Coil-type filter membrane assembly and manufacturing method thereof

A production method and membrane filtration technology, applied in the field of water treatment, can solve the problems of increasing the difficulty of stacking and gluing, difficulty in automatic production, and low yield rate, so as to facilitate automatic production, increase effective use area, and high yield rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

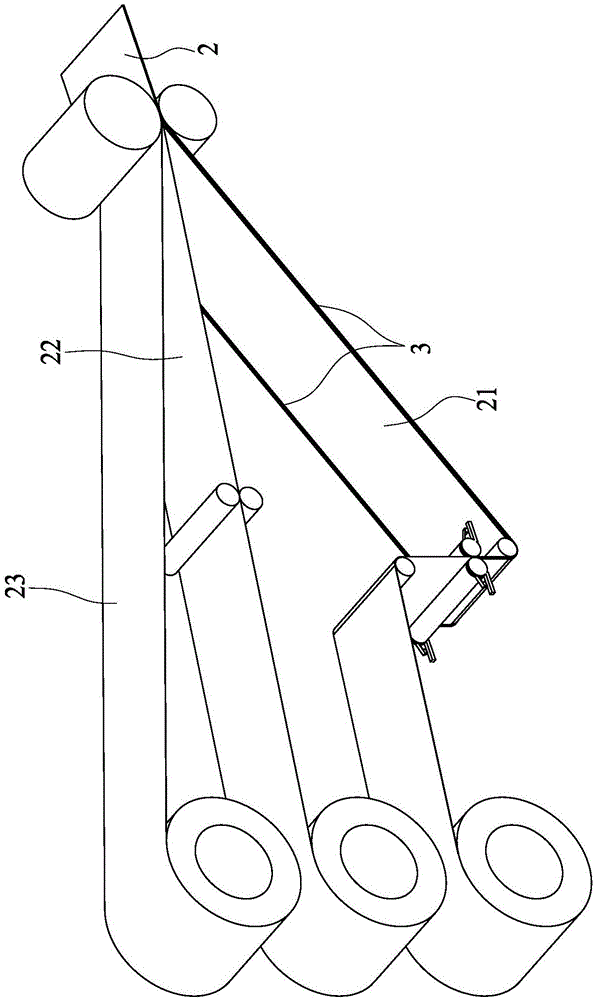

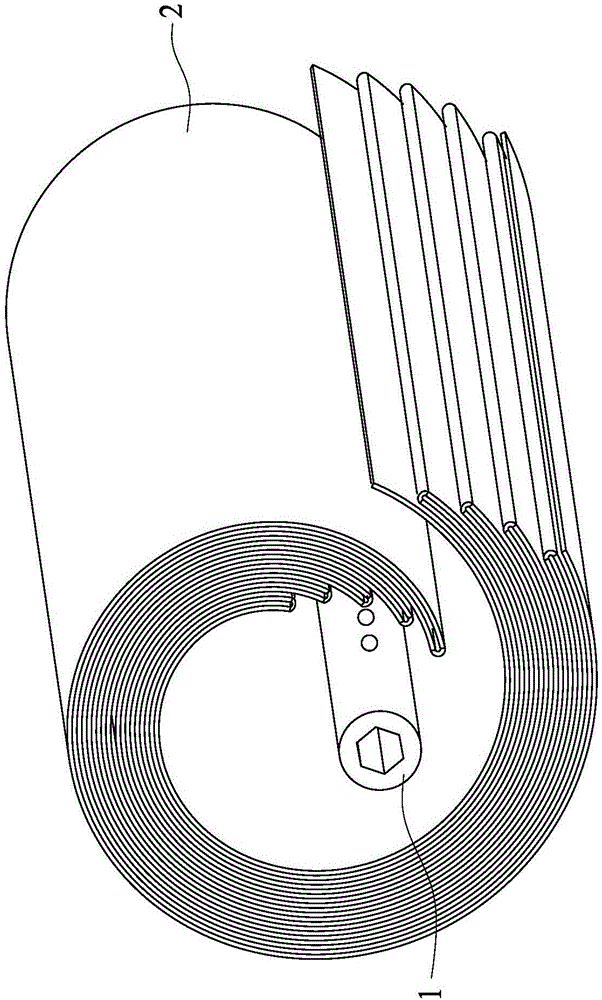

[0041] see Figure 1 to Figure 5 As mentioned above, a roll-type filter membrane assembly disclosed by the present invention includes a central tube 1 and a filter element 2 wound on the central tube 1, such as image 3 shown.

