Rolling bearing friction moment parameter uncertainty estimation method

A technology with uncertain parameters and friction torque, which can be used in electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

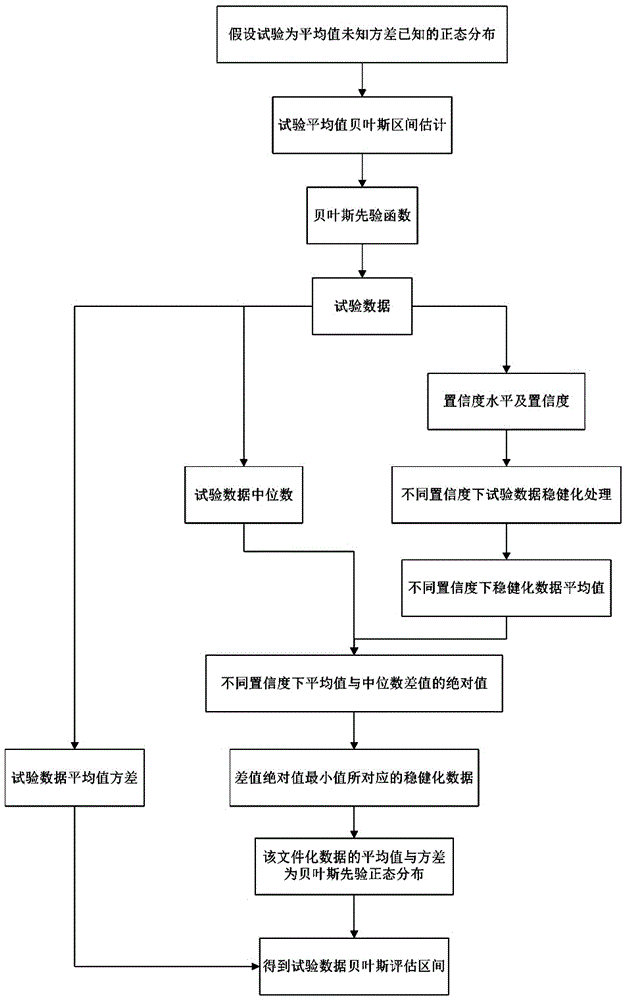

[0085] The flow chart of the inventive method is as image 3 As shown, the specific implementation steps are:

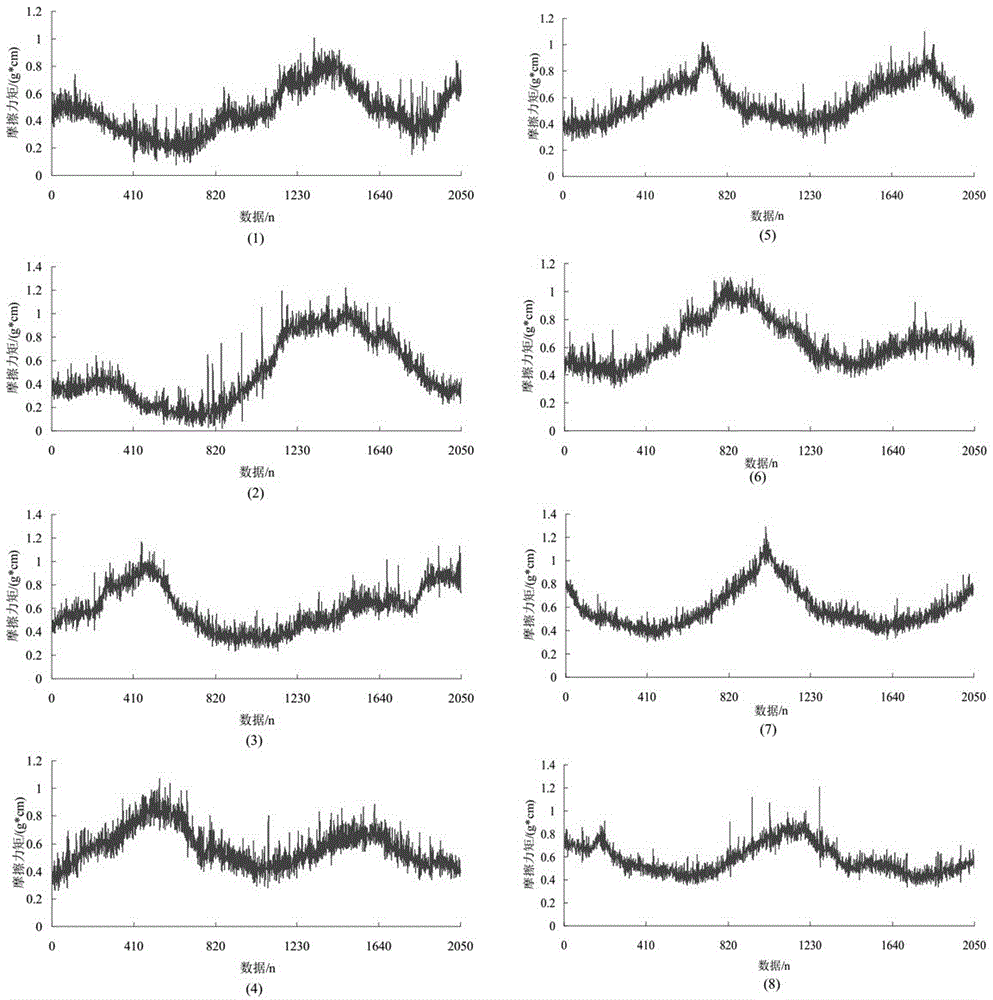

[0086] (1) Select 8 sets of aerospace bearings HKTA, measure their friction torque, and obtain the friction torque data of the bearings

[0087] ①Experimental conditions: room temperature 20℃~25℃, relative humidity above 55%, clean environment, no vibration of foundation.

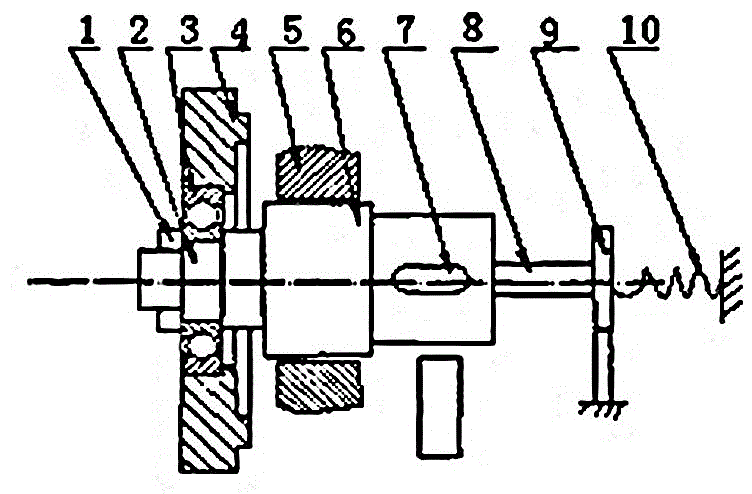

[0088] ②Friction torque measurement method: such as figure 2 , the outer ring of the tested bearing 3 is installed in the replacement sleeve 4, and is driven to rotate together with the replacement sleeve 4 by the transmission system, and the inner ring of the tested bearing 3 is fixed on the main shaft 6 by the replacement spindle 2 and the pin 1. The spring 10 applies an axial load through the hanging wire 8 . The main shaft 6 is installed in the air bearing 5 (the friction torque between the main shaft 6 and the air bearing 5 is extremely small). When the outer ring rotates, due to the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com