Automatic transmitting sample grinding robot

A robot and automatic technology, applied in the direction of grinding workpiece support, surface polishing machine tool, grinding/polishing equipment, etc., can solve the problems of reducing experiment efficiency, affecting experiment progress, time-consuming and labor-intensive, etc., achieving high efficiency and convenient operation , Improve the experimental efficiency and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

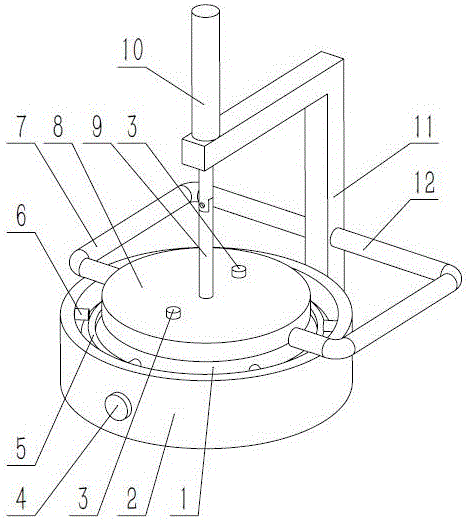

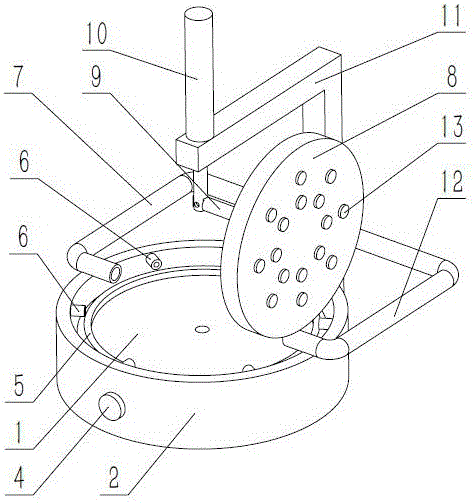

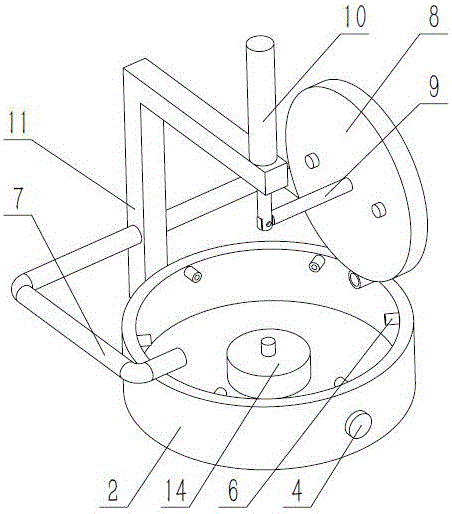

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a transmission sample automatic grinding robot includes a base 2 and a bracket 11, a rotating table 1 and a rotating motor 14, a sandpaper clamping ring 5, a sample mounting table 8 and a mounting table ejector rod 9, an elevating electric cylinder 10, Spray pipe 7 and grinding liquid pipe 12. The base 2 is disc-shaped, the support 11 is installed on one side of the base 2, the rotating motor 14 is installed at the center of the base 2, and the main shaft of the rotating motor 14 is vertically upward. The turntable 1 is disc-shaped and coaxially installed on the main shaft of the rotating motor 14 . The sandpaper clamping ring 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com