Fine and short tobacco stem expanding and recombining primary processing technology

A processing technology and tobacco stem technology, which is applied in the field of thin and short tobacco stem expansion and recombination processing technology, can solve the problems of increasing production cost, quantity and quality waste of tobacco stem resources, and achieve the effect of improving utilization rate and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

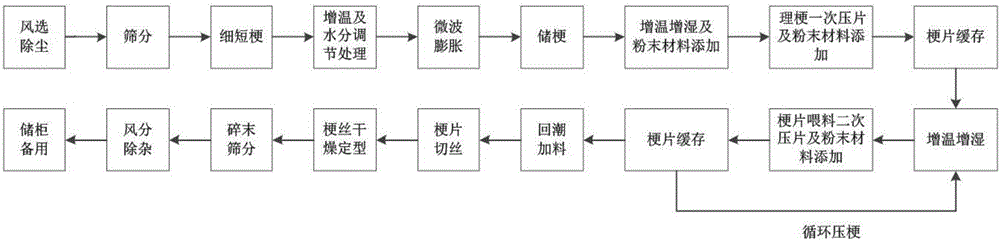

Method used

Image

Examples

Embodiment 1

[0044] A processing technology for expanding and recombining thin and short tobacco stems, comprising the following steps:

[0045] Step (1), air separation and dedusting of tobacco stems: air separation and dedusting of tobacco stem raw materials by air separation and impurity removal machine to obtain tobacco stems after impurity removal;

[0046] Step (2), sieving: sieving the tobacco stems obtained in step (1) by using a screening vibrating tank to obtain thin and short tobacco stems; the thin and short tobacco stems include tobacco stems with a diameter of less than 2.5mm and Tobacco stems less than 20 mm in length;

[0047] Step (3), warming and moisture adjustment treatment: use spiral warming and humidifying equipment to heat and humidify the thin and short tobacco stems obtained in step (2), until the temperature of the thin and short tobacco stems is raised to above 65°C, and the moisture The content is 10%;

[0048]Step (4), microwave expansion: using a drum-type ...

Embodiment 2

[0064] A processing technology for expanding and recombining thin and short tobacco stems, comprising the following steps:

[0065] Step (1), air separation and dedusting of tobacco stems: air separation and dedusting of tobacco stem raw materials by air separation and impurity removal machine to obtain tobacco stems after impurity removal;

[0066] Step (2), sieving: sieving the tobacco stems obtained in step (1) by using a screening vibrating tank to obtain thin and short tobacco stems; the thin and short tobacco stems include tobacco stems with a diameter of less than 2.5mm and Tobacco stems less than 20 mm in length;

[0067] Step (3), warming and moisture adjustment treatment: use spiral warming and humidifying equipment to heat and humidify the thin and short tobacco stems obtained in step (2), until the temperature of the thin and short tobacco stems is raised to above 65°C, and the moisture The content is 14%;

[0068] Step (4), microwave expansion: using a drum-type...

Embodiment 3

[0086] A processing technology for expanding and recombining thin and short tobacco stems, comprising the following steps:

[0087] Step (1), air separation and dedusting of tobacco stems: air separation and dedusting of tobacco stem raw materials by air separation and impurity removal machine to obtain tobacco stems after impurity removal;

[0088] Step (2), sieving: sieving the tobacco stems obtained in step (1) by using a screening vibrating tank to obtain thin and short tobacco stems; the thin and short tobacco stems include tobacco stems with a diameter of less than 2.5mm and Tobacco stems less than 20 mm in length;

[0089] Step (3), warming and moisture adjustment treatment: use spiral warming and humidifying equipment to heat and humidify the thin and short tobacco stems obtained in step (2), until the temperature of the thin and short tobacco stems is raised to above 65°C, and the moisture The content is 12%;

[0090] Step (4), microwave expansion: using a drum-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com