Raw brick blank airing support

A brick and board technology, applied in the field of brackets for drying raw bricks, can solve the problems of poor drying effect of raw bricks, low safety, time-consuming and laborious, etc., to facilitate ventilation and drying, improve ventilation coefficient, and reduce safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

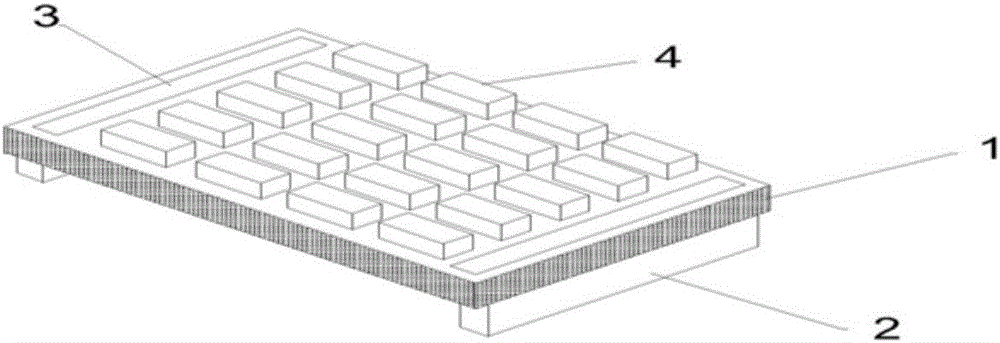

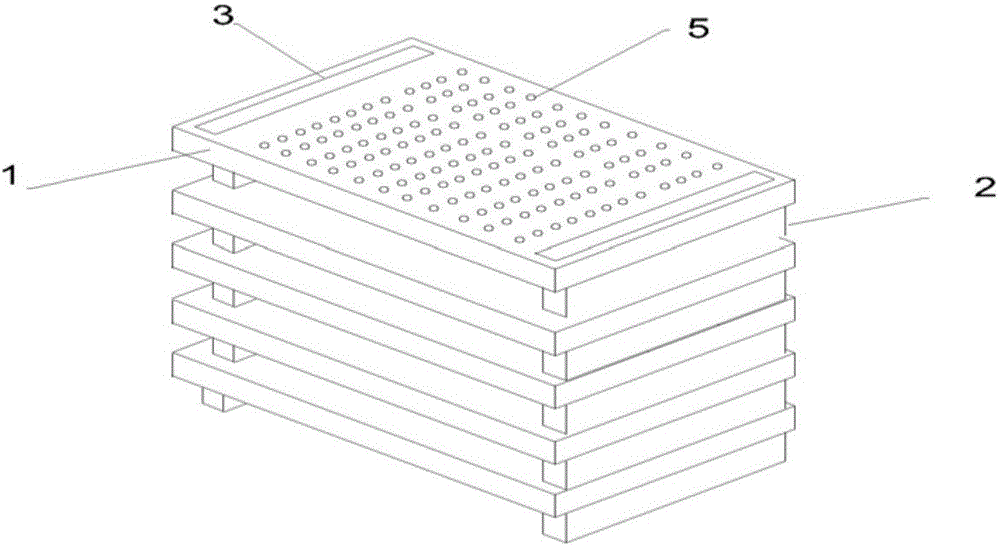

Embodiment 1

[0016] The invention discloses a raw brick adobe drying bracket (such as figure 2 shown), including multiple bulkheads (such as figure 1 As shown), the partition is composed of a board surface 1, a base and a slot 3. After the raw brick 4 is pressed and cut, it is transported to the partition board. The board surface 1 is a cuboid structure, and the base is composed of two parallel cuboids. Composed of crossbars 2, two cuboid crossbars 2 are respectively located at the lower part of both ends of the board surface 1, the axis of the two cuboid crossbars 2 is perpendicular to the axis of the board surface 1, the base and the board surface 1 are integrally formed, and the upper part of the board surface 1 There are also two slots 3, the two slots 3 are parallel to each other, the slots are rectangular slots, the slots 3 are respectively located directly above the rectangular parallelepiped bar 2 and the sizes are compatible with each other, when in use, the partition and the par...

Embodiment 2

[0019] In Example 2, the partition is composed of a board surface 1, a base and a slot 3, and the green brick 4 is transported to the partition board after being pressed and cut. The board surface 1 is a cuboid structure, and the base is composed of two mutually parallel Composed of cuboid crossbars 2, two cuboid crossbars 2 are respectively located at the lower part of both ends of the board surface 1, the axis of the two cuboid crossbars 2 is perpendicular to the axis of the board surface 1, the base and the board surface 1 are fixedly connected by bolts, and the board surface The upper part of 1 is also provided with two slots 3, the two slots 3 are parallel to each other, the slots are rectangular slots, the slots 3 are respectively located directly above the cuboid cross bar 2 and the sizes are mutually adapted, when in use, the partition It is connected and matched with the partition, that is, the base of the previous partition is inserted into the slot of the next partit...

Embodiment 3

[0021] In this embodiment, the partition is composed of a board surface 1, a base and a slot 3, and the raw brick 4 is transported to the partition board after being pressed and cut. The board surface 1 is a cuboid structure, and the base is composed of two parallel Composed of cuboid crossbars 2, two cuboid crossbars 2 are located at the lower part of both ends of the board surface 1, the axes of the two cuboid crossbars 2 are perpendicular to the axis of the board surface 1, the base and the board surface 1 are fixedly connected by screws, and the board surface The upper part of 1 is also provided with two slots 3, the two slots 3 are parallel to each other, the slots are rectangular slots, the slots 3 are respectively located directly above the cuboid cross bar 2 and the sizes are mutually adapted, when in use, the partition It is connected and matched with the partition, that is, the base of the previous partition is inserted into the slot of the next partition, and the upw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com