Canister for containing an active agent

A technology of vacuum carburizing and manufacturing methods, which is applied in the field of carburizing parts, can solve the problems of insufficient improvement of surface softening properties, inability to obtain miniaturized surface fatigue strength and bending fatigue strength, and achieve excellent bending fatigue strength and surface Excellent effect on fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0094] Hereinafter, the present invention will be described more specifically with reference to examples. The present invention is not limited by the following examples, and within the range that can meet the above-mentioned and hereinafter-described purposes, of course, it can also be appropriately modified and implemented, and these are included in the technical scope of the present invention.

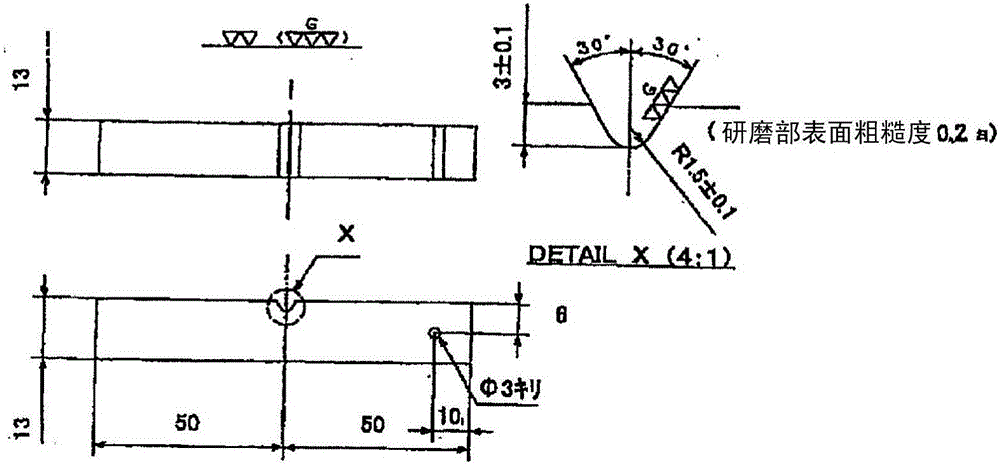

[0095] Steels having the chemical composition shown in Table 1 below were melted, held at 1250° C. for 30 minutes to 300 minutes, and then billet-rolled. The balance of the chemical composition shown in Table 1 is iron and unavoidable impurities. Thereafter, as shown in Tables 2 and 3, the pre-rolling heating temperature is 920° C. to 1100° C., and the heating retention time is 0.3 to 6 hours to perform hot rolling to obtain The hot-rolled material, that is, bar steel. Note that Steel No. 1 shown in Table 1 is a steel equivalent to the conventional steel SCr420H.

[0096] [Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending fatigue strength | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com