Floating ball type self-balance dewatering device and dewatering circulation area calculating method thereof

A flow area, self-balancing technology, applied in the direction of steam traps, mechanical equipment, etc., can solve the problems of unable to maintain the water level in the heater, easy to malfunction, and many mechanical moving parts, etc., to achieve a simple structure and a wide range of applications , The effect of fewer mechanical moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

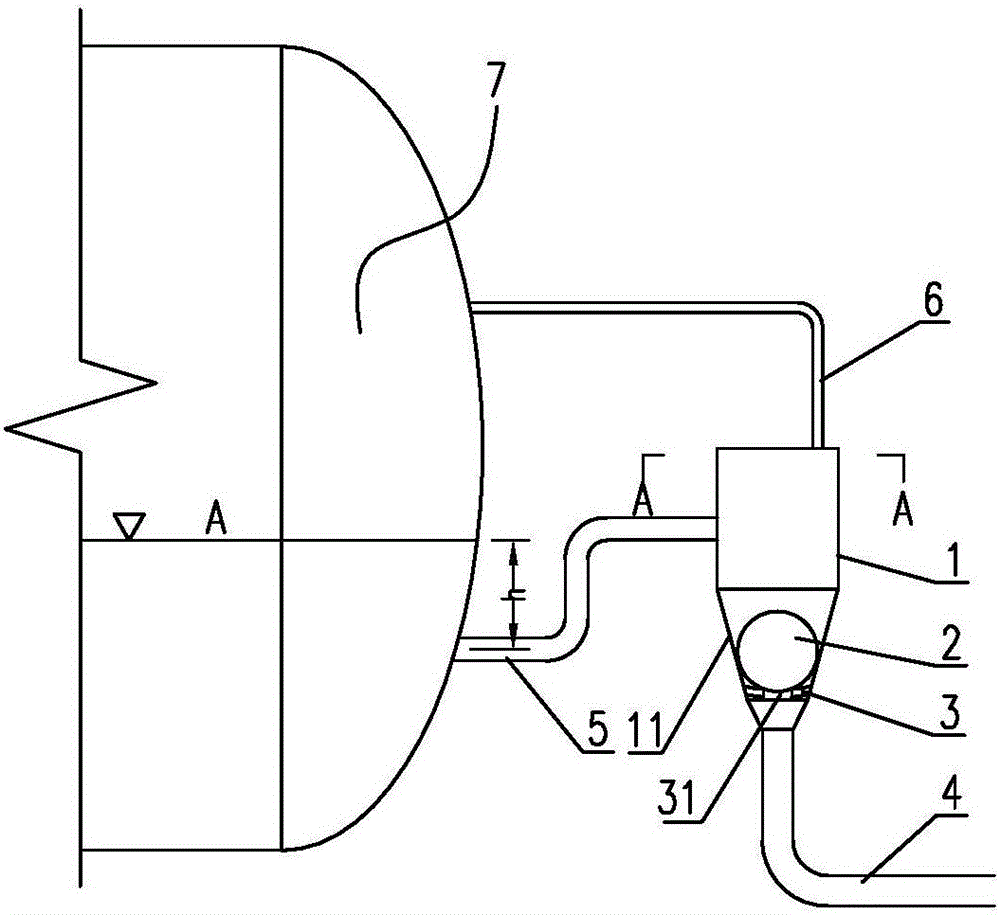

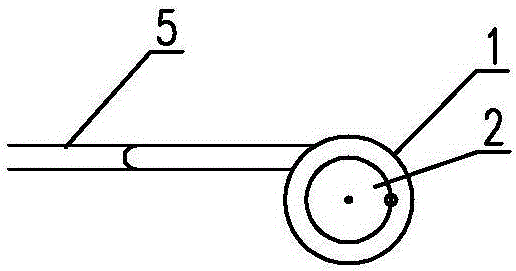

[0046] refer to figure 1 with figure 2The floating ball type self-balancing drainage device shown includes a housing 1, a floating ball 2, a drainage pipe 4, a water inlet pipe structure 5 and an air balance pipe 6, and the housing 1 is arranged higher than the heat exchanger 7 in the drainage system At the normal water level position A, a water outlet 11 is provided at the bottom of the housing 1, and a floating ball 2 is arranged at the water outlet 11 to open or close the water outlet 11. The air space position on the upper part of the heater 7 is to form an aerodynamic balance structure to balance the air pressure between the housing 1 and the heat exchanger 7; The structure 5 communicates with the water outlet of the heat exchanger 7 to transport the hydrophobic water of the heat exchanger 7 to the shell 1; the drain end of the shell 1 is set on the bottom surface of the shell 1 and is used for draining the water by communicating with the drain pipe 4 ; Form the hydrau...

