A mechanical arm mechanism of a lunar surface sampling device

A surface sampling and robotic arm technology, applied in manipulators, methods of obtaining raw materials from resources other than the earth, program-controlled manipulators, etc., can solve the problems of inability to know technical details, no mechanical arm design, etc., to achieve lightweight design, The effect of improving reliability and ensuring contact stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

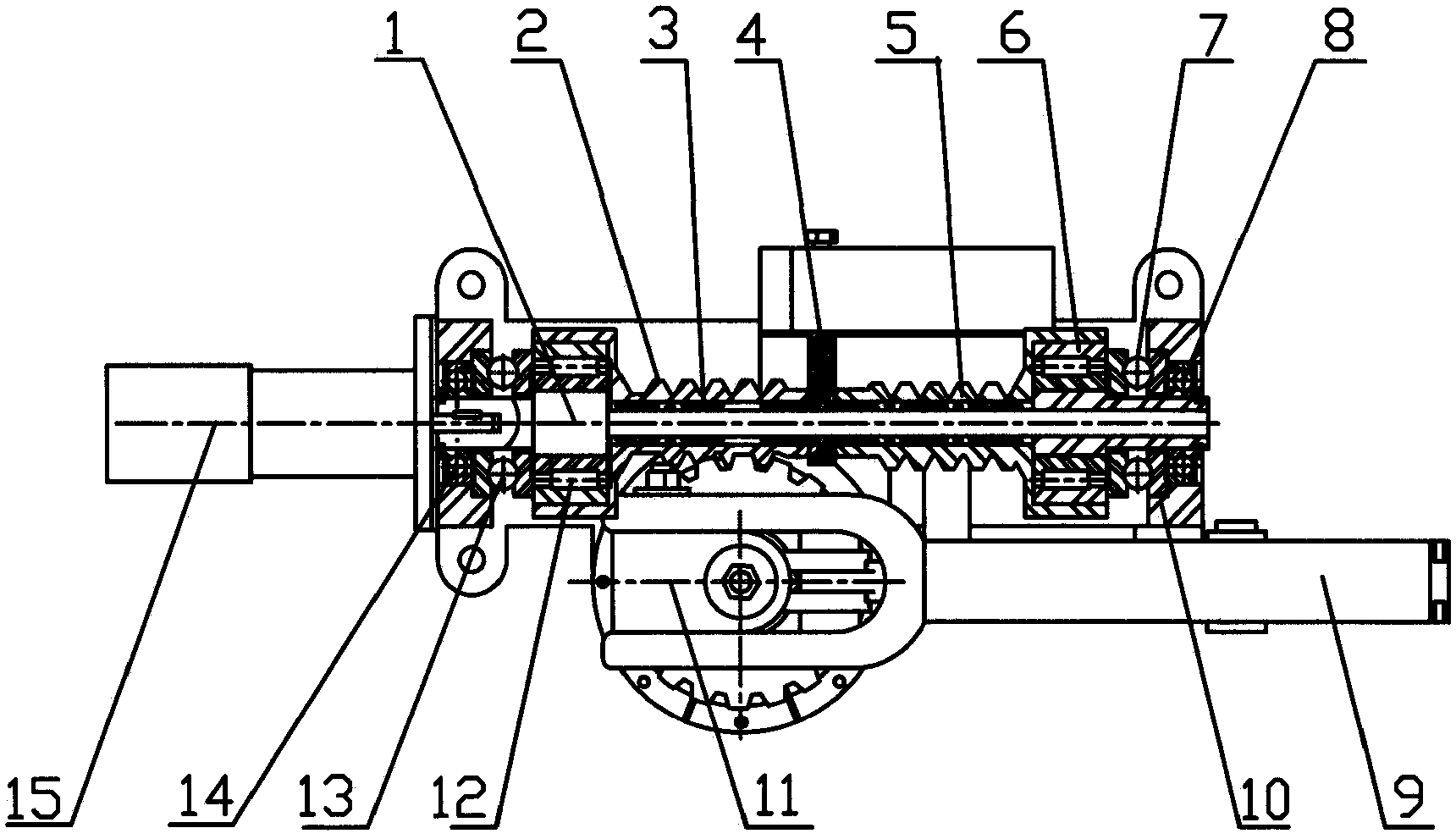

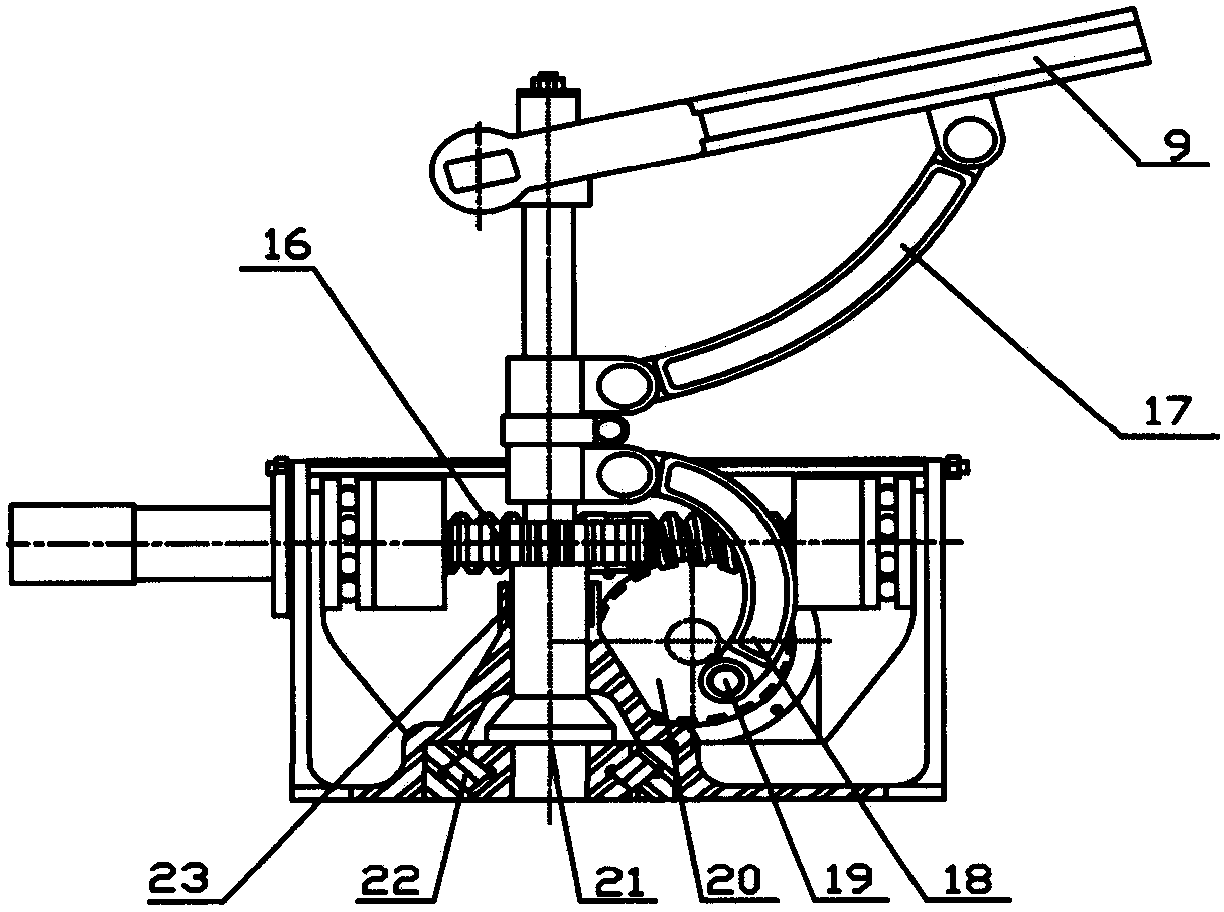

