Patents

Literature

32results about How to "Avoid frequent contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

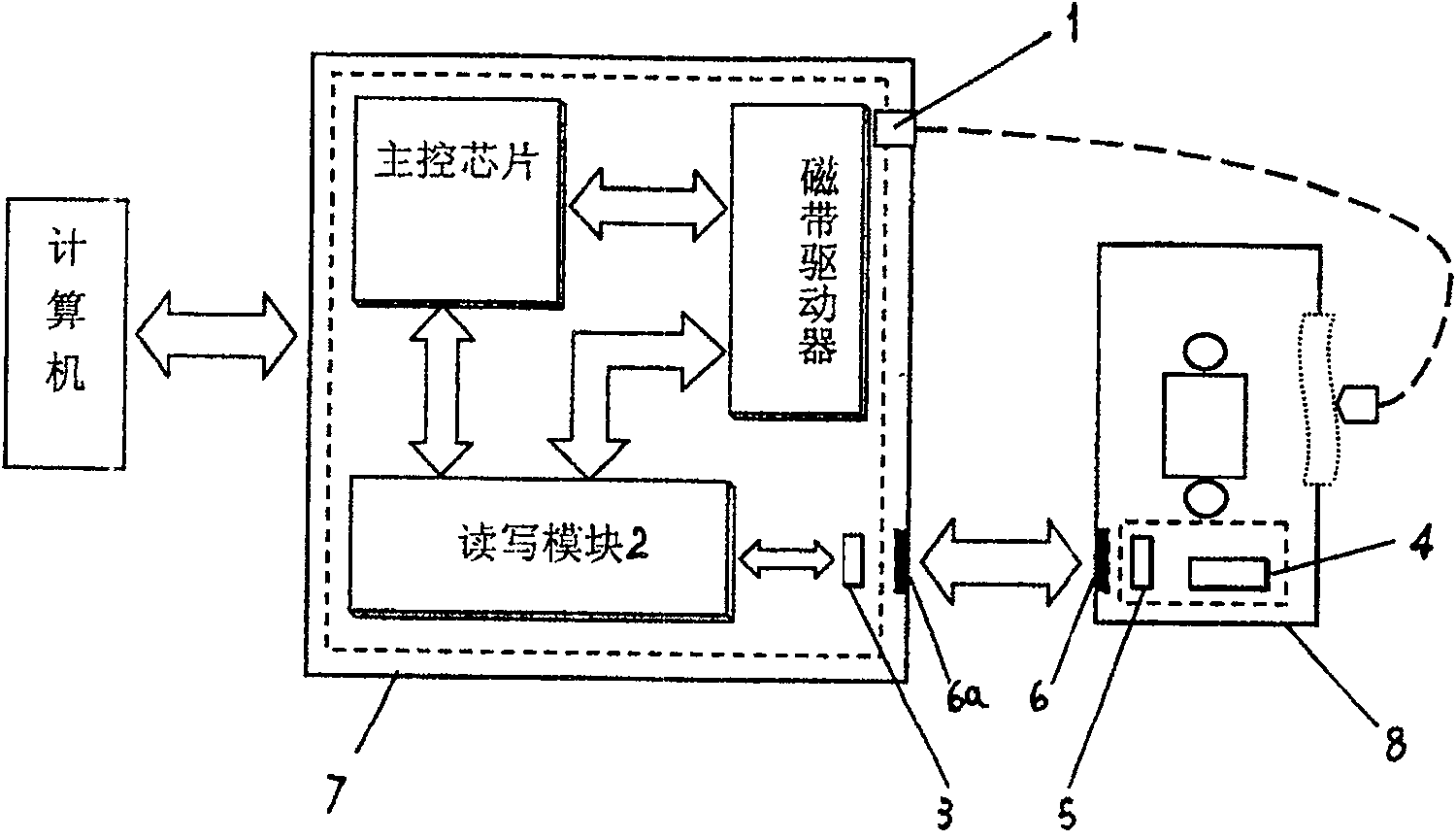

