Zirconium-based amorphous alloy and preparation method thereof

A technology of zirconium-based amorphous alloy and amorphous alloy, which is applied in the field of metal alloys, can solve the problem of small amorphous size and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

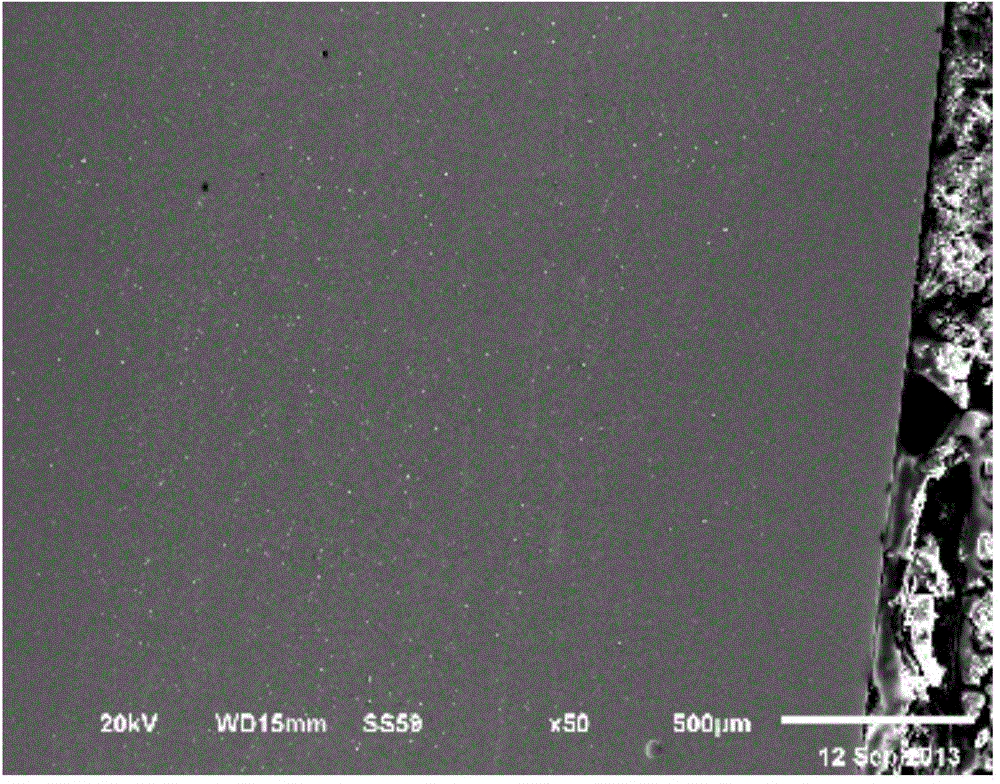

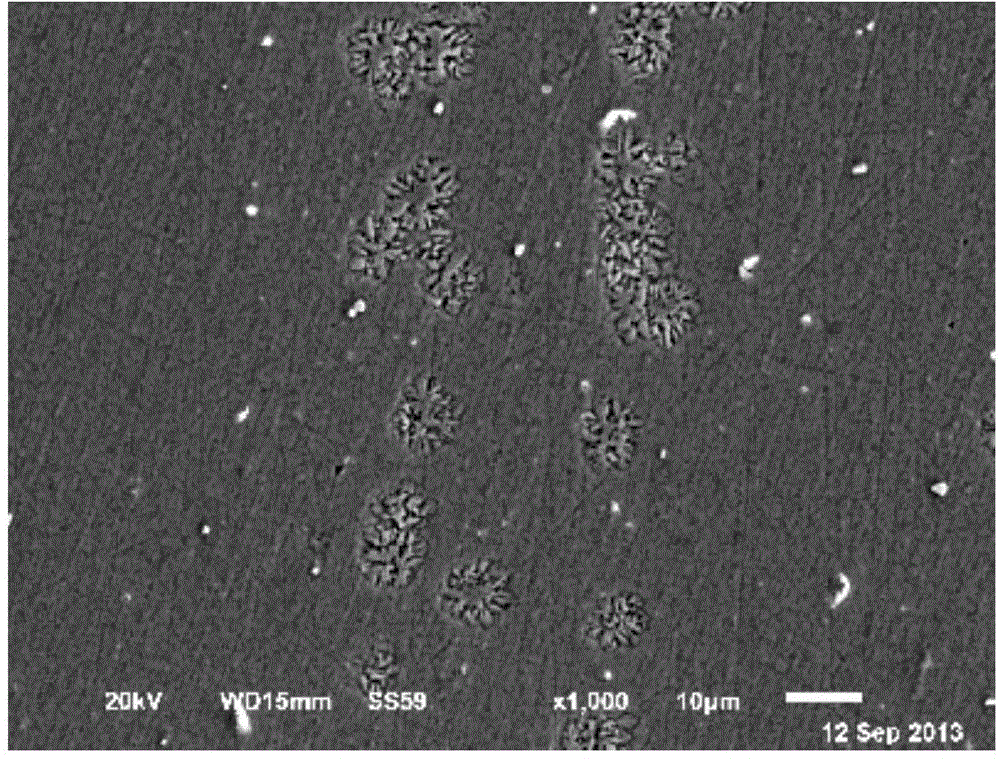

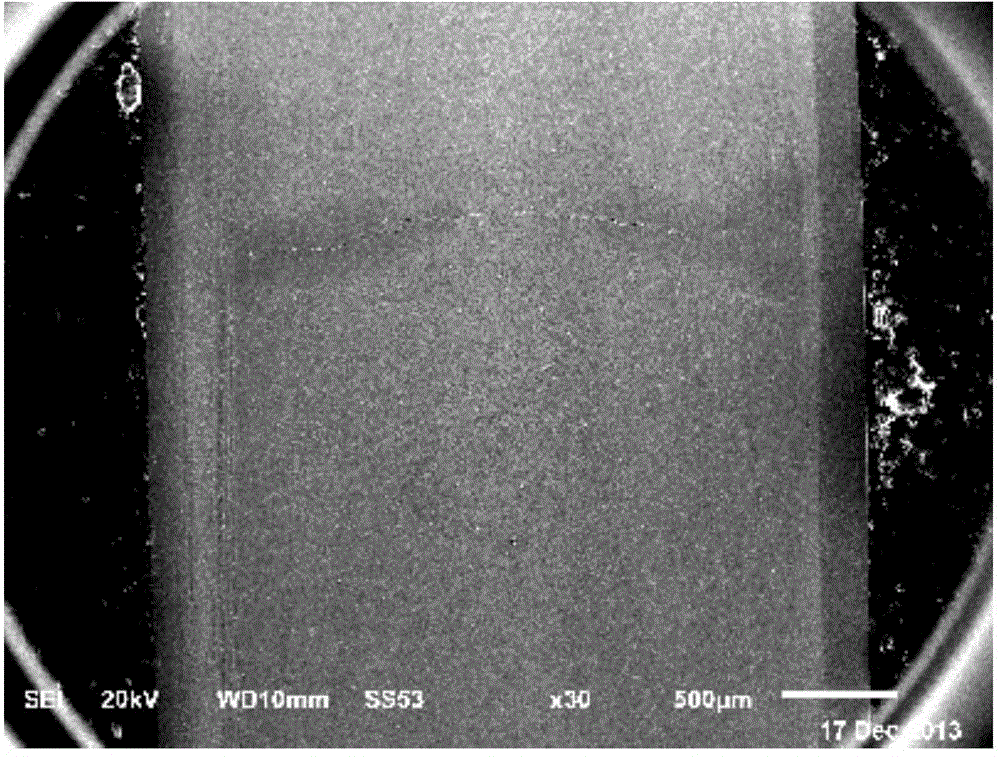

Image

Examples

preparation example Construction

[0021] The preparation method of the above-mentioned zirconium-based amorphous alloy specifically includes the following steps:

[0022] S1: Ingredients. Each composition is compounded according to a certain atomic percentage within the range of the above composition formula, for example, according to each composition and atomic percentage in Table 1. In the batching process, metal rods, blocks, ingots, plates and other materials with a purity greater than 99.9% of Zr, Cu, Al, Ni, Ti, Er, etc. can be alloyed according to the composition and atomic percentage in Table 1.

[0023] S2: Smelting. The prepared raw materials are put into the vacuum induction melting furnace. After vacuuming, the alloy raw materials are melted to completely melt, and stirred to make the ingredients evenly blended.

[0024] S3: cooling to form an amorphous alloy. The molten alloy material is cast into a metal mold for cooling treatment, so as to obtain a zirconium-based amorphous alloy ingot with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com