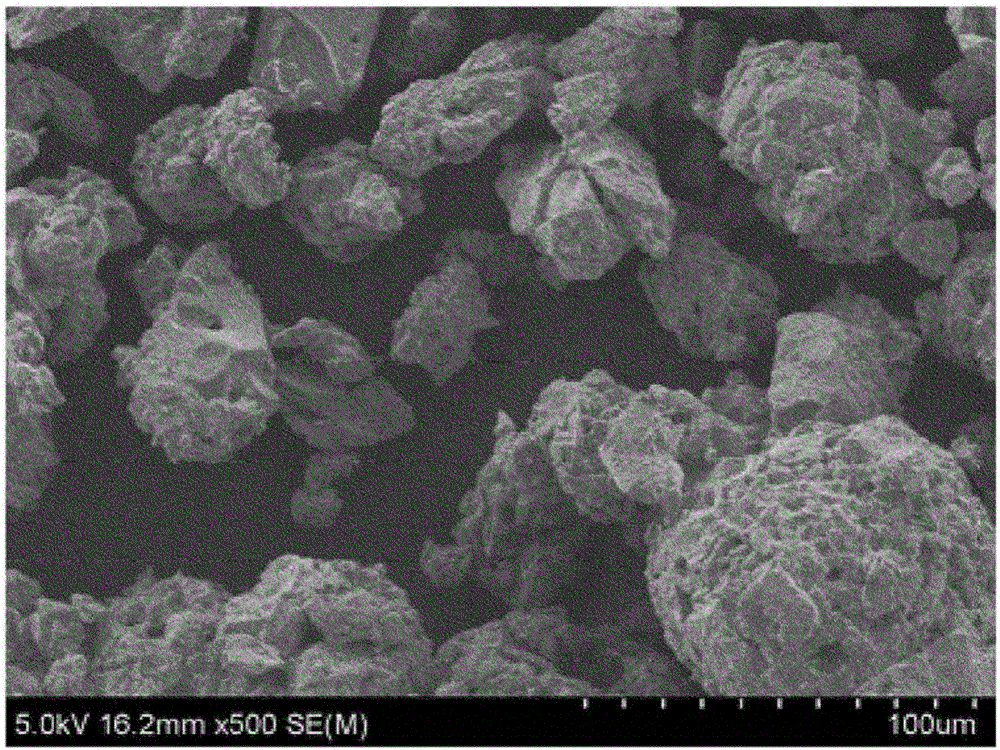

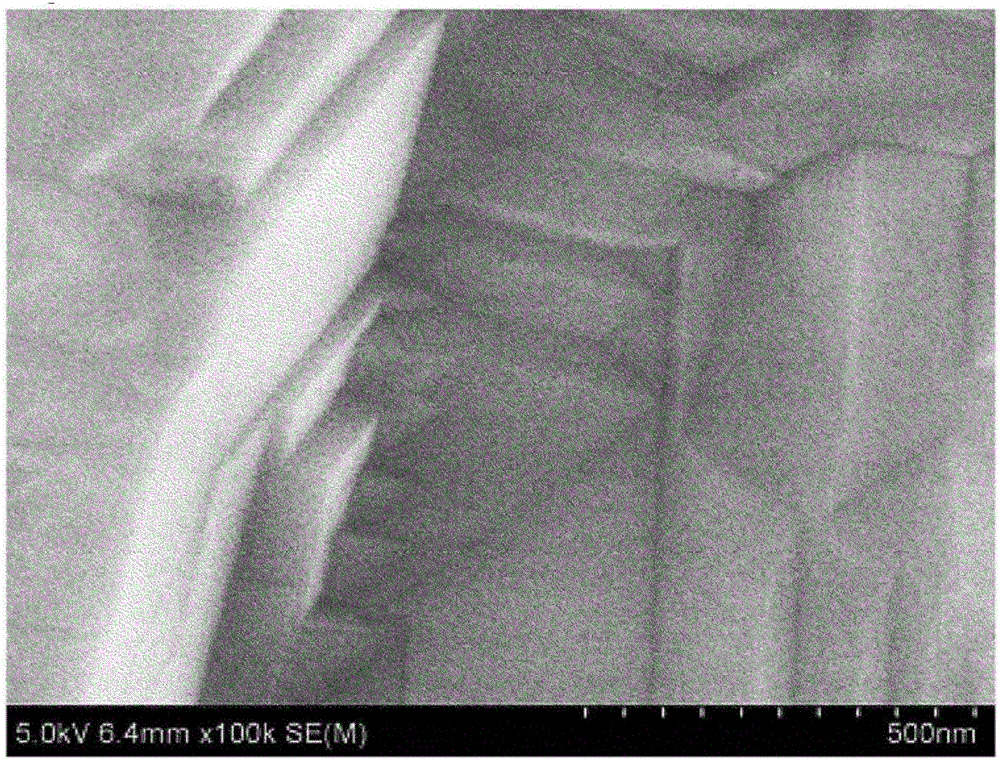

[0062] figure 1 showing a scanning electron microscope image of the amorphous α-alumina used as the support, figure 2 An enlarged view thereof is...

Embodiment 2-5

[0075] CNTs were prepared in the same manner as in Example 1 except that the catalyst firing temperature of 720°C was set to 625°C, 650°C, 680°C, and 700°C, respectively.

[0076] Figure 9 Scanning electron micrographs of the shapes of CNTs prepared by changing the catalyst firing temperature at the same magnification, Figure 10 is a graph showing the CNT yield.

[0077] Table 2 shows the length of CNT according to the catalyst firing temperature.

[0078] [Table 2]

[0079]

[0080]From the above results, it can be known that the higher the calcination temperature of the catalyst, the longer the length of the final CNT prepared. Therefore, it can be seen that the length of the final CNT prepared can be controlled by controlling the calcination temperature of the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com