Scroll compressor with unloading device and assembly method thereof

A scroll compressor and unloading device technology, which is applied in assembly machines, rotary piston machines, manufacturing tools, etc., can solve problems such as loud noise and damage, and achieve the effects of reducing wear, ensuring normal operation, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Scope of application of the present invention: suitable for high-power scroll compressors.

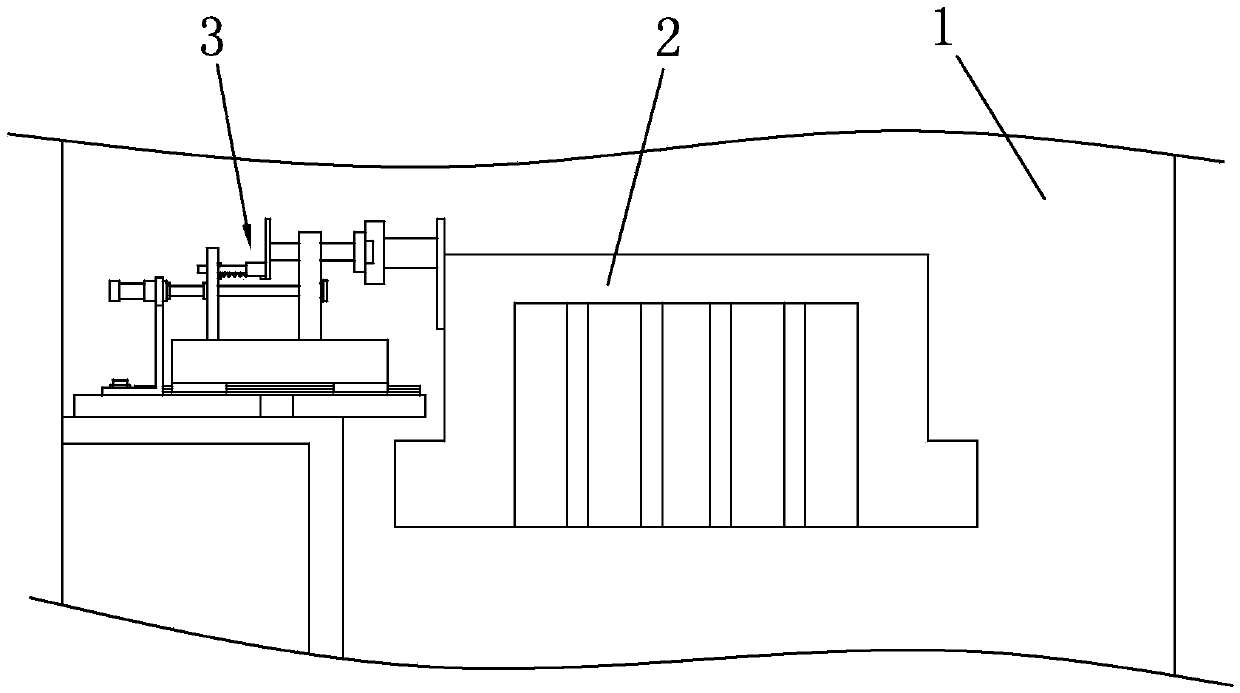

