A multi-output two-stage dc/dc converter using a composite pcb board transformer

A PCB board and converter technology, which is applied in the field of multi-output two-stage DC/DC converters, can solve the problem that the design method of multi-output power transformers is not described, does not involve power-on and power-off sequence control and failover, and cannot achieve multiple problems such as precise control of output converters, to achieve the effect of increasing power supply varieties, reducing volume and weight, and improving control functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

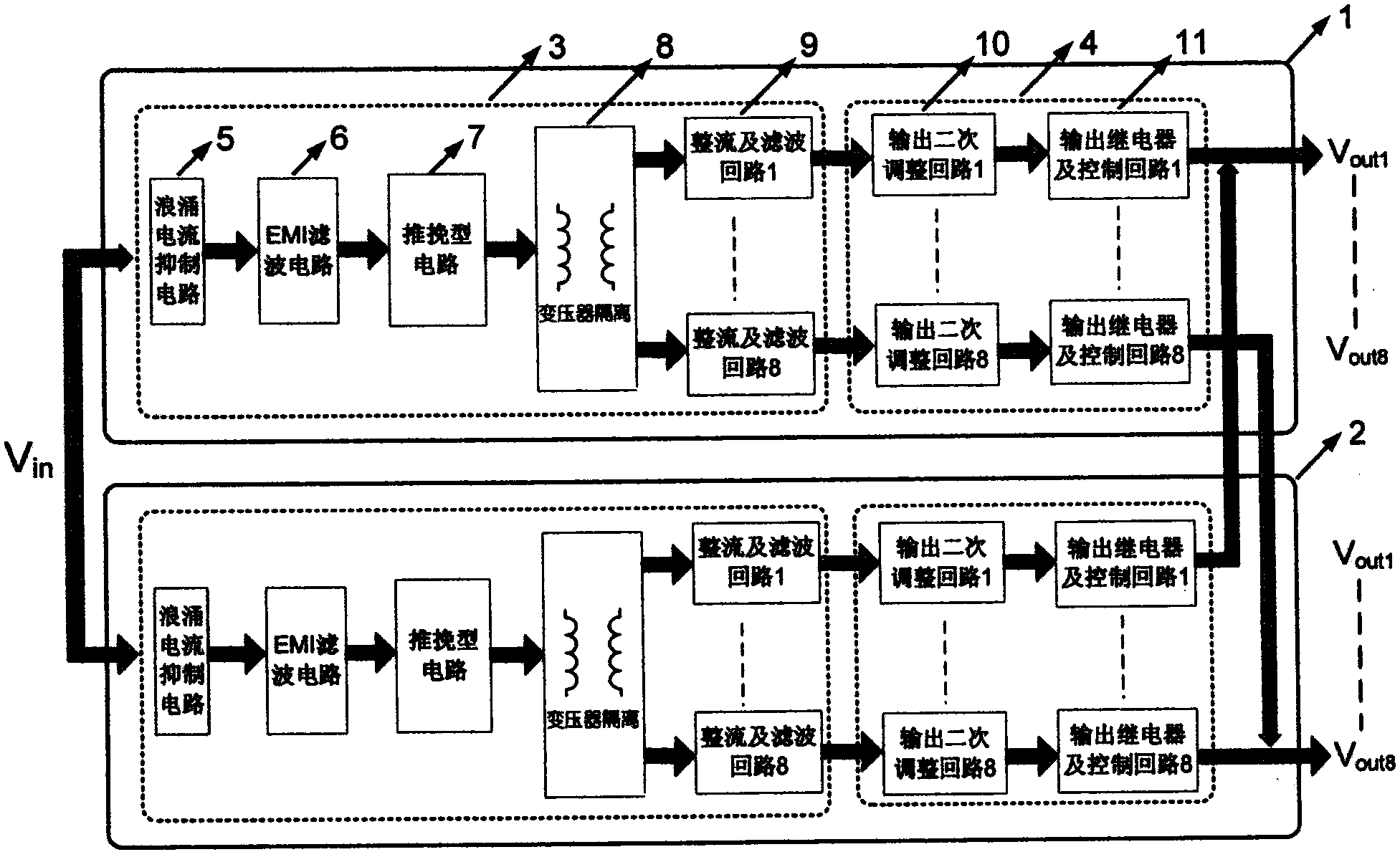

[0030] The circuit structure of the multi-output two-stage DC / DC converter of the present invention is as follows figure 1As shown, the multi-output two-stage DC / DC converter includes a redundant primary circuit 1 and a backup circuit 2, and the circuit structures and control methods are identical. Taking the master circuit 1 as an example, it includes a cascaded front-stage converter 3 and a rear-stage converter 4 .