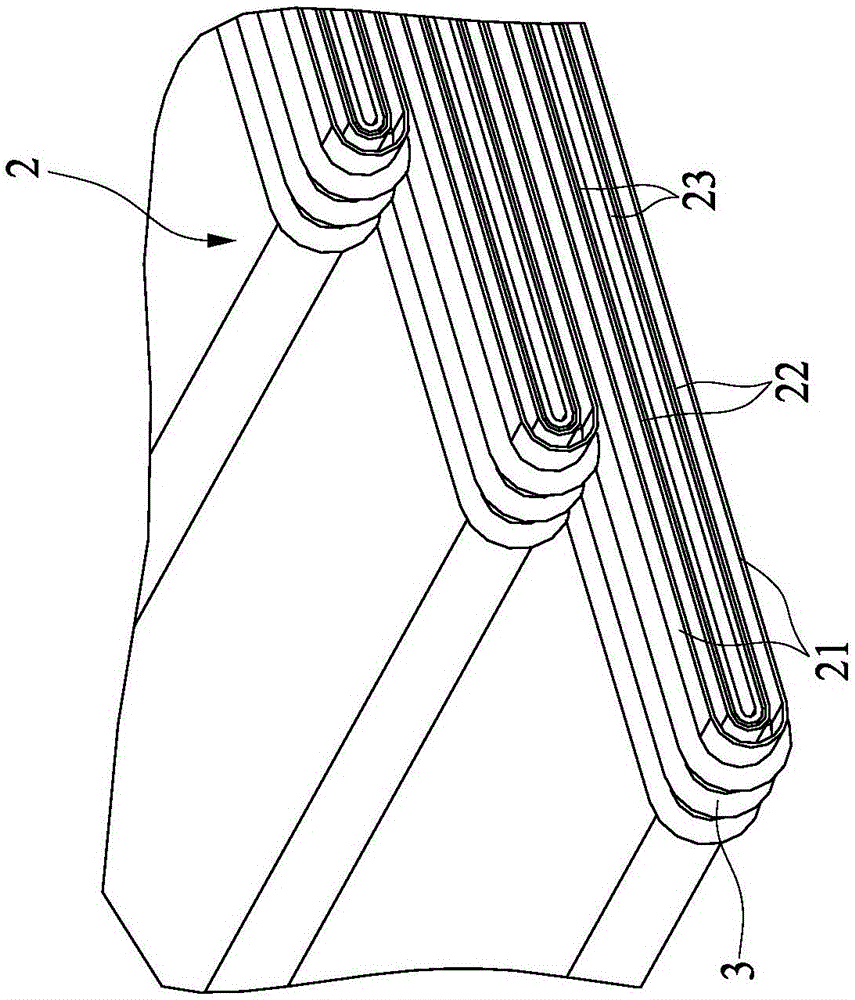

[0042] Wherein, the filter element 2 is formed by repeated stacking of continuous single sheets formed by successively stacking guide cloth 21, filter membrane 22 and grid 23, as figure 1 , figure 2 and image 3 As shown, one end of the stack with creases is tightly attached to the central tube 1 in turn, and the creases are parallel to the central tube 1 .

[0043] The side of the guide cloth 21 in contact with the filter membrane 22 is denser and smoother than the other side, so as to protect the filter membrane 22 .

[0044] The both sides of guide cloth 21 are coated with sealant 3, as figure 1 and figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com