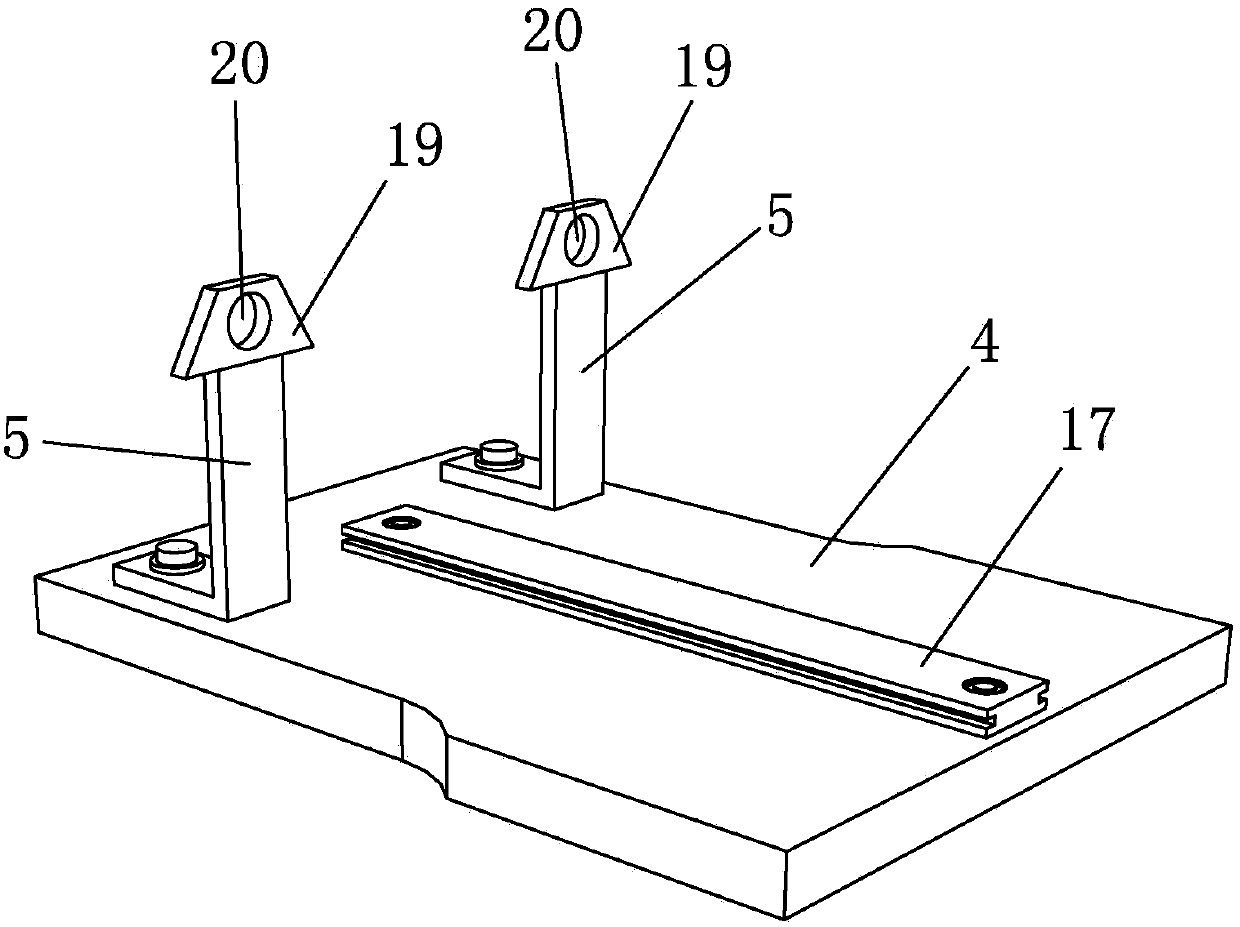

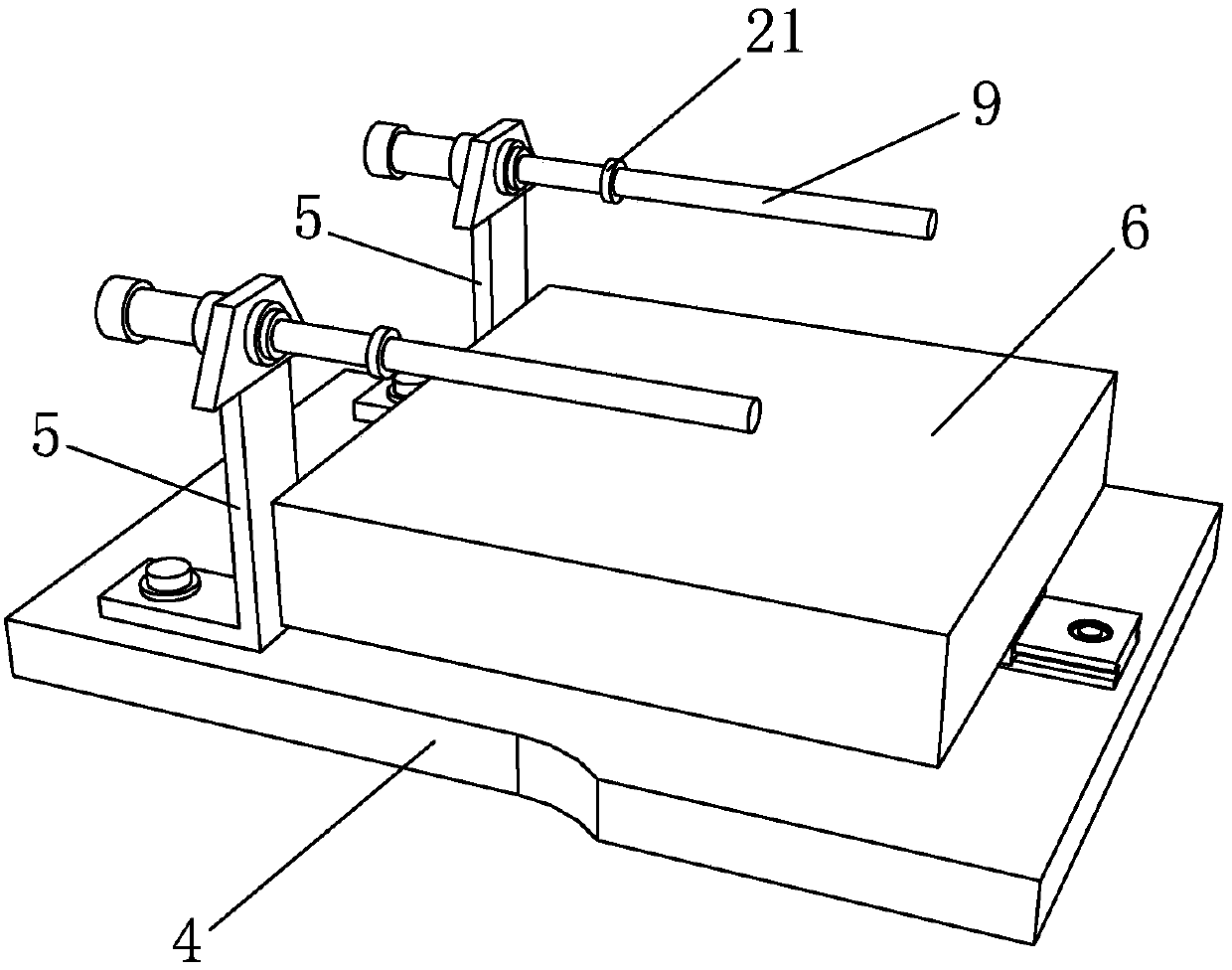

[0034] like Figure 1 to Figure 6 As shown, a scroll compressor with an unloading device includes a body 1 , a scroll assembly 2 is arranged in the body 1 , and an unloading device 3 is arranged in the body 1 . The unloading device 3 includes a base 4 , a support base 5 , an installation base 6 , a first buffer mechanism 7 and a second buffer mechanism 8 . The mounting base 6 is slidably connected to the base 4, the top of the base 4 is provided with a slide rail 17, the bottom of the mounting base 6 is provided with a slider 18, and the slider 18 is slidably connected to the slide rail 17, so that the mounting base 6 can be mounted on the base 4. According to the position of the supporting seat 5, adjust the position of the mounting seat 6 on the base 4. The support base 5 is provided with a support rod 9, the support base 5 is provided with a fixed head 19, the fixed head 19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com