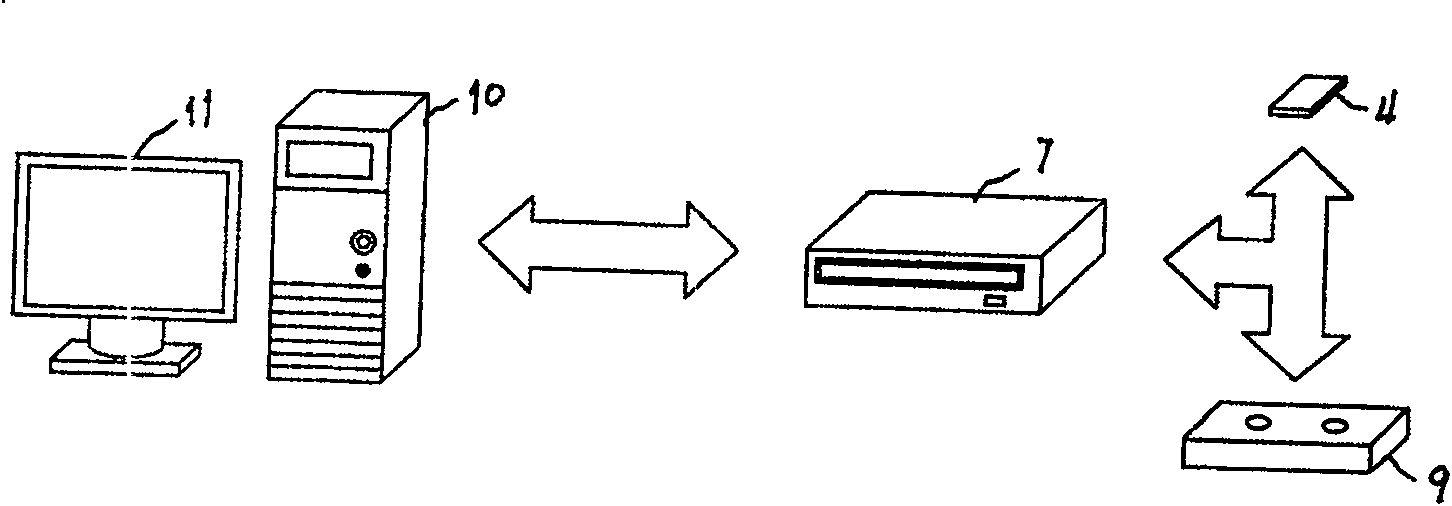

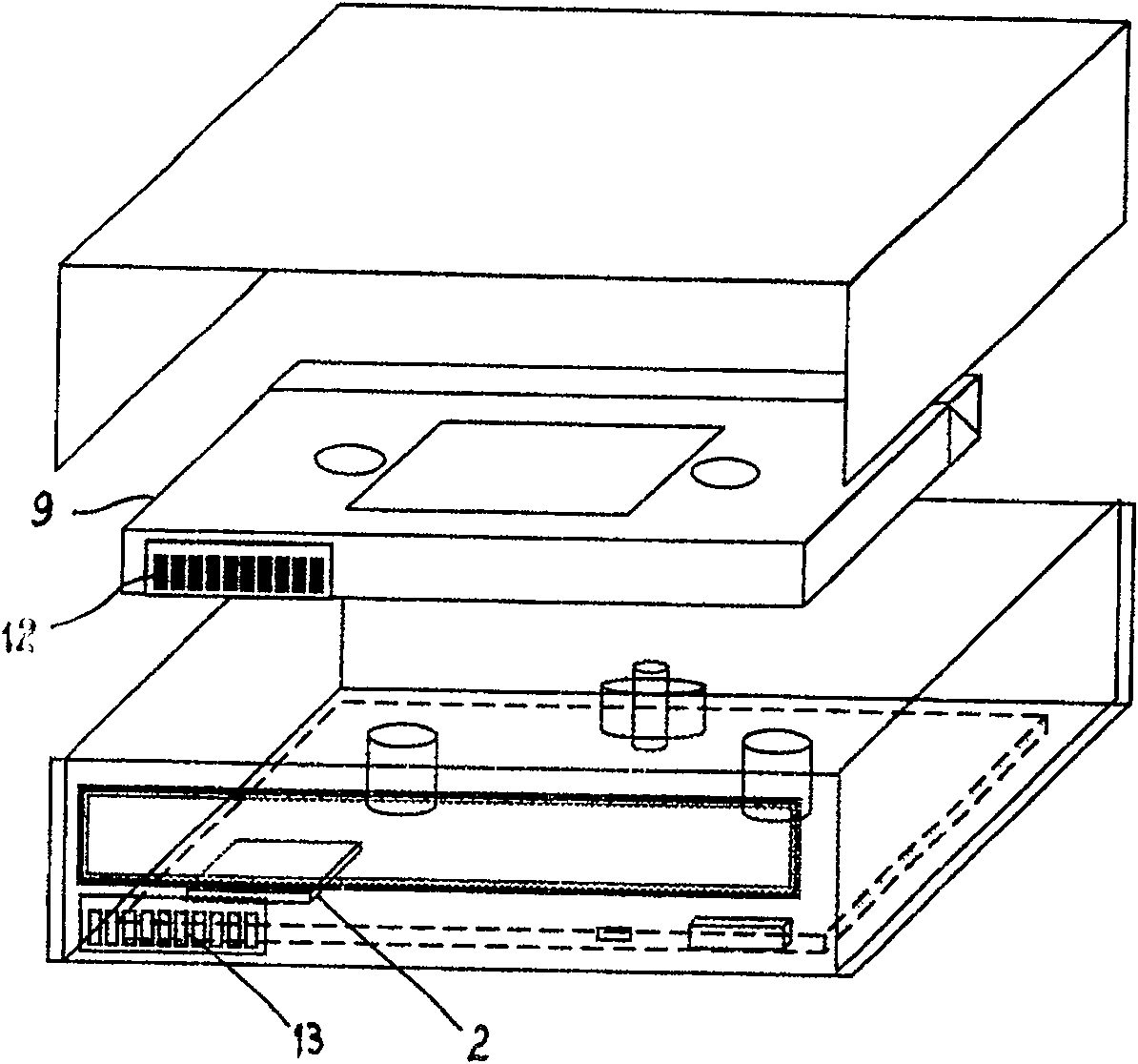

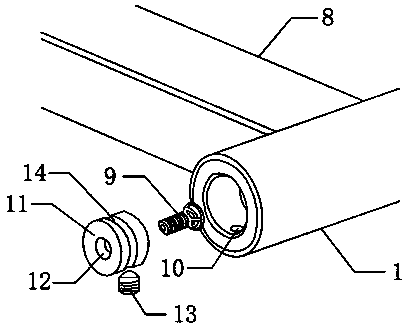

