Plate type spinning bed for silkworm cocoons

A plane and cocoon technology, applied in animal husbandry and other fields, can solve the problems of large footprint, small adjustment range, troublesome processing, etc., and achieve the effects of low maintenance cost, simple disassembly, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

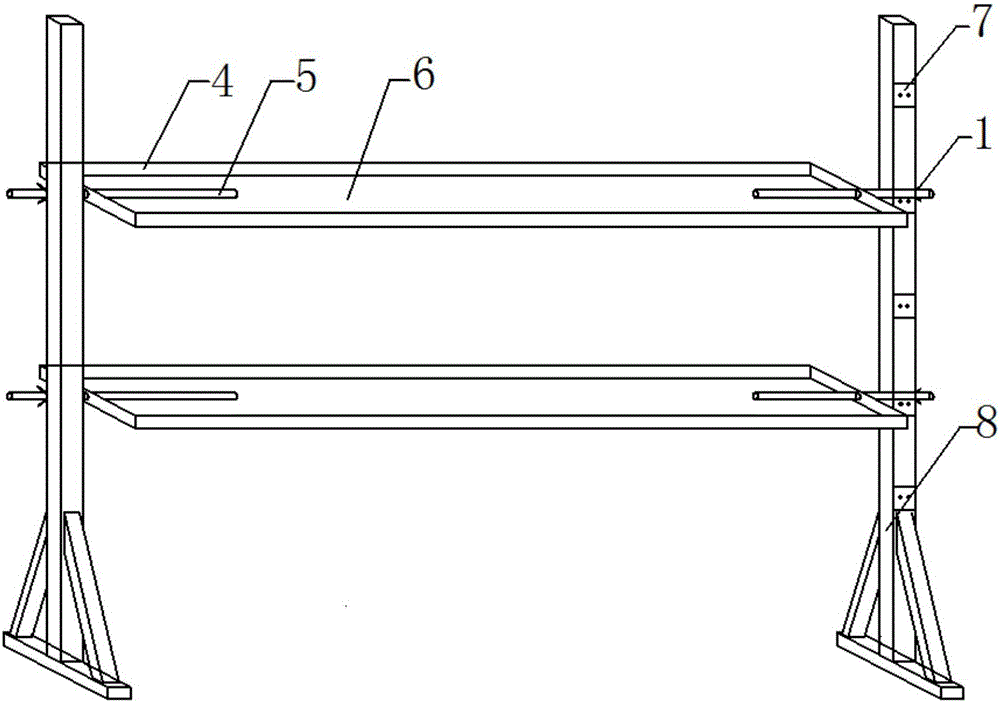

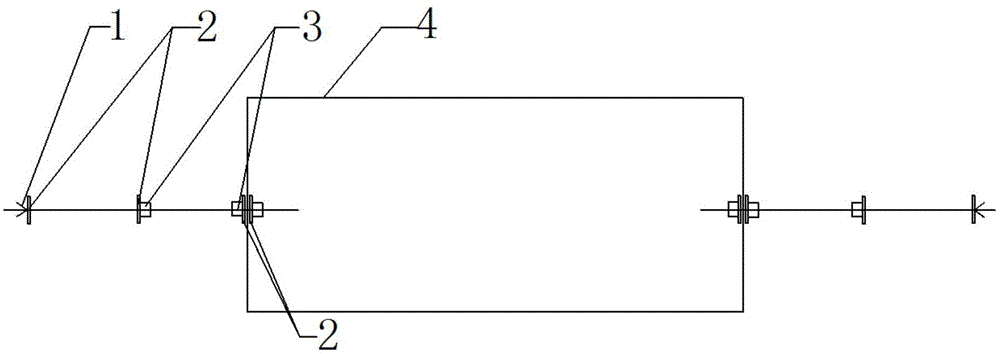

[0022] figure 1 It is the structure schematic diagram of the cocoon plane spinning bed of the present invention. A kind of silkworm cocoon plane spinning bed of the present invention comprises two independent supports 8, is provided with a plurality of spinning beds 6 on the support 8, and the adjustment range of the inclination of the spinning beds 6 is 0~360 °, can be according to each bed The actual situation requires single adjustment of the required angle of the spinning bed 6, so that the production efficiency is higher. During the silk spinning process, adjusting the spinning bed to be 30° from the horizontal plane is beneficial to silkworm cocoon spinning; when silkworm dung is found in the cocoon bed, adjusting the angle to 45° is beneficial to the sliding of silkworm dung; When the chrysalis tumbles down or when the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com