specific Embodiment 2

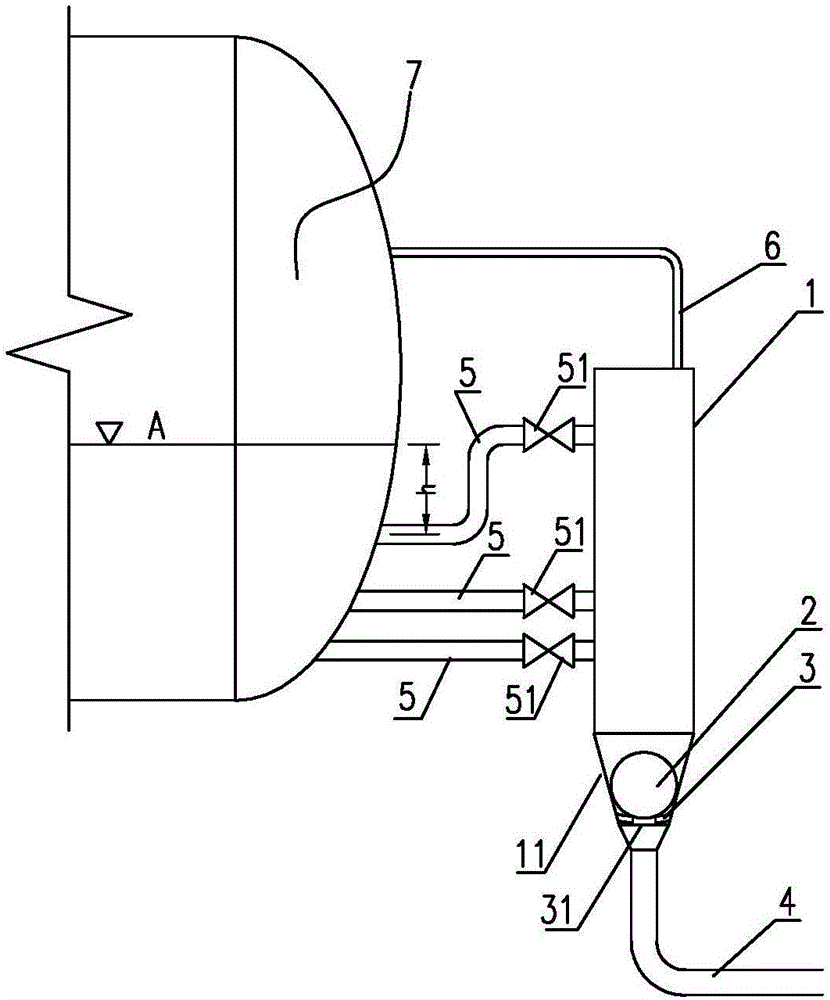

[0069] The technical features of this implementation are: image 3 As shown, the water inlet pipeline structure 5 is composed of a plurality of water pipes, one end of the water inlet pipeline 5 is connected to the heat exchanger 7, and the other end is connected to the connecting pipe of the housing 1, and each connecting pipe connects the drain of the heat exchanger 7 transported into housing 1. There are several guide grooves distributed around the inner wall of the water outlet 11, and the guide grooves are used to guide the water above the floating ball 2 to the bottom of the floating ball 2 to form the floating force of the floating ball. A plurality of water inlet pipes 5 with different elevations can be arranged between the shell 1 and the heat exchanger 77, and a switching valve 51 is arranged on the water inlet pipe 5 to realize automatic control of various water levels. All the other are the same as the above embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com