Maritime work arm folding crane rope looseness detecting device

A technology for loose rope detection and cranes, which is applied to cranes, measuring devices, optical devices, etc., can solve problems such as shortened service life, wire ropes detached from brackets, errors, etc., to ensure wave compensation accuracy, avoid engineering accidents, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

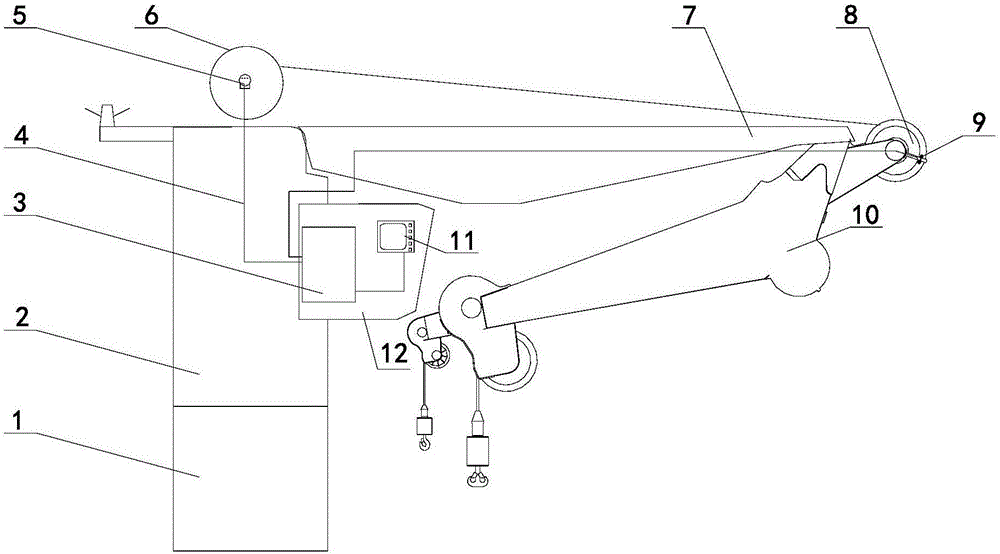

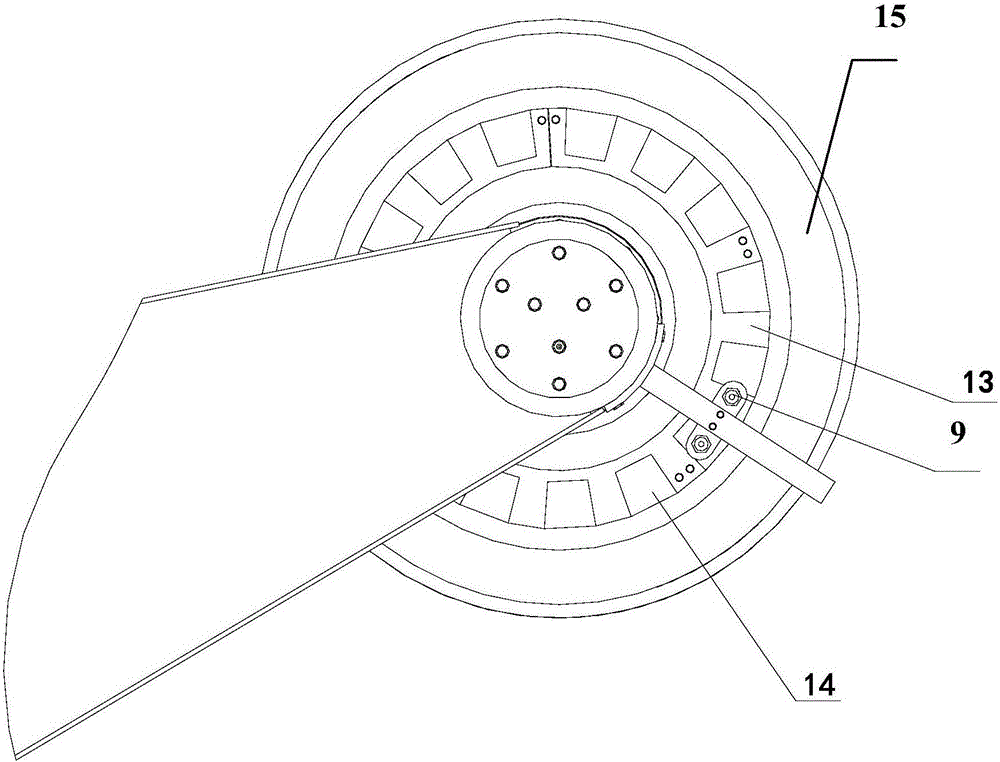

[0015] refer to figure 1 , which shows a loose rope detection device for a marine knuckle-arm crane according to an embodiment of the present invention, wherein the tower body 2 is arranged on the base 1, and the detection device includes: a main arm 7 and an auxiliary arm 10; a main winch 6, The main winch 6 is connected to one end of the main arm 7, and an absolute encoder 5 is installed on the rotating shaft of the main winch 6; the auxiliary arm pulley block 8, such as figure 2 As shown, the auxiliary arm pulley block 8 includes a photoelectric sensor 9, a pulley 15, and marking plates 13 and isolation plates 14 that are staggered along the circumferential direction of the pulley 15 surface. The photoelectric sensor 9 is installed on the side of the auxiliary arm pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com