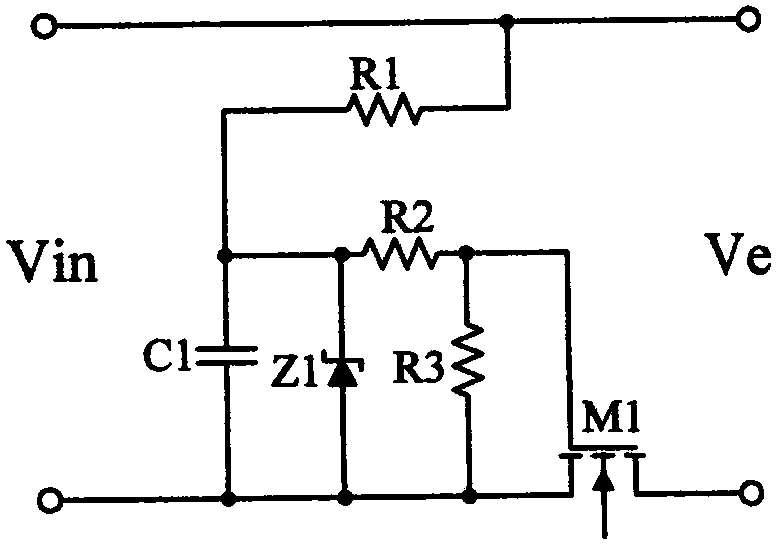

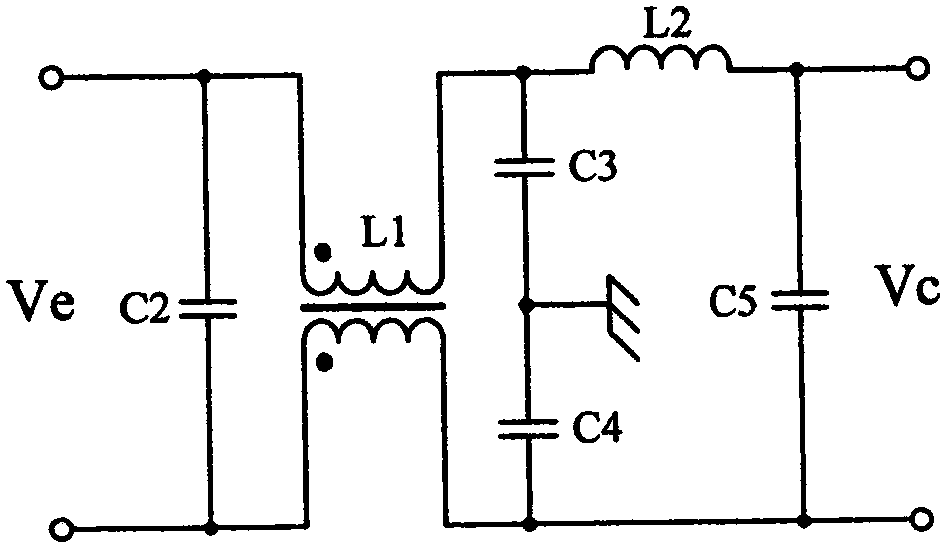

[0031] The pre-stage converter 3 converts the bus voltage into N output voltages through the push-pull circuit 7 and transformer isolation circuit 8 after being protected by the surge current suppression circuit 5 and filtered by the EMI input filter circuit 6, and each output voltage After smoothing and filtering by the rectification and filtering circuit 9, output to the rear-stage converter 4; each output secondary adjustment circuit in the rear-stage converter 4 receives the smooth-filtered voltage output by the previous stage, and adjusts the voltage accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com