Cast polyurethane storage battery protection case and manufacturing method thereof

A storage battery and polyurethane technology, which is applied in the isolation of batteries from their environment, battery pack components, circuits, etc., can solve problems such as high thermal conductivity, high viscosity of the system, and brittle foam, and achieve excellent flame retardancy and high temperature resistance Improvement and foam cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

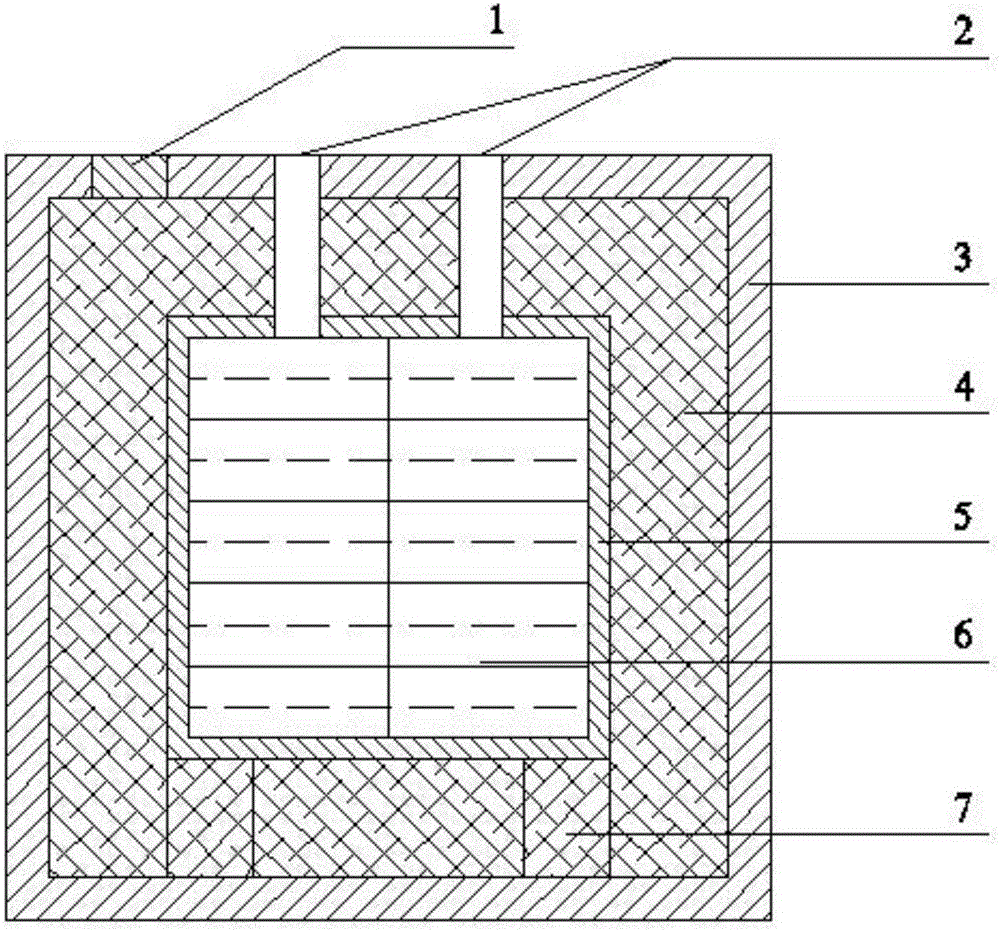

[0050]The cast polyurethane battery protection box includes an inner shell 5 and an outer shell 3, a support block 7 is placed inside the outer shell, an inner shell is placed on the support block, and the battery 6 is placed in the inner shell 5, the inner shell and the outer shell The body is provided with a wiring hole 2, and the outer shell is provided with a sprue 1, which is characterized in that: the inner shell 1 and the outer shell 3 are filled with a polyurethane hard foam insulation sandwich layer 2, and the polyurethane hard foam The insulation sandwich layer 4 is formed by pouring inorganic hybrid melamine polyurethane rigid foam material, and the support block is prepared by pouring and molding inorganic hybrid melamine polyurethane rigid foam material with the same composition as the polyurethane rigid foam insulation sandwich layer;

