Pretreatment method for guaranteeing normal ultrasonic detection inside cast-in-situ bored pile

A technology of bored piles and ultrasonic waves, which is applied in the test of basic structure, construction, and basic structure engineering, etc., to achieve the effect of low cost, strong practicability, and easy technology to master.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

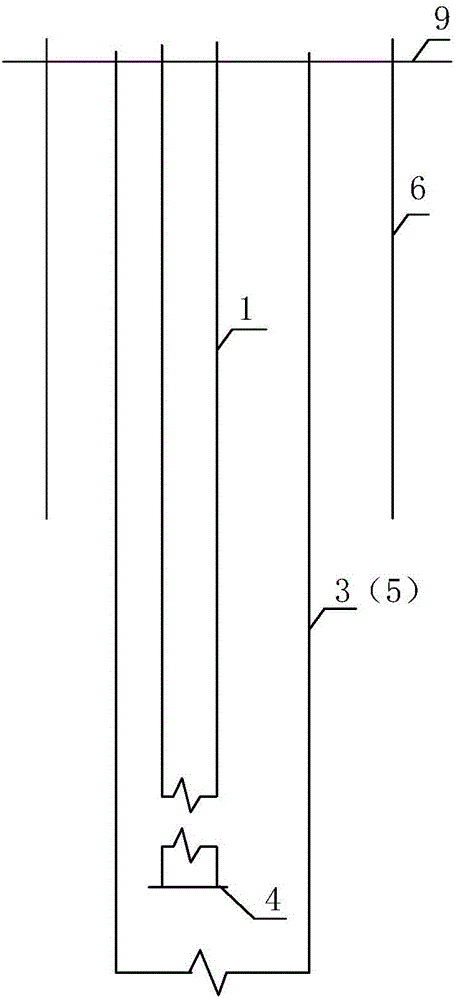

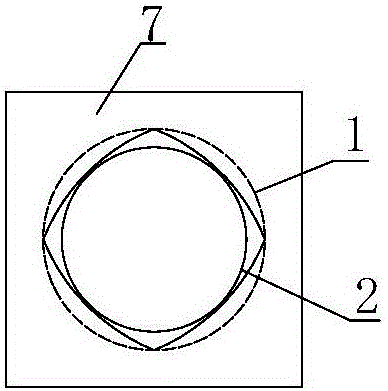

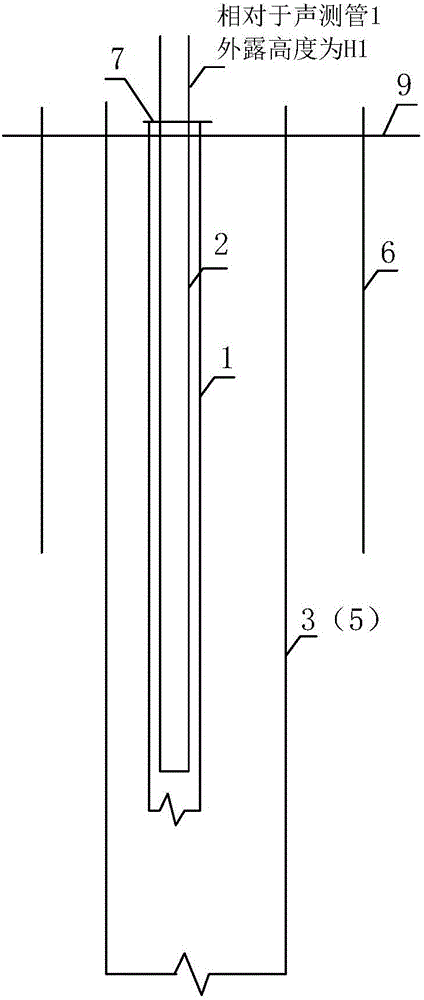

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

[0021] The design idea of the present invention is: in order to ensure the smoothness of the acoustic measuring tube of the bored pile and ensure the normal detection of the pile foundation, the acoustic measuring tube in the bored pile is filled with suitable materials, accompanied by suitable plugging measures, to determine During the docking process of the pile foundation reinforcement cage and the acoustic tube at the wellhead, even if there is a small amount of trachoma in the acoustic tube, which may enter or infiltrate into the pouring material, it will not block the acoustic tube and affect the ultrasonic detection of bored piles. The present invention proposes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com