Cylindrical electro-hydro dynamic micro-pump and manufacturing method therefor

A cylindrical, electrofluidic technology, applied in the direction of electric components, manufacturing motor generators, electrical components, etc., can solve the problems of inaccurate flow control, large noise, large volume, etc., achieve efficient and stable operation, simple processing and preparation, and enhanced The effect of drag and drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

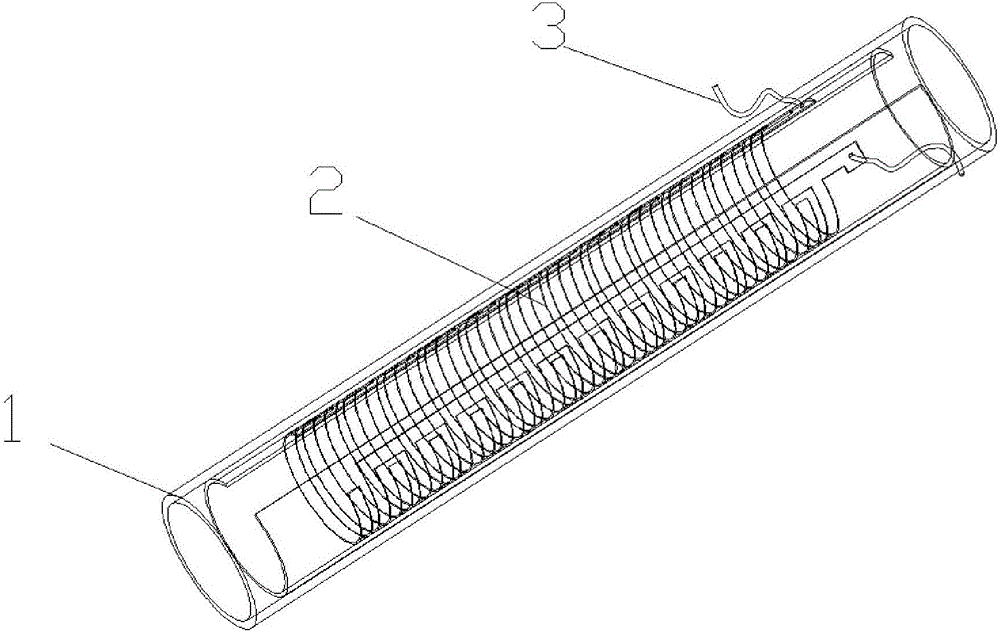

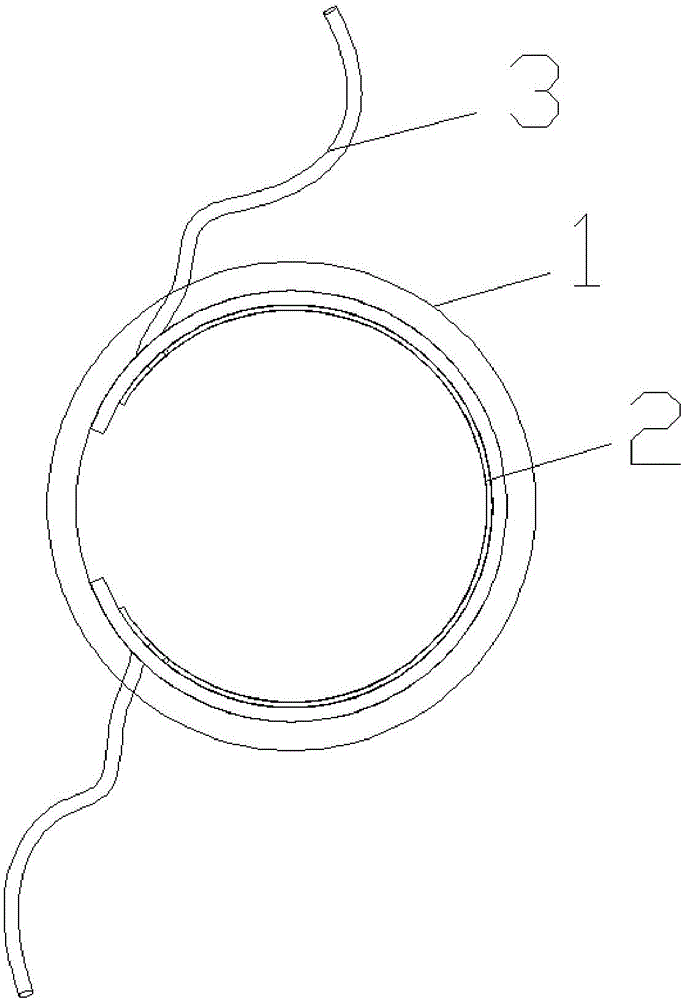

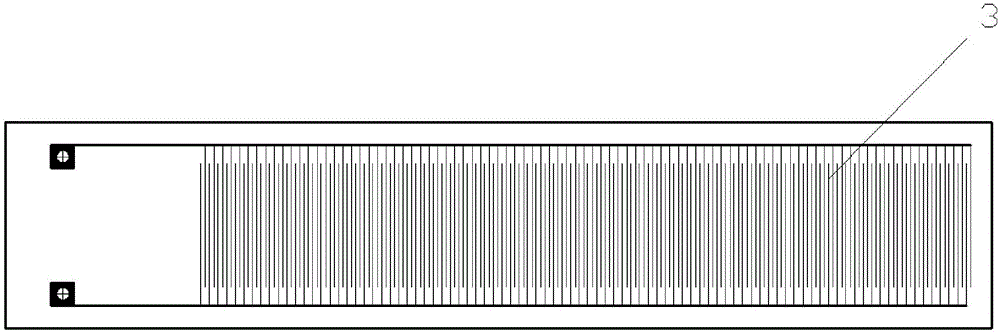

[0027] Such as Figures 1 to 3 shown. The invention discloses a cylindrical electrohydrodynamic micropump, which comprises a cylindrical pump casing 1 and an electrode array 2 arranged therein; the electrode array 2 includes mutually spaced cathodes and anodes, and the cathodes and anodes pass The electrode wire 3 welded thereon is connected with the power source outside the cylindrical pump casing 1 . The electrode array 2 (FPC) is manufactured by using a flexible circuit board as a substrate through a peeling process.

[0028] A cathode in the electrode array 2 and an anode adjacent thereto form a group of electrode pairs, and the cathodes and anodes are alternately arranged. The electrode wire 3 can be enameled wire, which has better corrosion resistance and insulation performance. The electrode array 2 is rolled into an elastic cylindrical structure, and closely adheres to the inner wall of the cylindrical pump casing 1 . The electrode array 2 is fixed axially and radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com