Water-based protective spray film

A spray film and water-based technology, applied in the direction of coating, etc., can solve the problems of reduced tearability, damage to the original car paint, monotonous color, etc., and achieve good protection function, good weather resistance, and high transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

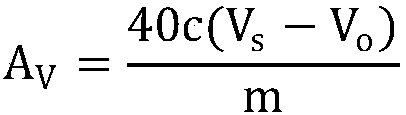

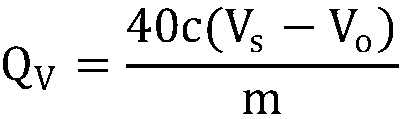

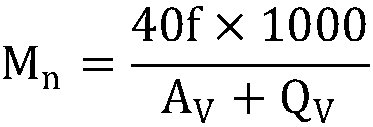

Image

Examples

preparation example Construction

[0030] The preparation process of aliphatic polyester polyurethane of the present invention is:

[0031] (1) Add organic dibasic acid and polyhydric alcohol into a 500mL four-necked flask, pass nitrogen gas until the air is completely exhausted, then heat to 155°C, keep warm for 1h, then heat the flask to 230°C, keep warm for 3h, Analyze the acid value and hydroxyl value, stop the reaction when the number average molecular weight reaches about 2000, and obtain the first step product;

[0032] (2) In a three-neck flask equipped with a mechanical stirrer, a thermometer, and a condenser tube, add the product of the first step and polyisocyanate containing ether bonds, heat to 60°C, keep the temperature for 2 hours, then add dimethylolpropionic acid and 2 Drop dibutyltin dilaurate, heat up to 85°C, keep warm for 3h, then add N-methylpyrrolidone, react for 3h, then cool down to 40°C, add triethylamine and stir quickly, disperse in deionized water, and vacuum dry , that is.

[003...

Embodiment

[0087] a1 Aliphatic polyester polyurethane, prepared from raw materials containing organic dibasic acids, polyols and polyisocyanates. Among them, the organic dibasic acid is dodecanedioic acid, the polyol is ethylene glycol, and the polyisocyanate is 4',5'-diisocyanate benzo-15-crown-5.

[0088] The preparation process of 4',5'-benzo-15-crown-5 diisocyanate is as follows:

[0089] (1) Weigh 10 mL of pentaethylene glycol and place it in a 250 mL double-necked flask equipped with a reflux condenser, add 50 mL of thionyl chloride and 3 drops of DMF. Heating to reflux for 15 hours, cooling to room temperature after the reaction, and drying the thionyl chloride with a rotary evaporator to obtain dichloropentaethylene glycol.

[0090] (2) Put 0.01mol 4,5-diaminocatechol and 0.012mol dichloropentaethylene glycol in a 250mL round bottom flask, then add 0.01mol sodium hydroxide and 0.005mol lithium hydroxide, and use 100mL butanol as Solvent, heated to reflux for 2h. After the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com