High-strength cold-rolled steel sheet, high-strength hot-dip galvanized steel sheet, and high-strength hot-dip galvannealed steel sheet having excellent ductility, stretch-flangeability, and weldability

A technology of hot-dip galvanized steel sheet and cold-rolled steel sheet, applied in the field of high-strength cold-rolled steel sheet, can solve problems such as weldability research, and achieve the effects of excellent stretch flangeability and excellent weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0119] The following examples are listed to illustrate the present invention more specifically, but the present invention is not limited by the following examples, and can also be implemented by appropriately adding changes within the scope of meeting the aforementioned and hereinafter-described gist, and these are also included in this document. within the technical scope of the invention.

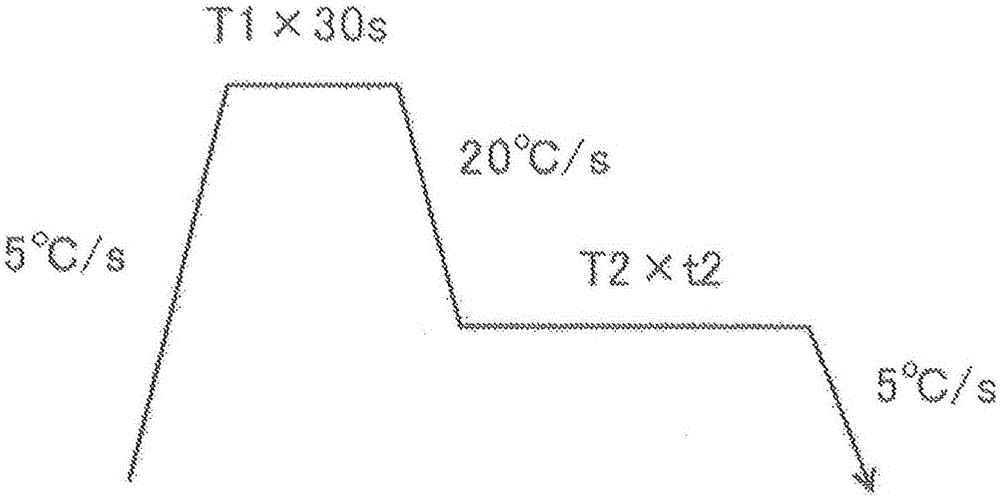

[0120] Steel ingots having the compositions shown in Table 1 below were subjected to vacuum melting. Then, it heated to 1250 degreeC, and implemented hot rolling to plate thickness 2.8mm. The finishing temperature was 900°C, the average cooling rate from hot rolling finish rolling to coiling was 20°C / s, and the coiling temperature CT was the temperature shown in Table 2 and Table 3 below. Next, the obtained hot-rolled steel sheet was pickled, and then cold-rolled to a plate thickness of 2.0 mm. Then, in figure 1, Table 2, and Table 3 under the conditions shown in the heat treatment. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com