Single-direction plug and socket connection assembly

A technology of plug socket and plug assembly, which is applied in the direction of connection, contact parts, base/housing, etc., can solve the problems of incompatibility, small overload current, easy arc generation, etc., achieve high stability and reliability, prevent The effect of preventing electric shock by mistaken insertion and preventing dust from entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

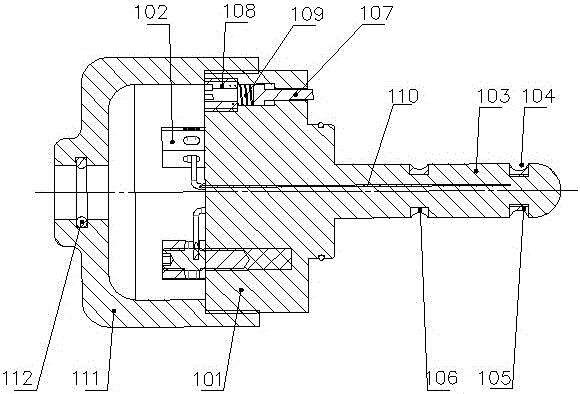

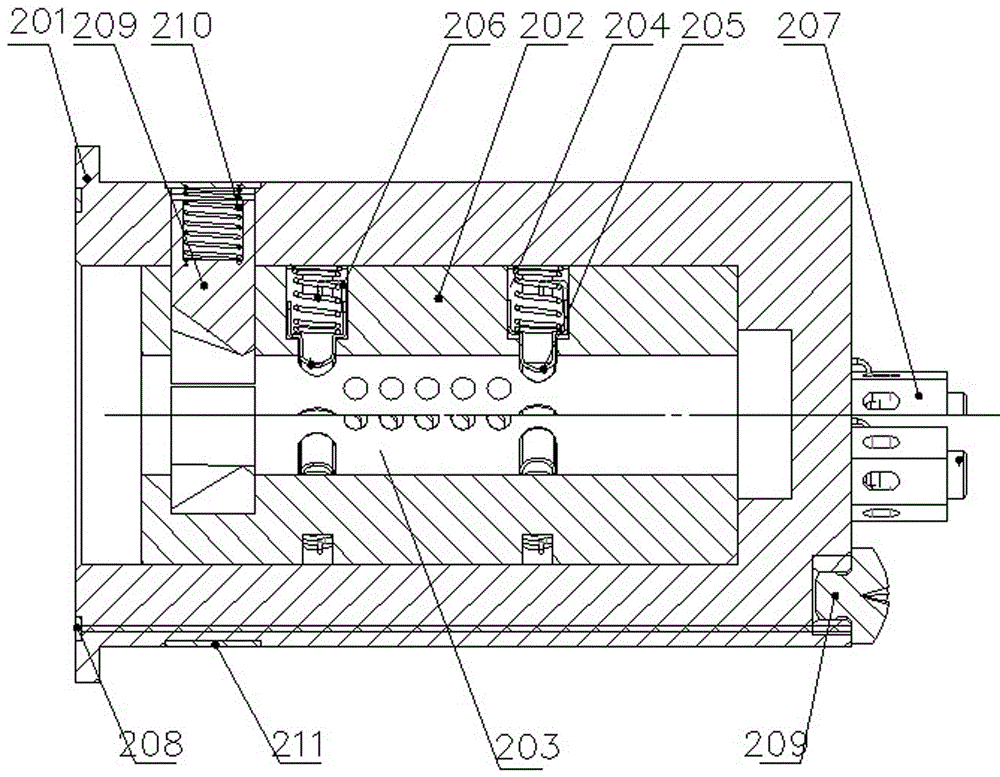

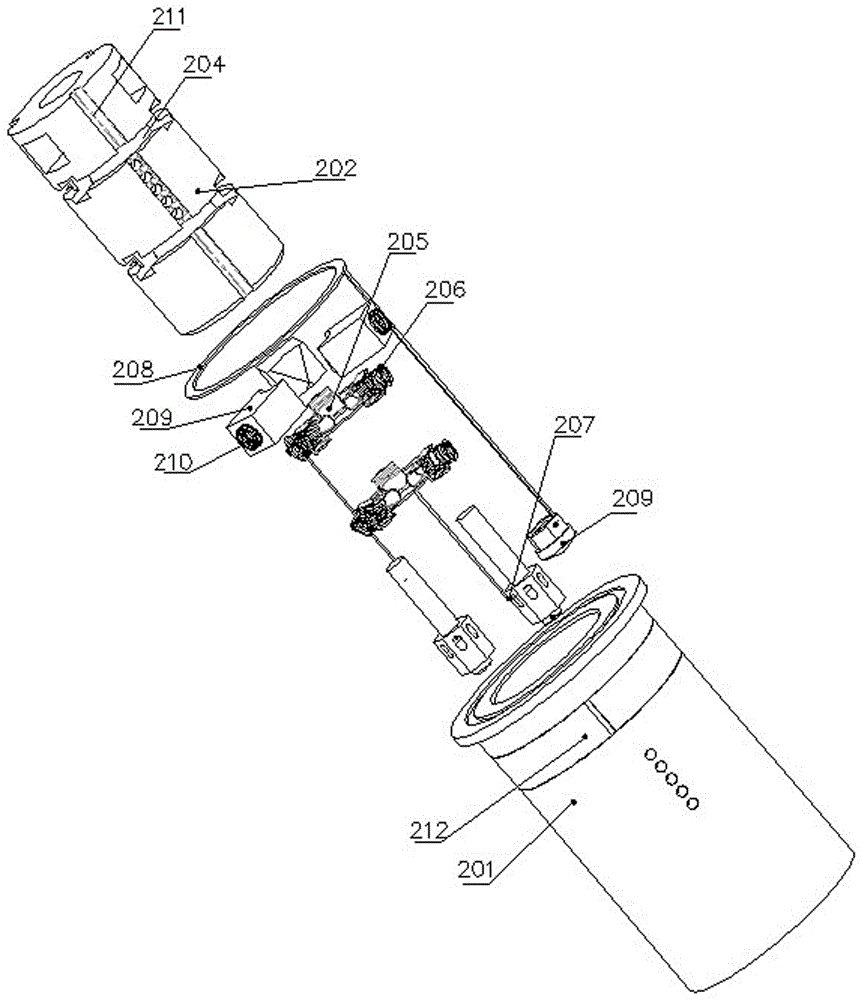

[0020] A one-way plug socket assembly, including a plug assembly 1 and a socket assembly 2, the plug assembly 1 includes a one-way plug housing 101, and two male ends are fixedly installed on the bottom surface of the plug housing 101 A terminal post 102, a columnar plug body 103 is coaxially provided on the top surface of the plug housing 101, and two rings and an annular groove 104 are coaxially arranged on the plug body 103, and concave grooves are respectively installed in the two annular grooves. The ring-shaped live wire contact 105 and the neutral wire contact 106 are provided with an axial wire groove 110 in the plug body, and the two male terminals 102 are respectively connected to the corresponding contacts through wires from the wire groove 110; The body is provided with an axial countersunk hole deviated from the axis, and a grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com