Mechanical powder scattering machine for frozen drink surface

A technology for frozen drinks and powder sprinklers, which is applied in the fields of frozen desserts, food science, and applications, can solve the problems of difficult and uneven patterning on the surface, and difficult to control the thickness quantitatively, so as to avoid powdered defective products and reduce Raw material loss and waste, the effect of increasing aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

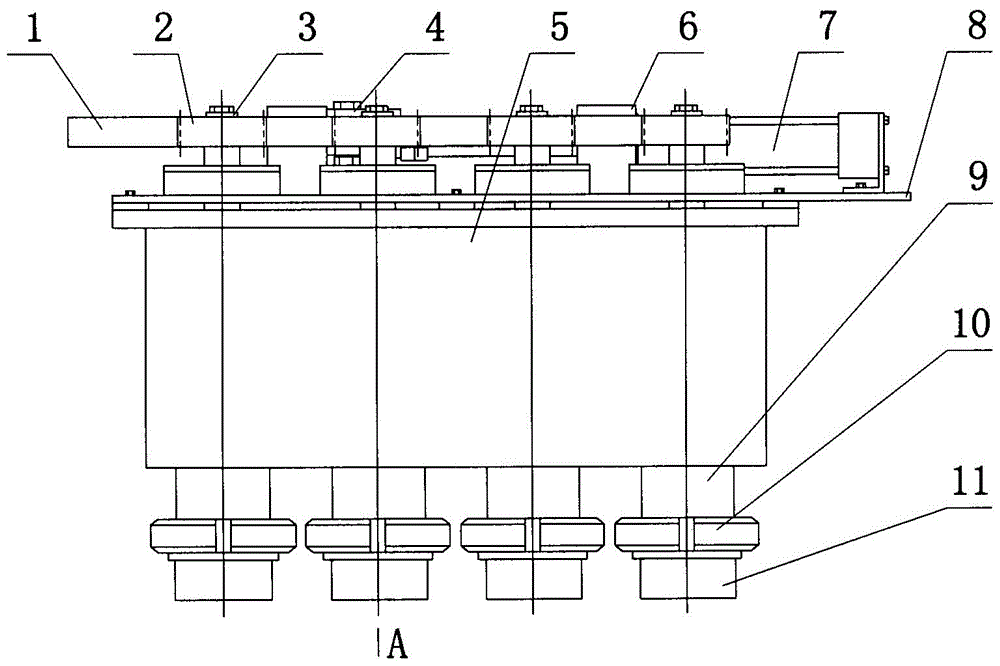

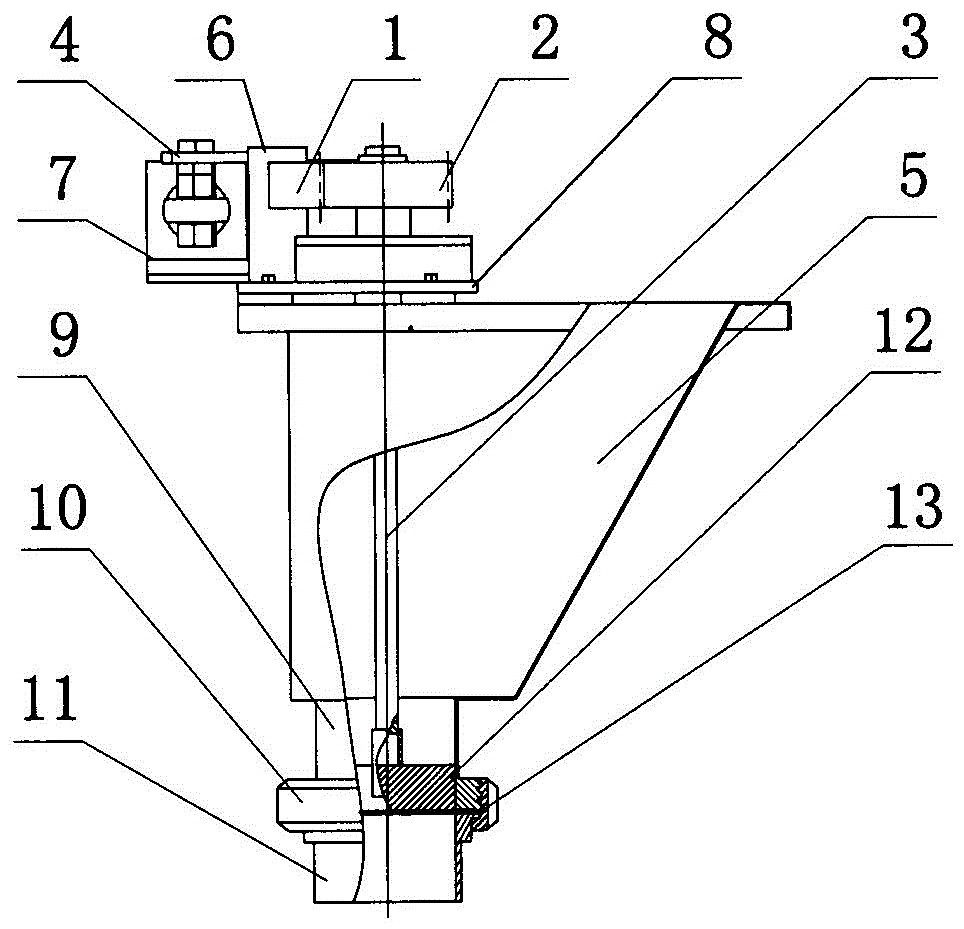

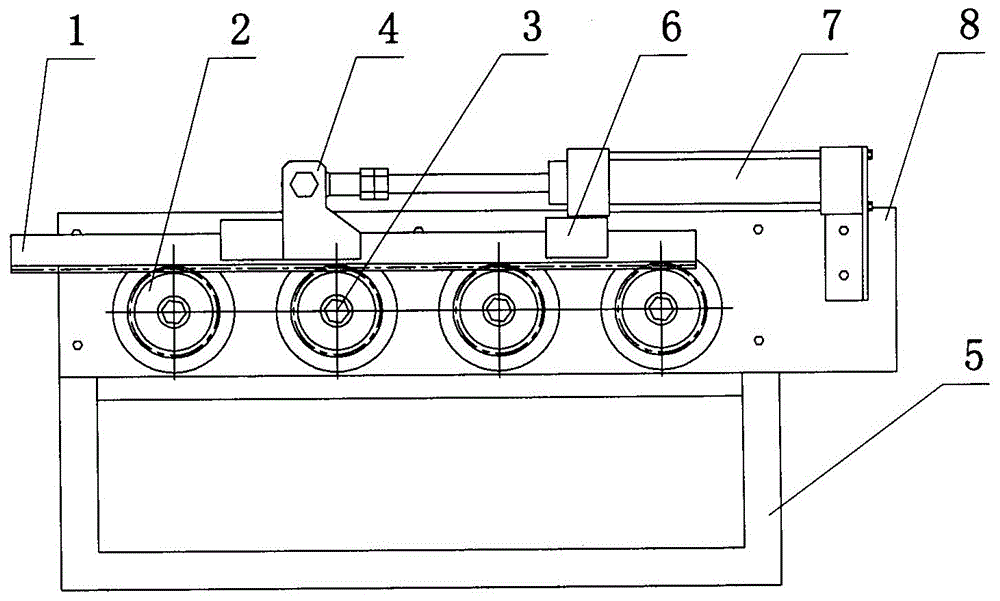

[0019] according to Figure 1~4 The specific structure of the present invention will be described in detail. The frozen drink surface mechanical duster includes a storage box 5, a fixed plate 8, a powder supply pipe 9, a powder duster 11 connected together, a power source 7 assembled on the fixed plate 8, and a reciprocating transmission mechanism. . Wherein the reciprocating transmission mechanism is made up of the gear 2 with the paddle shaft 3, the rack 1 moving along the chute of the guide slider 6 and the linkage seat 4 connected with the rack 1 and the power source 7, etc. The power source 7 can adopt a cylinder according to actual needs on the spot, and the linkage seat 4 is connected with the piston rod end of the cylinder. The power source 7 can also adopt a servo motor, and the linkage seat 4 is connected with the reciprocating drive rod end of the servo motor. The plectrum shaft 3 top of top fixed gear 2 is connected together with fixed plate 8 by bearing seat, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com