Hypersonic velocity wing robust optimization design method considering machining errors

A hypersonic and robust optimization technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of poor robustness and low efficiency of optimization results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Hereinafter, design examples of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the selected examples are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

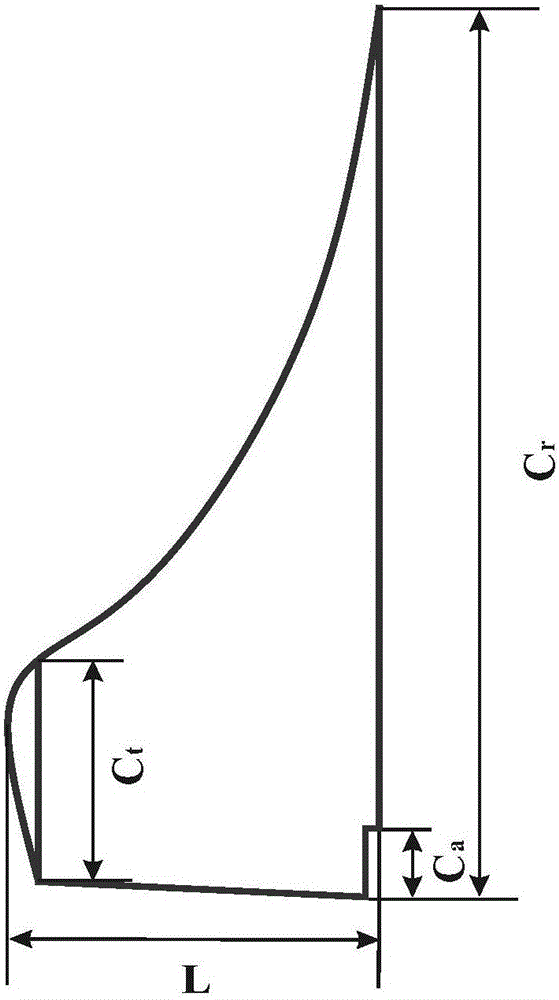

[0072] (1) Taking the wing of a hypersonic aircraft like X-37B as the research object, first determine the plane profile parameters of the hypersonic wing, including the wing root chord length C r , aileron width C a , wing aspect ratio AR and slightly root ratio TR. In addition, the wingtip chord length C t =C r · TR, wing half-span The plane profile of the wing is as figure 1 The initial values of relevant parameters are shown in Table 4.

[0073] Table 4 Initial values of wing plane profile parameters

[0074]

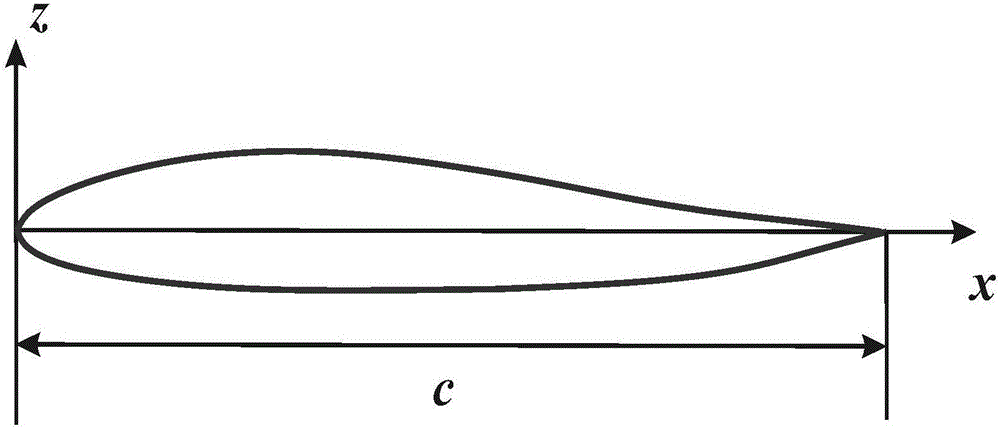

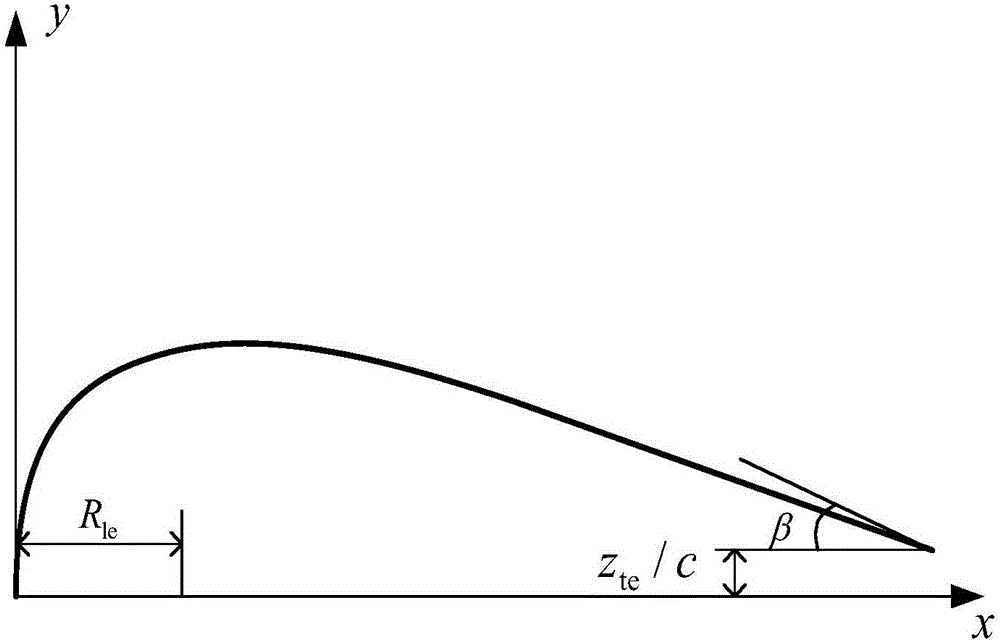

[0075] (2) The Clark-Ys airfoil is used as the standard airfoil (see figure 2 ), use the type function / shape function conversion method to set the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com