X-ray generating mechanism using electron field emission cathode

A field emission cathode and ray generation technology, applied in the direction of X-ray tube with huge current, X-ray tube, cathode ray convergence/focusing/guidance, etc., can solve the problem of X-ray beam non-uniformity, low current density, etc. problems, achieve high beam current, high control and focus, improved image quality and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Detailed description of the preferred embodiment

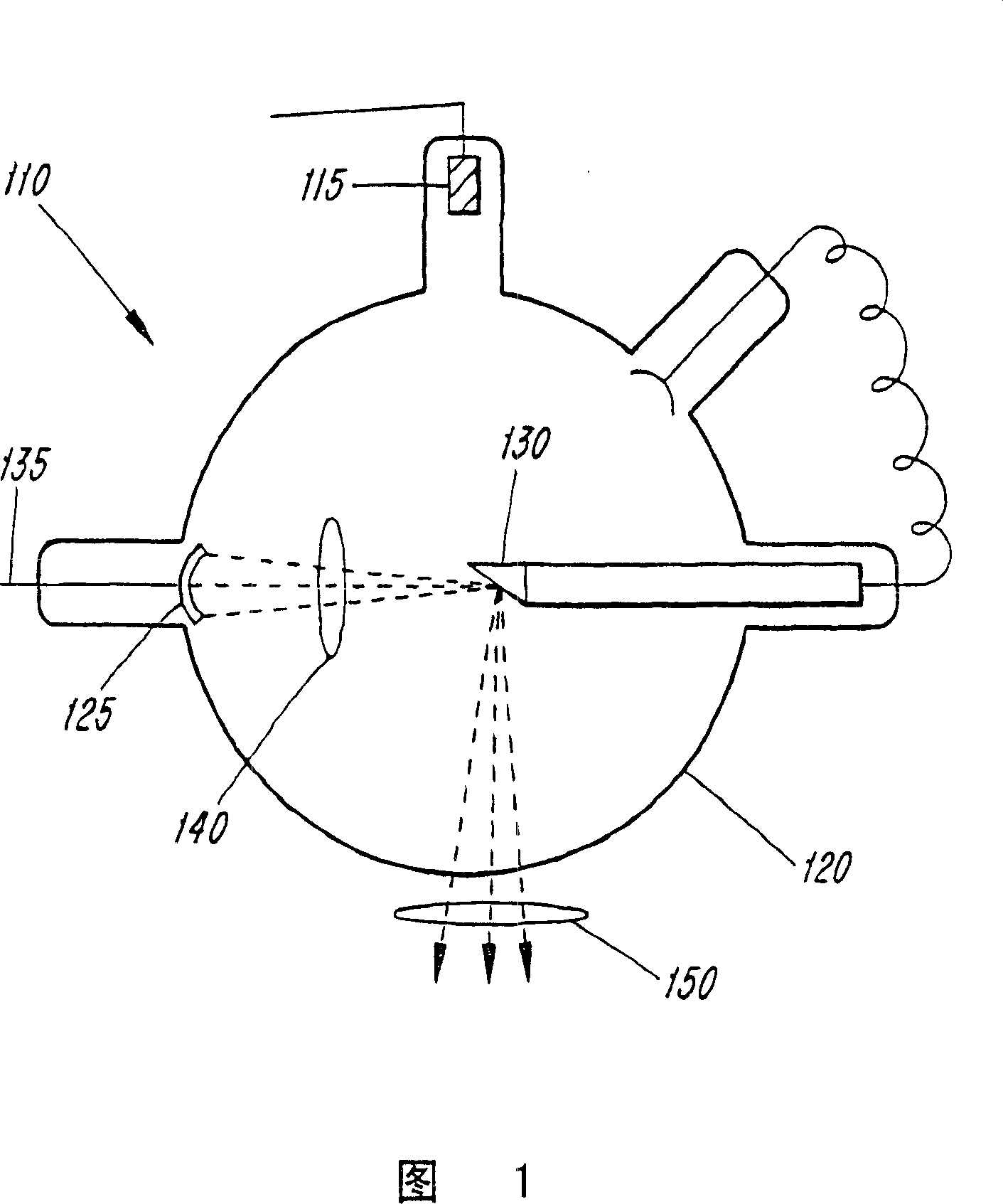

