Overlapping assembling integrated basement of beam-free floor system

A beamless floor and basement technology, applied in floors, underwater structures, artificial islands, etc., can solve problems such as large demand for formwork and scaffolding, uncontrollable concrete quality, and difficulty in concrete operation, achieving labor costs and The effect of low material cost, good in-situ casting integrity, and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

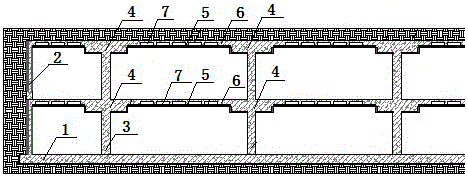

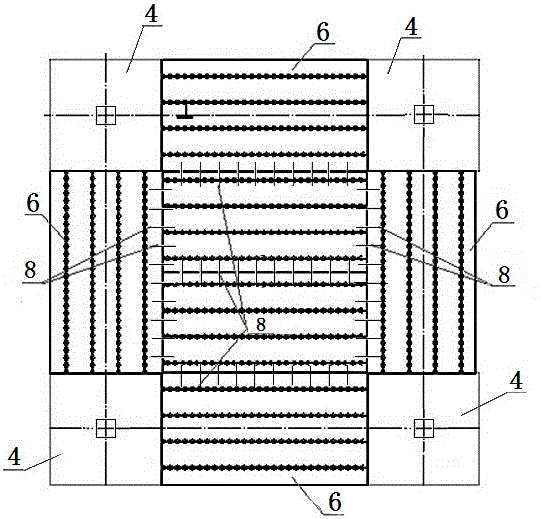

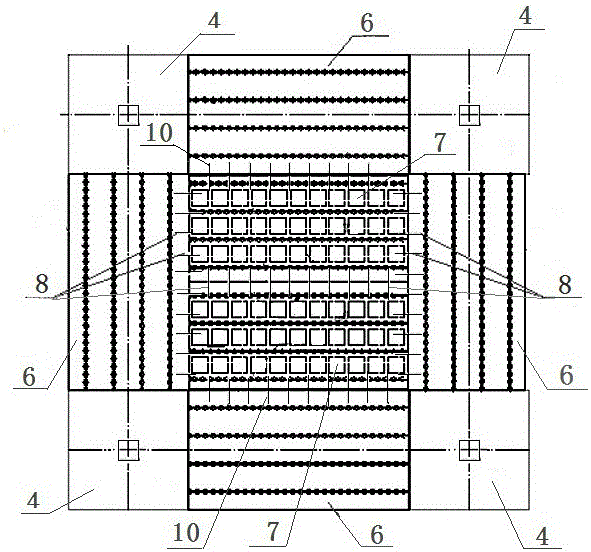

[0020] see figure 1 , figure 2 , image 3 , a laminated and assembled integral basement of a beamless floor system according to the present invention, the basement floor is a fully cast-in-place concrete floor or a prefabricated laminated floor, the side walls of the basement are prefabricated laminated sandwich walls, and several cast-in-place concrete walls are arranged in the middle of the basement. The cast-in-place column has a column cap, the basement roof adopts a beamless laminated solid floor or a beamless laminated hollow floor, and the basement negative n floor adopts a beamless laminated hollow floor or a beamless laminated solid floor, n is a natural number; the beamless laminated solid floor or beamless laminated hollow floor of the basement roof and the top of the prefabricated laminated sandwich wall of the side wall and the top column cap of the cast-in-place column are connected as a whole through cast-in-place, and the basement load The n-story beamless l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com