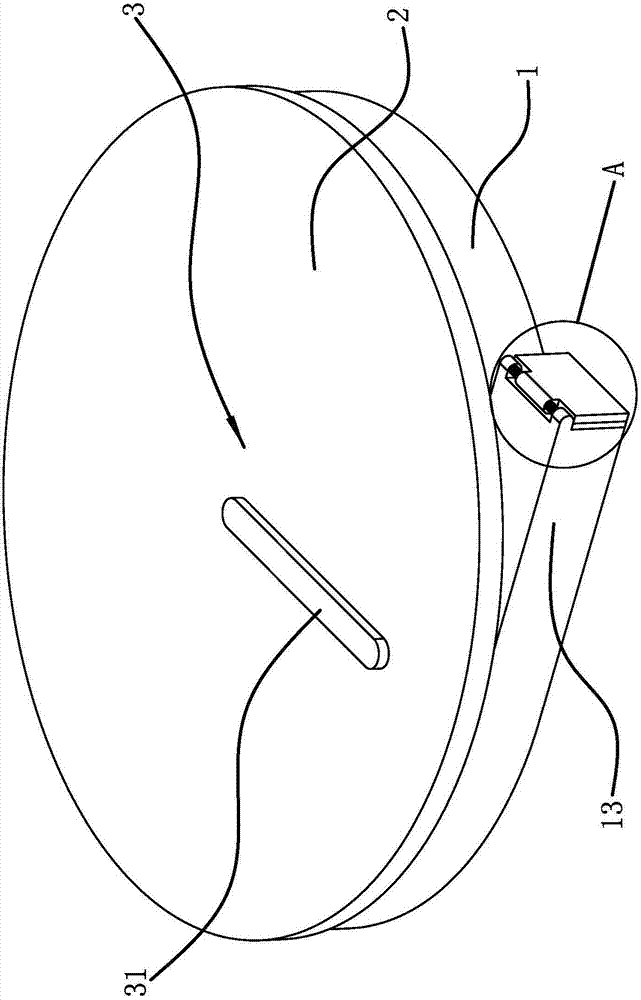

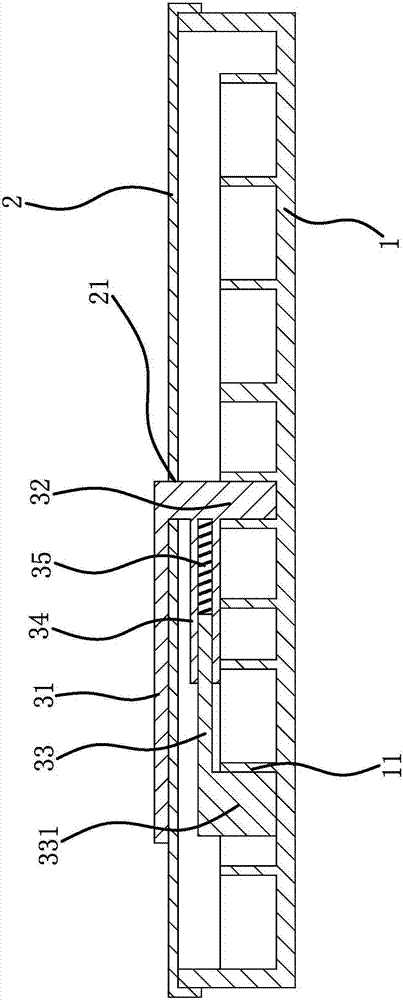

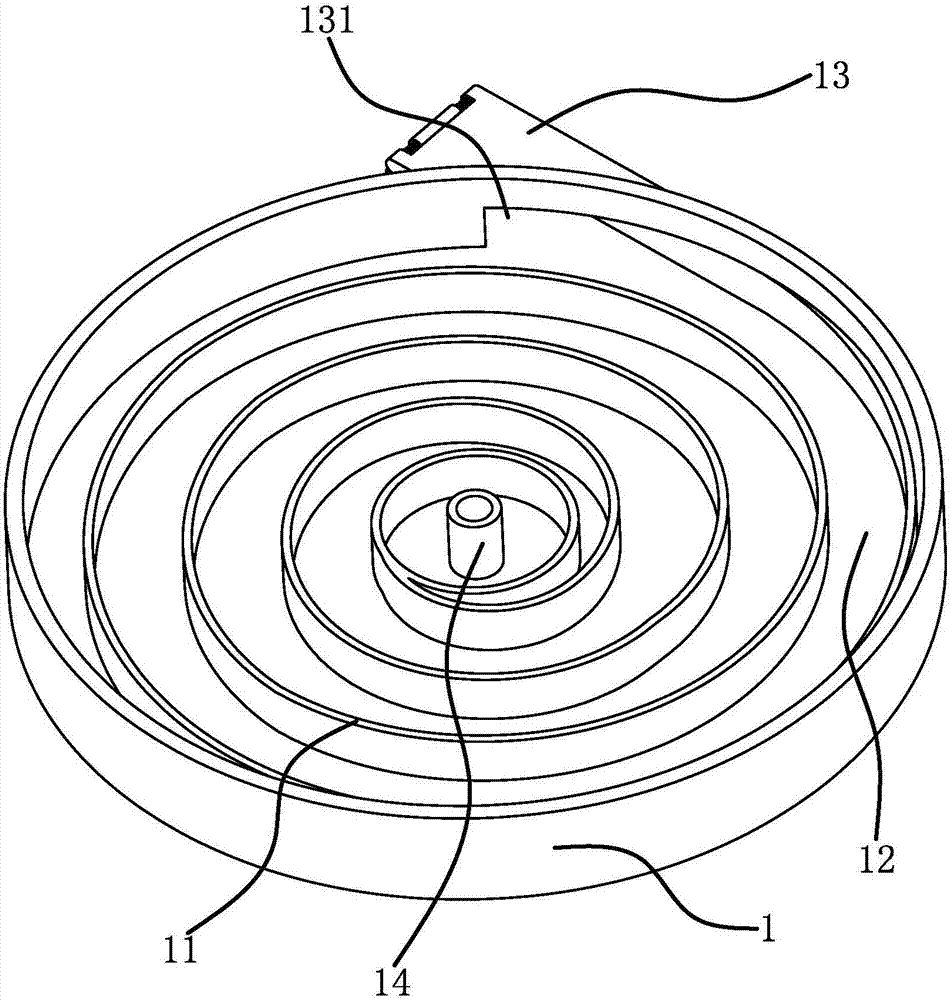

Novel intelligent tape unit and data processing method

InactiveCN101197177AReduce seek timeIncreased durabilityRecord information storageDigital storageMemory chipElectricity