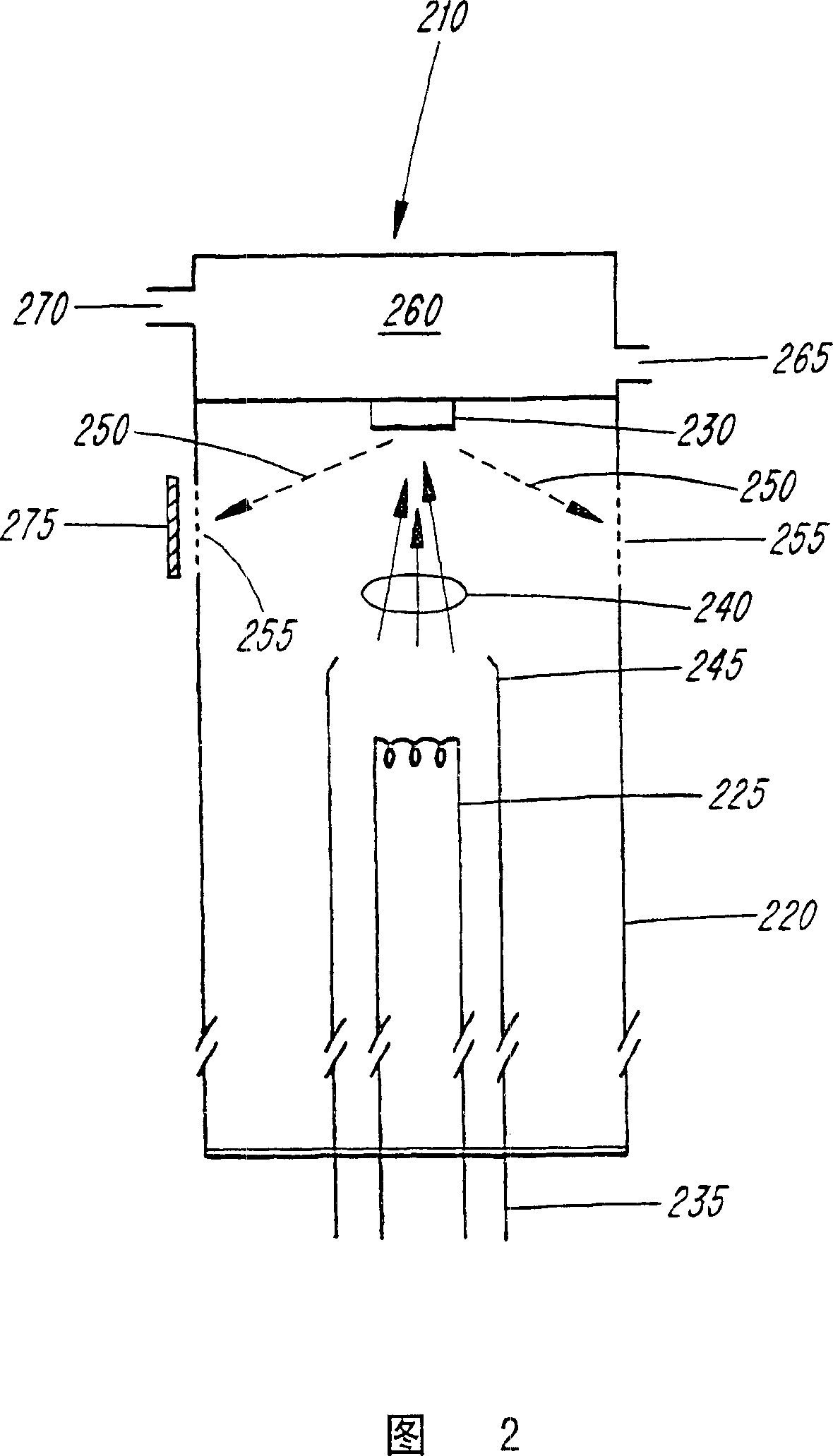

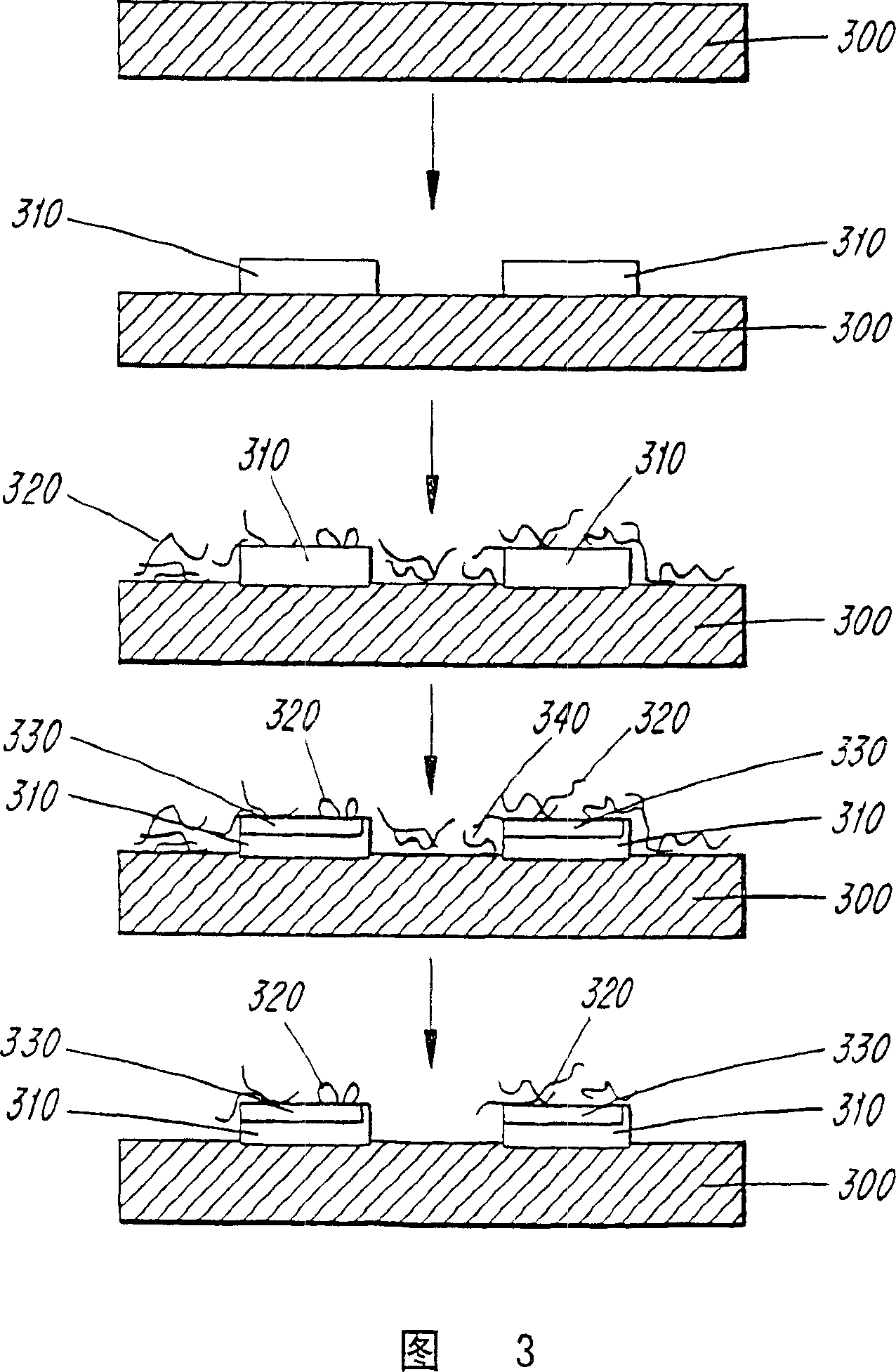

[0056] According to the invention, the cathode of the X-ray emitting device is formed at least partly by a material comprising nanostructures. Nanostructured materials have nanoscale dimensions. These nanostructures can have various shapes such as spheres, rods / wires or tubes.

[0057] The present invention contemplates the use of a variety of nanostructured materials with high emission current densities. For example, materials comprising silicon (Si), germanium (ge), aluminum (Al), silicon oxide, germanium oxide, silicon carbide, boron, boron nitride, and boron carbide are contemplated. The above materials are described in more detail, for example, in US Patent No. ____; (Serial No. 09 / 594,844, Attorney's Docket No. 032566-003), which is incorporated herein by reference in its entirety.

[0058] According to a further embodiment of the present invention, the material used to form at least a part of the cathode in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com