Modular converter circuit having sub-modules, which are operated in linear operation

A converter and sub-module technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., can solve the problem of low power, achieve simple manufacturing and operation, small loss, avoid The effect of harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

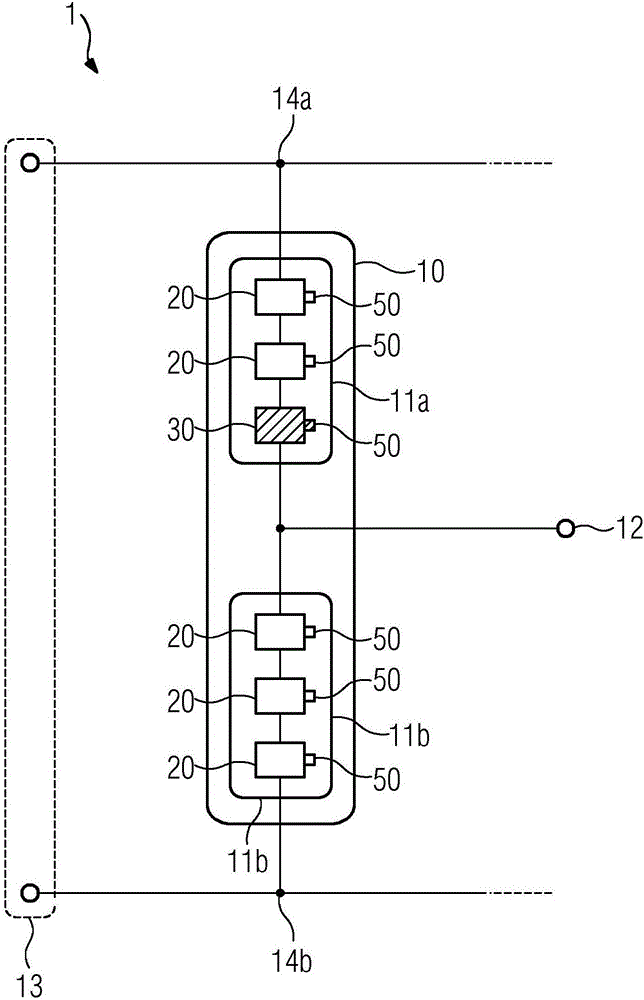

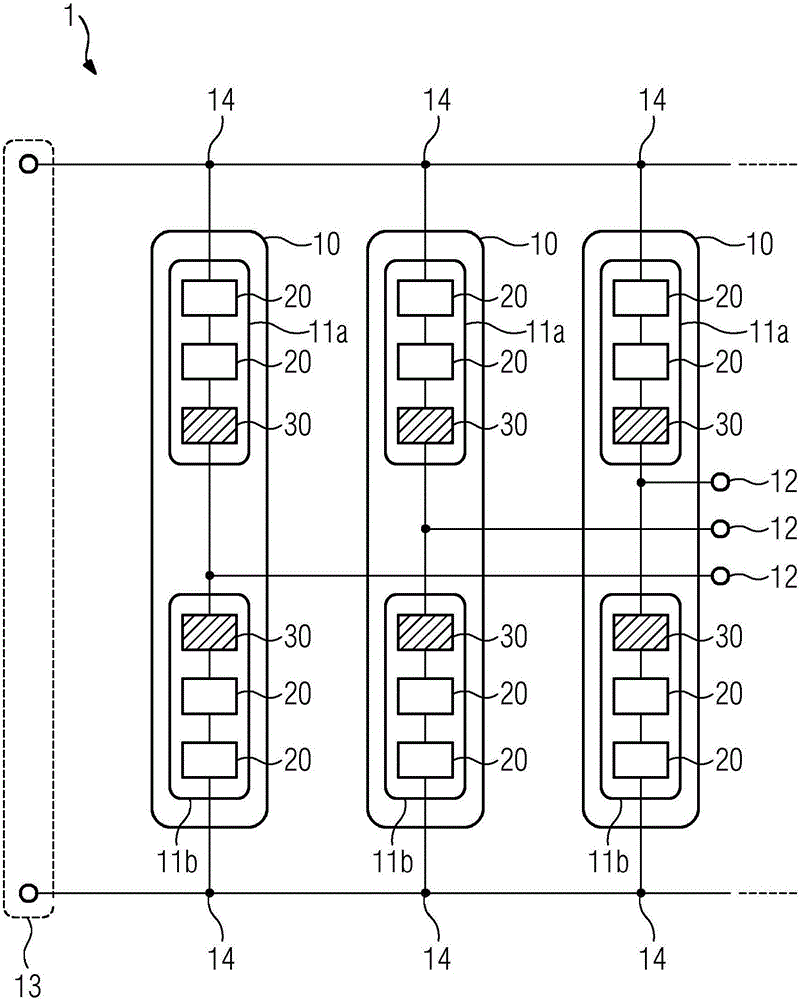

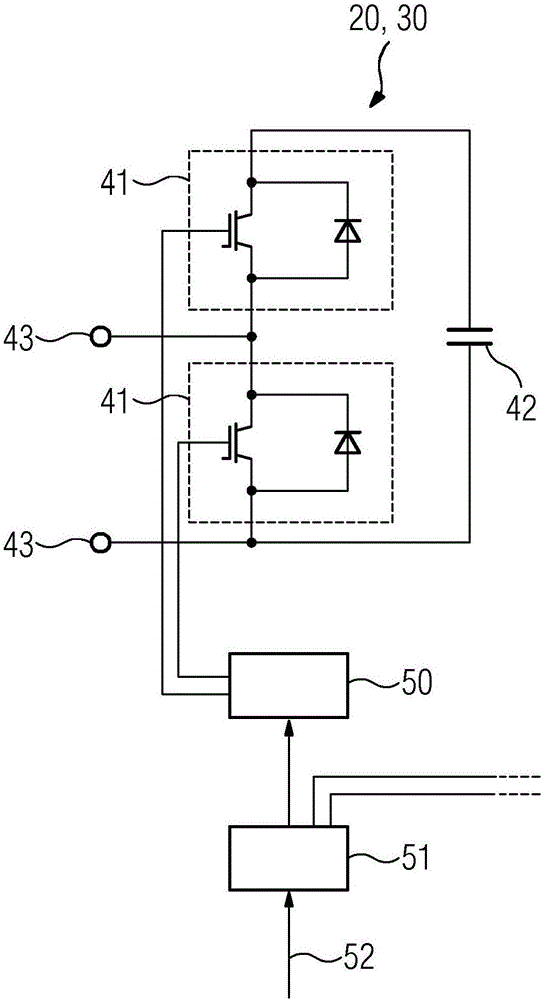

[0039] figure 1 An embodiment of an inverter circuit 1 according to the invention is shown. It has a DC voltage connection 13 . Thereby, the phase module 10 is connected to its interfaces 14a, 14b. The phase module 10 comprises a series circuit of an upper converter valve 11a and a lower converter valve 11b. The connection point of the two converter valves 11a and 11b forms the connection 12 on the AC voltage side. The two converter valves 11a and 11b in turn have a series circuit of one submodule 20 , 30 each. Each such submodule is connected to a drive assembly, which is advantageously arranged near the submodules 20 , 30 or even inside the submodules 20 , 30 . In the embodiment shown, the upper converter valve has a sub-module 30 suitable for linear operation. It is actuated via its actuating assembly 50 in such a way that a voltage with a continuous time profile can be generated at the output on the alternating voltage side with respect to the reference potential. An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com