Tibetan chicken feeding trough

A technology for feeders and Tibetan chickens, applied in the field of feeders, can solve the problems of the influence of feeding and breeding conditions, the inability to achieve accurate quantitative, and the uneven feeding of food materials, so as to reduce the influence of human factors, accurately feed, reduce The effect of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

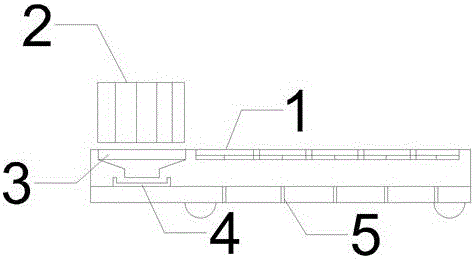

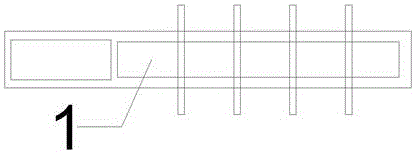

[0036] Such as Figure 1 to Figure 2 As shown, a Tibetan chicken feeder includes an isolated feeding area and a feeding area, and the feeding area includes several feeding troughs 1, and a spacer bar is arranged between the two feeding troughs 1. Below the feeding troughs 1 A conveying device is provided, the conveying device runs through the feeding area, and the conveying device communicates with the feeding area and the feeding area. The feeding area includes a grinding mechanism 3, a food storage area 2 is arranged above the grinding mechanism 3, and a feeding tray 4 is arranged below the grinding mechanism 3, and the feeding tray 4 is placed on a conveying device, and is transported to the feeding area by the conveying device. Area. The bottom of the feeding trough 1 is provided with a telescopic baffle, the bottom of the feeding trough 1 has a certain distance from the conveying device, and the upper surface of the feeding trough 1 is also provided with a baffle; the su...

Embodiment 2

[0038]A Tibetan chicken feeder, the feeding process includes the following steps

[0039] Step 1, input the feeding ratio setting value, the feeding weight k of each feeding trough and the number n of feeding troughs into the central processing unit, and the central processing unit calculates the weighing value of different food materials according to the feeding ratio, k and n, The central processing unit controls the opening and closing of the opening and closing device, and compares the weight reduced by the weight sensor in each food storage unit with the weighing value. When the weight in the food storage unit reaches the weighing value, the opening and closing device is controlled to close;

[0040] Step 2, when all the opening and closing devices are closed, the central processing unit controls the stirring device in the grinding mechanism 3 to stir, and starts grinding after stirring evenly, and the ground food falls into the feeding tray 4 below the grinding mechanism ...

Embodiment 3

[0045] Magnetic Fe 3 o 4 / Ag nanoparticles preparation method: take 2g FeCl respectively 2 4H 2 O and 5.2 g FeCl 3 ·6H 2 O and 0.85mL of concentrated hydrochloric acid of 12.1 mol / L were dissolved in 200mLH 2 O, ultrasonic deoxygenation, and then the above solution was added dropwise to 250 mL, 0.75 mol / L NaOH solution, all the reaction temperature was 80 ° C, stirring, under N 2 under protection. As the reaction progressed, a black precipitate appeared in the reaction solution. The resulting precipitate was separated from the reaction medium by an external magnetic field, and washed three times with deionized water and twice with ethanol. Finally Fe 3 o 4 Nanoparticles were made into an ethanol solution with a concentration of 5g / L.

[0046] Dilute 25 mL of the above solution to 150 mL with ethanol and 100 mL of water, and sonicate the solution for 30 min. Then 0.4 mL of 3-aminopropyl triethoxy silicon was added dropwise to the above mixed solution, and stirred at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com