Vibration separation shell breaking machine

A technology of crushing shells and chips, which is applied in the direction of solid separation, shelling, and separation of solids from solids with airflow, which can solve the problems of complex manufacturing process, reduced collection efficiency, high production cost and maintenance cost, and achieve benefits The effect of popularizing use, improving collection efficiency, and facilitating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

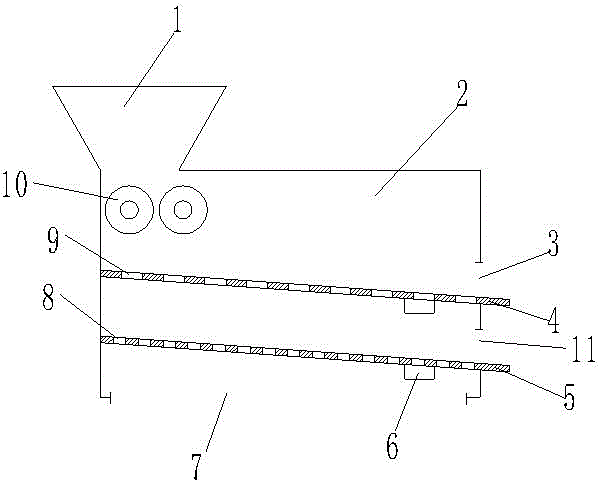

[0016] Such as figure 1 The shown vibrating separation shell cracker includes a box body 2, a feed port 1 and a shell crushing roller 10,

[0017] The feed port 1 is located at the top side of the box body 2 and communicates with the inside of the box body 2,

[0018] There are two shell crushing rollers 10, which are installed side by side below the feed port 1, and a peanut sieve plate 4 and a debris sieve plate 5 are arranged sequentially from top to bottom below the shell crushing roller 10. Some peanut sieve holes 9 are distributed on the peanut sieve plate 4, and some debris sieve holes 8 are distributed on the debris sieve plate 5, and the aperture of the peanut sieve hole 9 is larger than the aperture of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com