Composite vibrating wire sensor device for displacement measurement of three directions

A vibrating wire sensor, displacement measurement technology, applied in measurement devices, instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve the problems of large amplitude, long excitation time, large energy consumption, etc. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

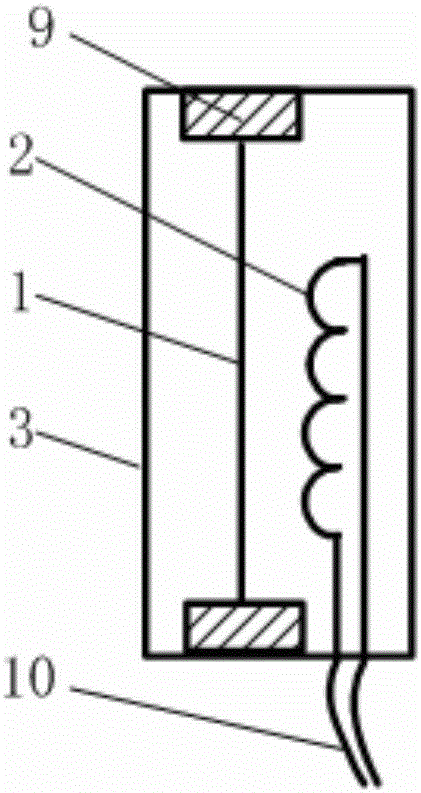

[0036] Such as figure 1 As shown, the vibrating wire sensor belongs to the frequency sensor, which can be equivalent to a vibrating steel string whose frequency at both ends changes with the tension of the steel wire, including the vibrating wire 1, the coil 2, the sensor housing 3 and the lead wire 10, and the vibrating wire 1 is fixed on On the positioning support 9 at both ends of the sensor housing 3, the coil 2 is arranged in the middle of the vibrating wire 1, the circuit generates an excitation signal, the driving coil generates magnetic force to drive the vibrating wire 1 to vibrate, and detects the vibration of the vibrating wire 1.

[0037] Under electric excitation, the vibrating wire 1 vibrates according to its natural frequency, and changing the tension F of the vibrating wire 1 can obtain different vibration frequencies F, that is, the relationship between tension and resonance frequency is a single-valued function. When the length of the vibrating wire under ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com