Waveguide beam conditioning for high powered laser

A laser and beam technology, applied in laser optical equipment, optical fiber light guides, hollow light guides, etc., can solve the problems of inability to uniformly control the ellipticity of laser tubes and aggravate beam astigmatism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

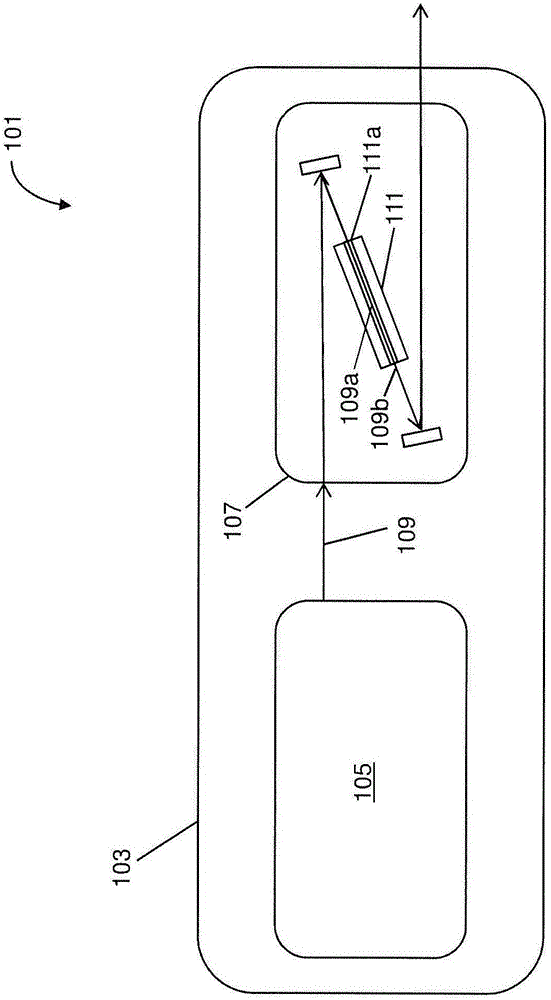

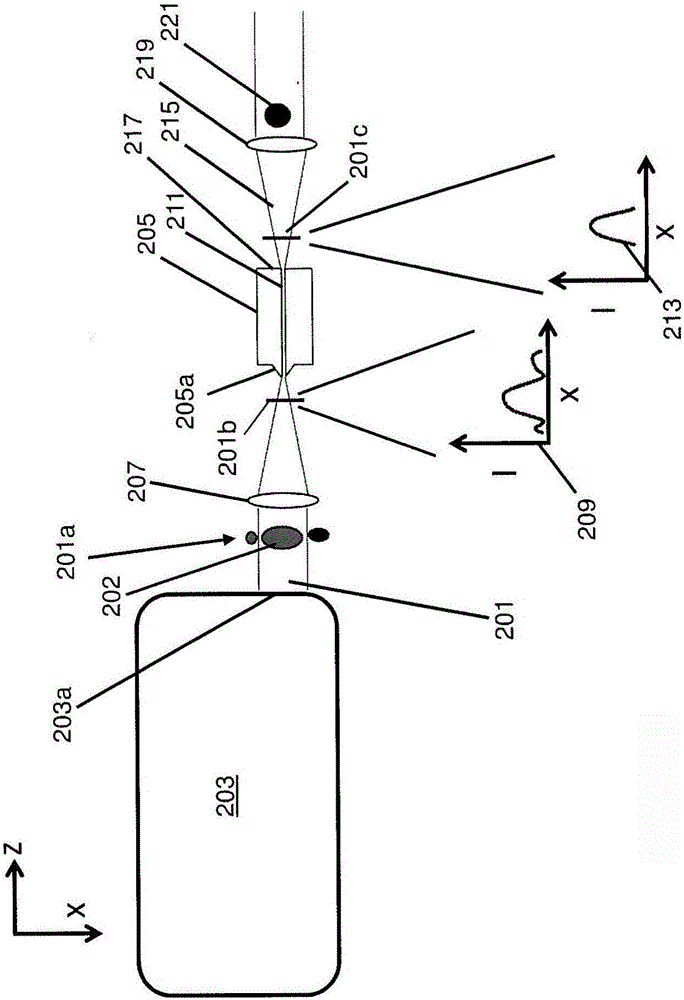

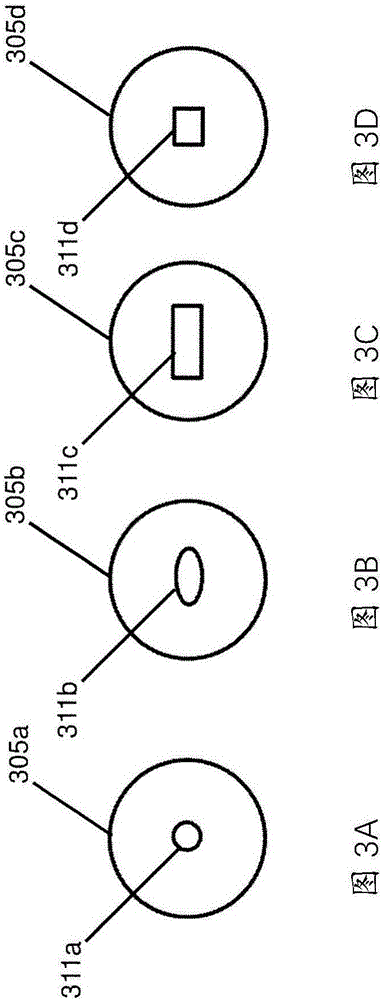

[0024] The specific implementation of the waveguide adjustment for the high-power laser will now be described in detail with reference to the accompanying drawings. Similar elements in the various drawings (also referred to as figures) are denoted by similar reference numerals to achieve consistency.

[0025] In the following detailed description of the embodiments, many specific details are shown in order to provide a more thorough understanding of the laser tube with baffles. However, it will be obvious to those of ordinary skill in the art that these embodiments can be practiced without these specific details. In other cases, well-known features are not described in detail so as not to unnecessarily complicate the description.

[0026] Generally speaking, one or more embodiments of the present disclosure relate to waveguide pinhole beam modifiers and laser systems, and methods for reducing or eliminating ellipticity and astigmatism and using waveguide pinhole beam modifiers to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com