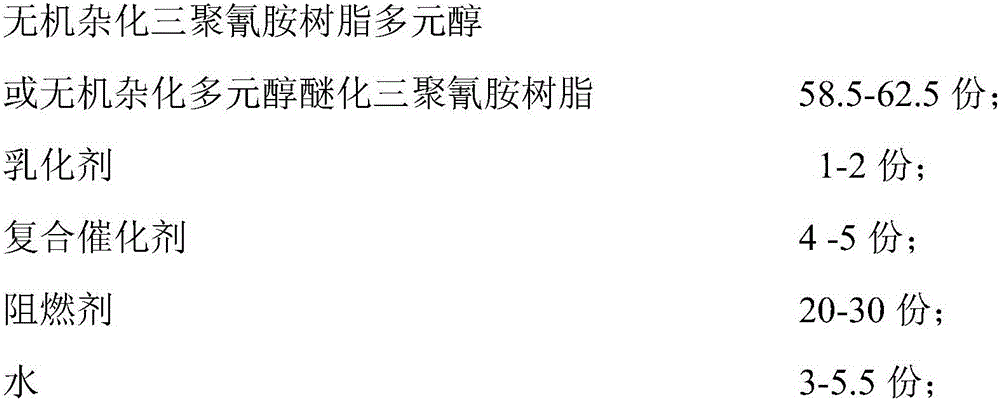

[0051] Inorganic hybrid melamine polyurethane rigid foam material is made of inorganic hybrid melamine polyurethane combined with...

Embodiment 2

[0086] The cast polyurethane battery protection box includes an inner shell 5 and an outer shell 3, a support block 7 is placed inside the outer shell, an inner shell is placed on the support block, and the battery 6 is placed in the inner shell 5, the inner shell and the outer shell The body is provided with a wiring hole 2, and the outer shell is provided with a sprue 1, which is characterized in that: the inner shell 1 and the outer shell 3 are filled with a polyurethane hard foam insulation sandwich layer 2, and the polyurethane hard foam The insulation sandwich layer 4 is formed by pouring inorganic hybrid melamine polyurethane rigid foam material, and the support block is prepared by pouring and molding inorganic hybrid melamine polyurethane rigid foam material with the same composition as the polyurethane rigid foam insulation sandwich layer;

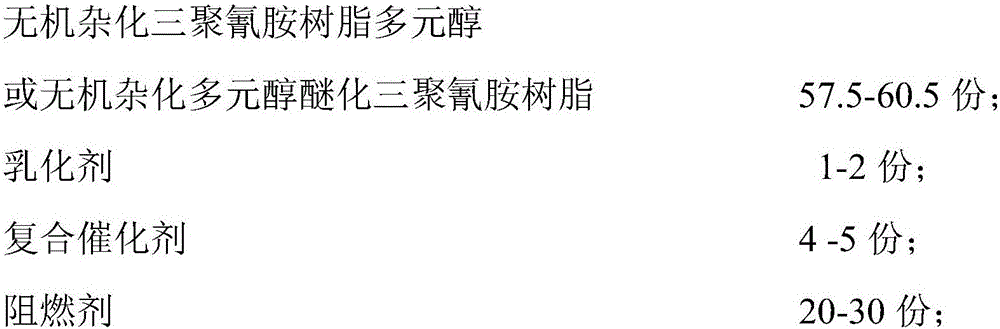

[0087] Inorganic hybrid melamine polyurethane rigid foam material is made of inorganic hybrid melamine polyurethane combined wit...

Embodiment 3

[0122] The cast polyurethane battery protection box includes an inner shell 5 and an outer shell 3, a support block 7 is placed inside the outer shell, an inner shell is placed on the support block, and the battery 6 is placed in the inner shell 5, the inner shell and the outer shell The body is provided with a wiring hole 2, and the outer shell is provided with a sprue 1, which is characterized in that: the inner shell 1 and the outer shell 3 are filled with a polyurethane hard foam insulation sandwich layer 2, and the polyurethane hard foam The insulation sandwich layer 4 is formed by pouring inorganic hybrid melamine polyurethane rigid foam material, and the support block is prepared by pouring and molding inorganic hybrid melamine polyurethane rigid foam material with the same composition as the polyurethane rigid foam insulation sandwich layer;

[0123] Inorganic hybrid melamine polyurethane rigid foam material is made of inorganic hybrid melamine polyurethane combined wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com