Combine harvester

A technology for combine harvesters and harvesting devices, which is applied to harvesters, agricultural machinery and implements, and threshing equipment, and can solve problems such as the reduction of grain stalk delivery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] First, the combine harvester 100 will be briefly described.

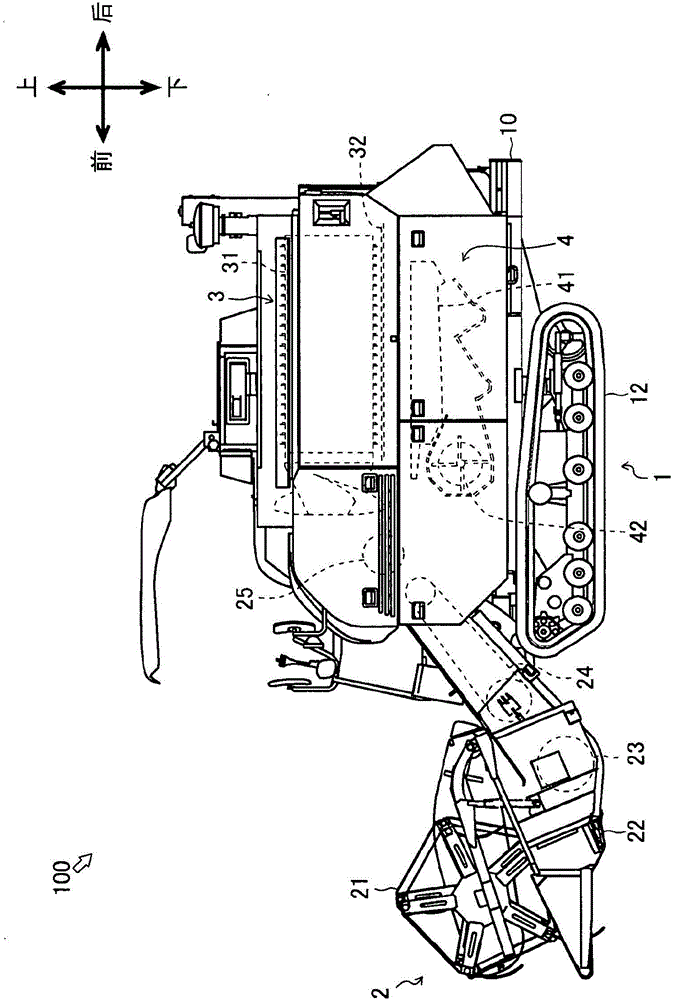

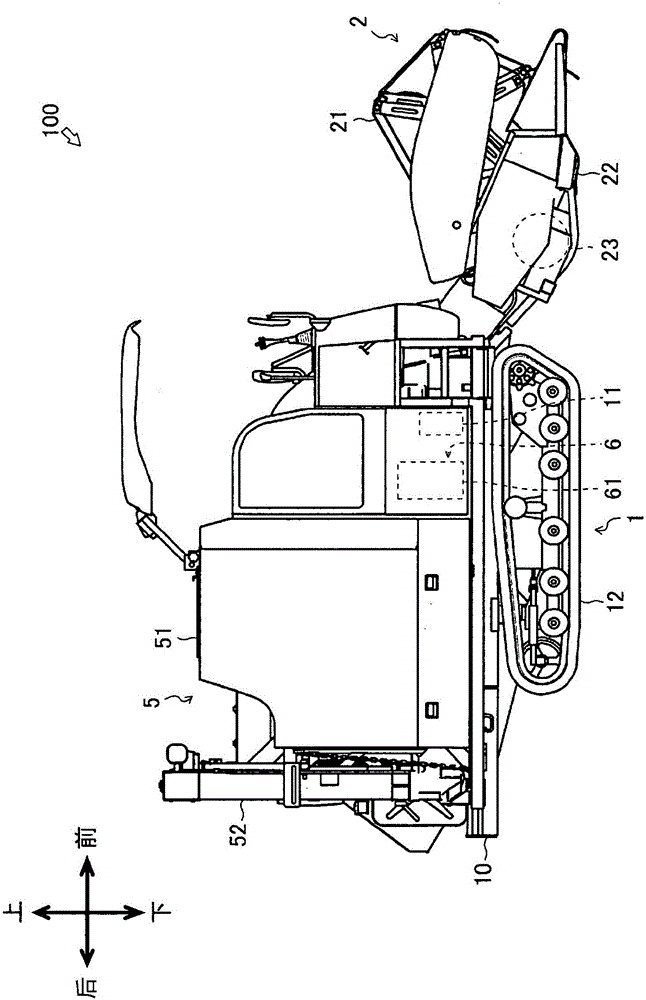

[0049] figure 1 The left side of the combine harvester 100 is shown. figure 2 The right side of the combine harvester 100 is shown. The figure shows the front-back direction and the up-down direction of the combine harvester 100.

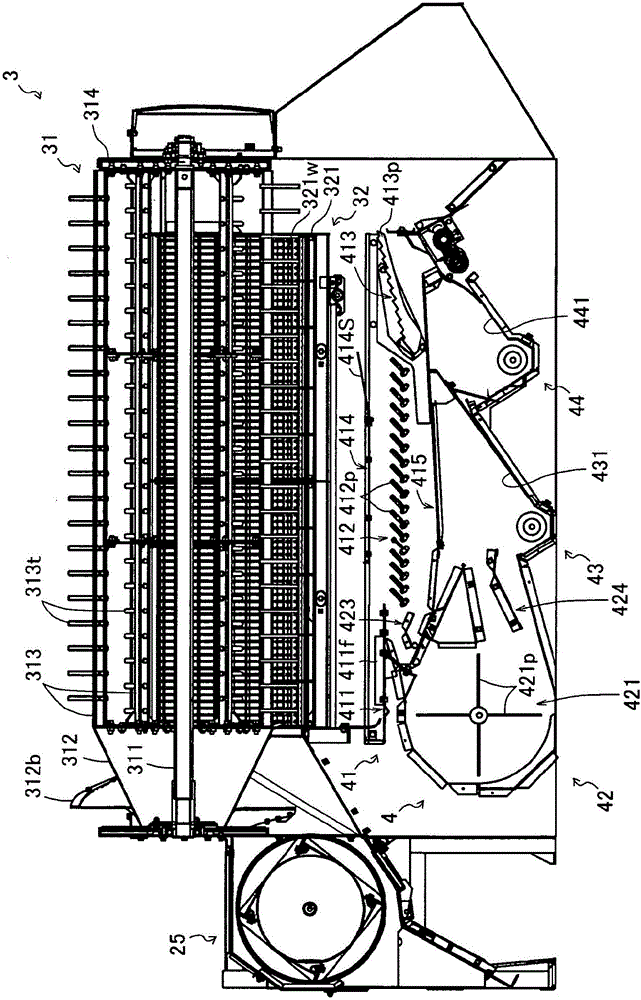

[0050] The combine harvester 100 is mainly composed of a traveling device 1 , a harvesting device 2 , a threshing device 3 , a sorting device 4 , a storage device 5 and a power device 6 .

[0051] The traveling device 1 is provided below the chassis frame 10 . The travel device 1 is composed of a transmission 11 and a pair of left and right crawler belt devices 12·12. The transmission 11 transmits power of a diesel engine 61 described later to the crawler belt devices 12·12. Crawler belt apparatus 12*12 runs the combine 100 in the front-back direction. Moreover, crawler belt apparatus 12*12 turns the combine 100 to the left-right direction.

[0052] Harvesting device 2 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com