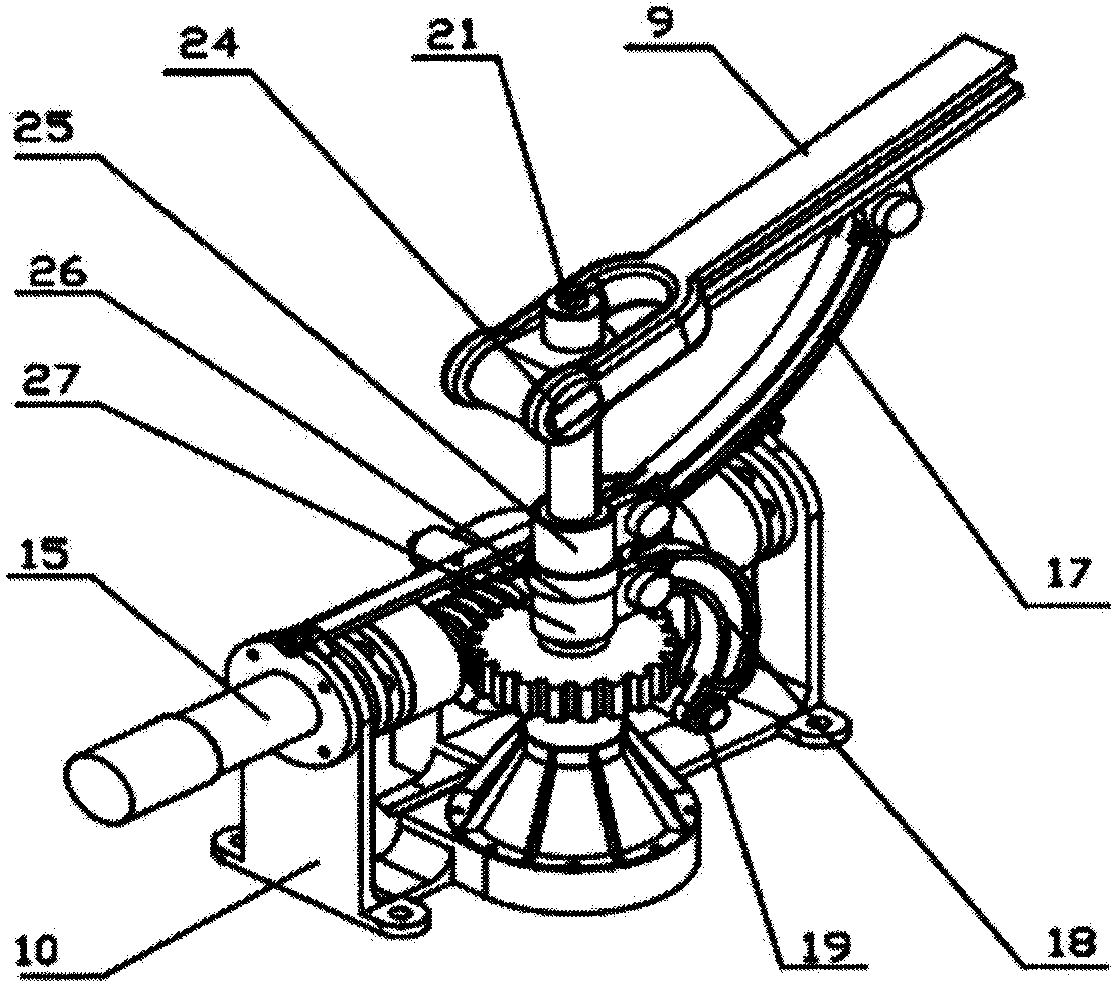

[0031] like figure 1 , 2 , Shown in 3, is the structural diagram of mechanical arm structure transmission shaft of the present invention. Transmission shaft 1 is fixed on the support 10 by radial bearing 8 and thrust bearing 7, and the left end of transmission shaft 1 is connected the rotating shaft of motor 15, and transmission shaft 1 is used as driving shaft, and left worm 2 and right worm 5 are installed on transmission shaft 1, The transmission shaft 1 supports the rotation of the left worm 2 and the right worm 5 through the needle roller 3, and the contact end of the left worm 2 and the right worm 5 bears the axial load and radial support through the support plate 4, and the non-rotation of the left worm 2 and the right worm 5 The contact ends are respectively fixed on the outer rings of the left one-way overrunning clutch 12 and the right one-way overrunning clutch 6 , and the inner rings of the left one-way overrunning clutch 12 and the right one-way overrunning clutc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com