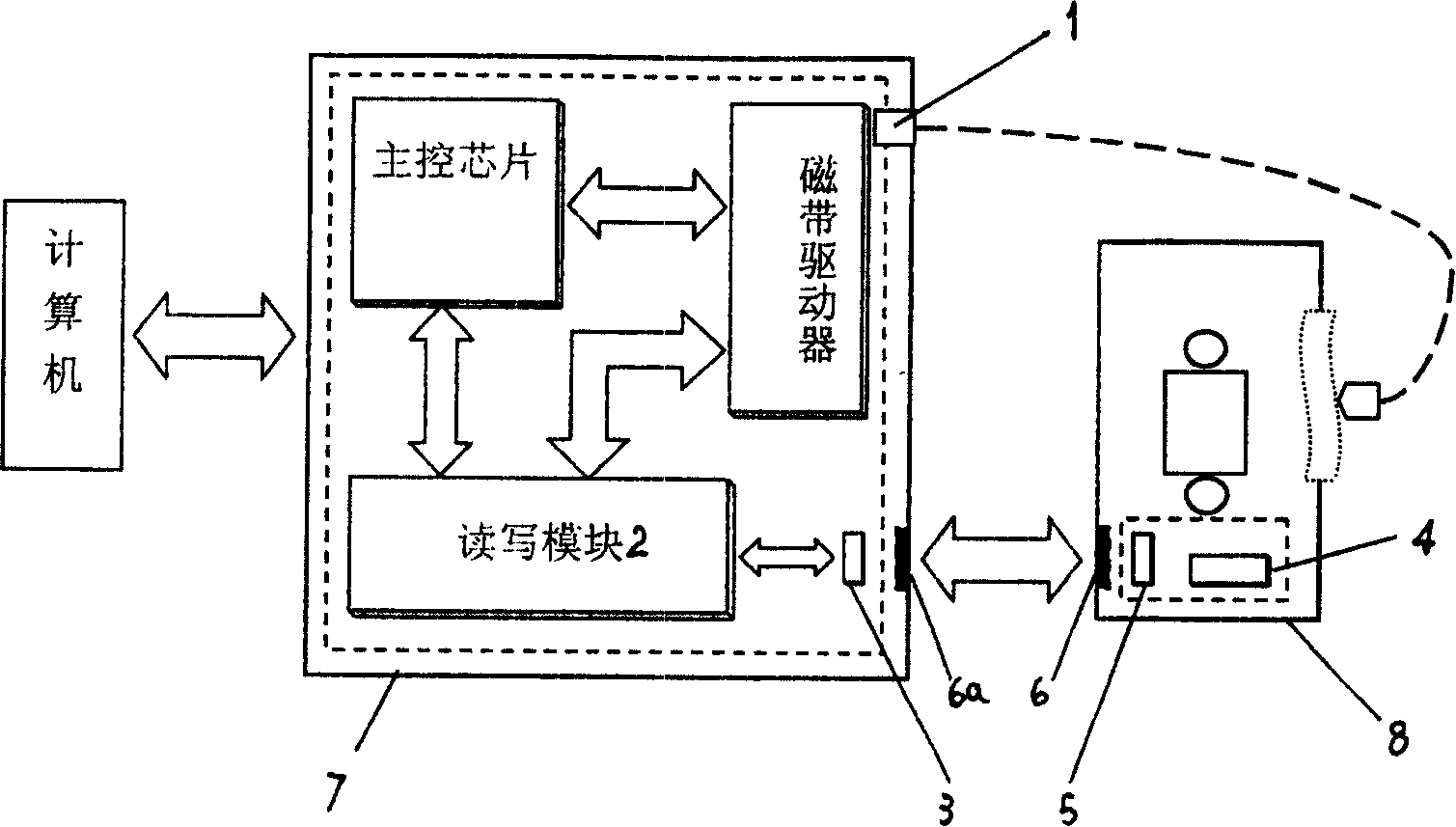

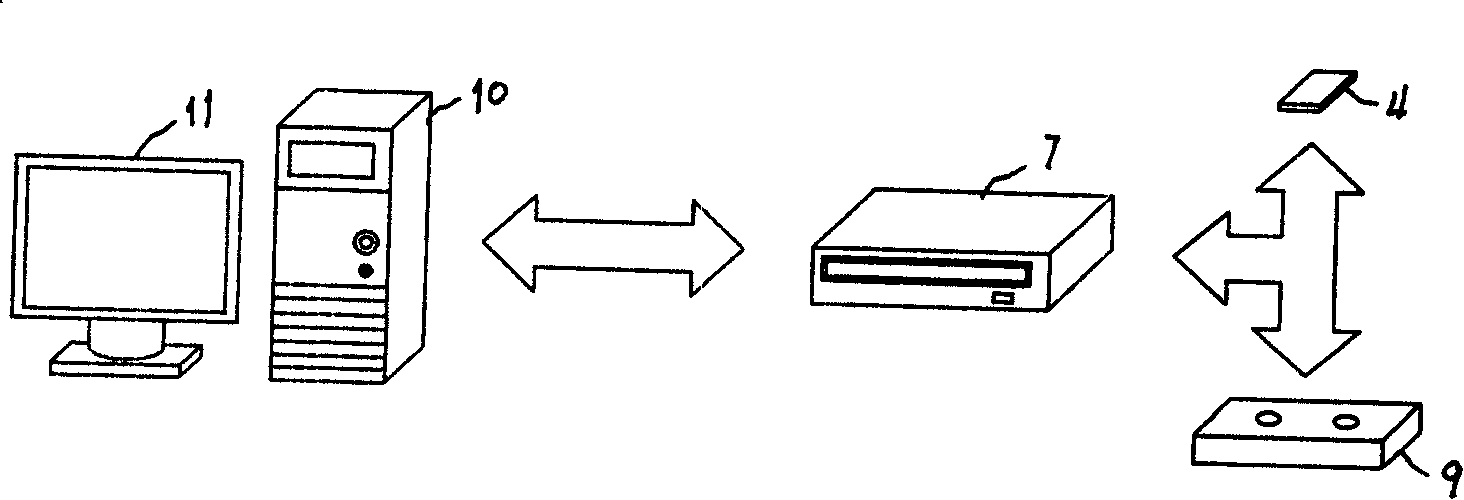

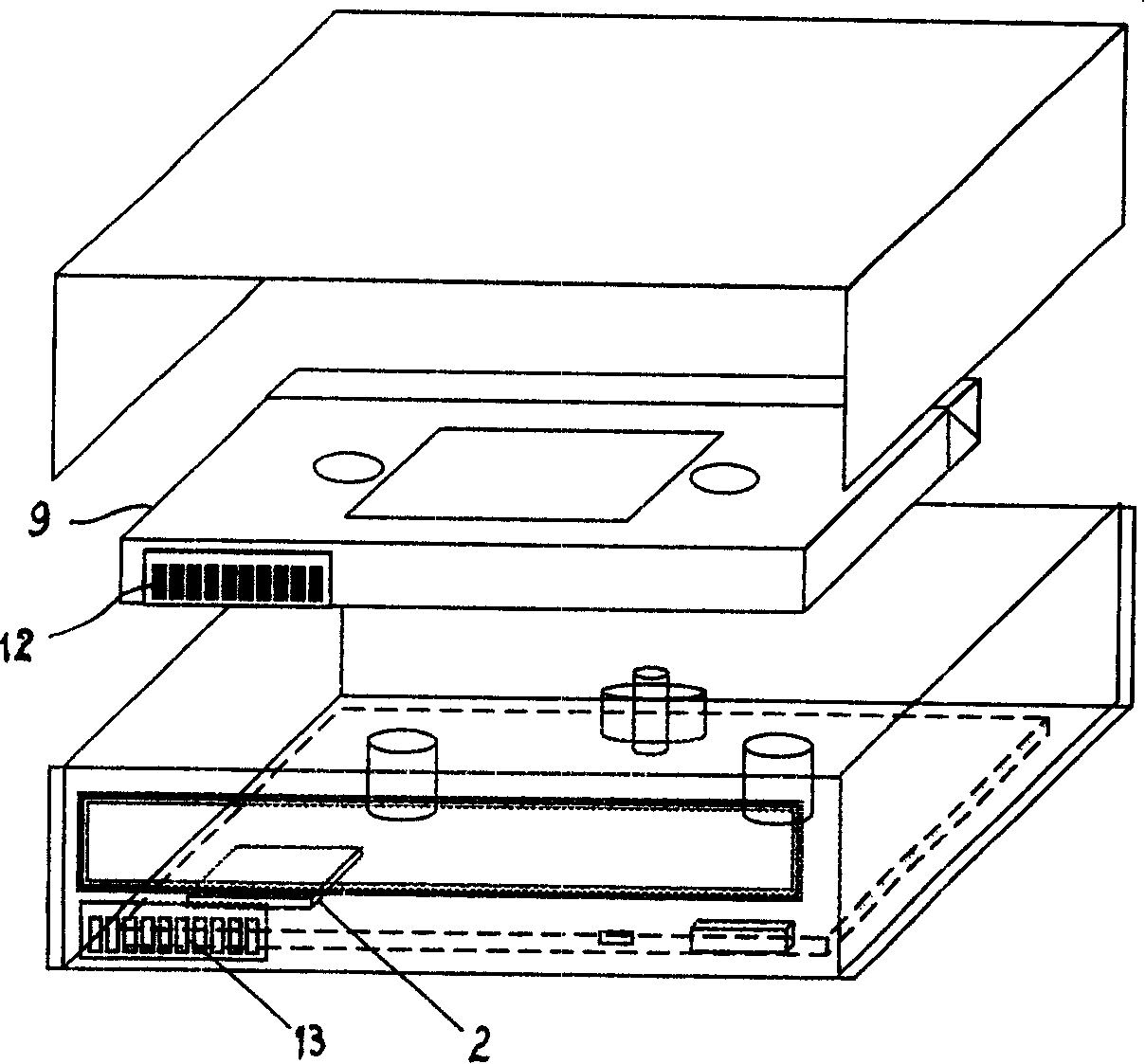

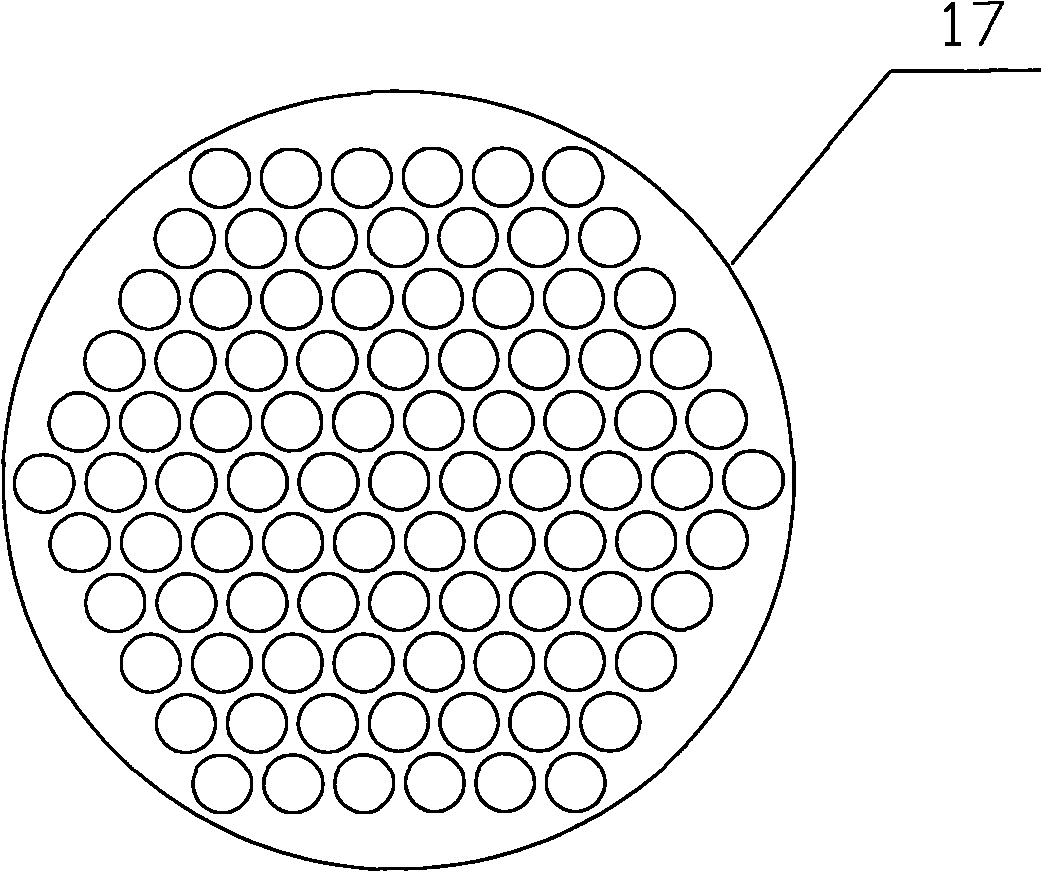

The invention discloses a novel intelligent tape driver and a data processing method thereof, belonging to a chip-tape storage device and a data processing method thereof, which comprises a memory chip arranged inside a tape cassette and an interface circuit thereof, and a memory chip read-write module arranged on the tape driver and an interface circuit thereof, wherein, the two interface circuits are electrically connected by a pair of metal contacts. The tape driver processor is connected with the memory chip through an interface circuit after being connected with the memory chip read-write module. Only a data area is arranged on the tape. The memory chip is divided into an index mark section, a writing cache, a read cache and other data section, wherein, both reading and writing requests of data are performed in the reading and writing caches, other than in the tape driver. The combination of the sequential memory of the tape and the random memory of the chip reduces the frequent mechanical motion of the tape driver, thereby improving the retrieval speed and the memory efficiency and prolonging the service life of the tape driver.

Owner:WISESOFT CO LTD +1

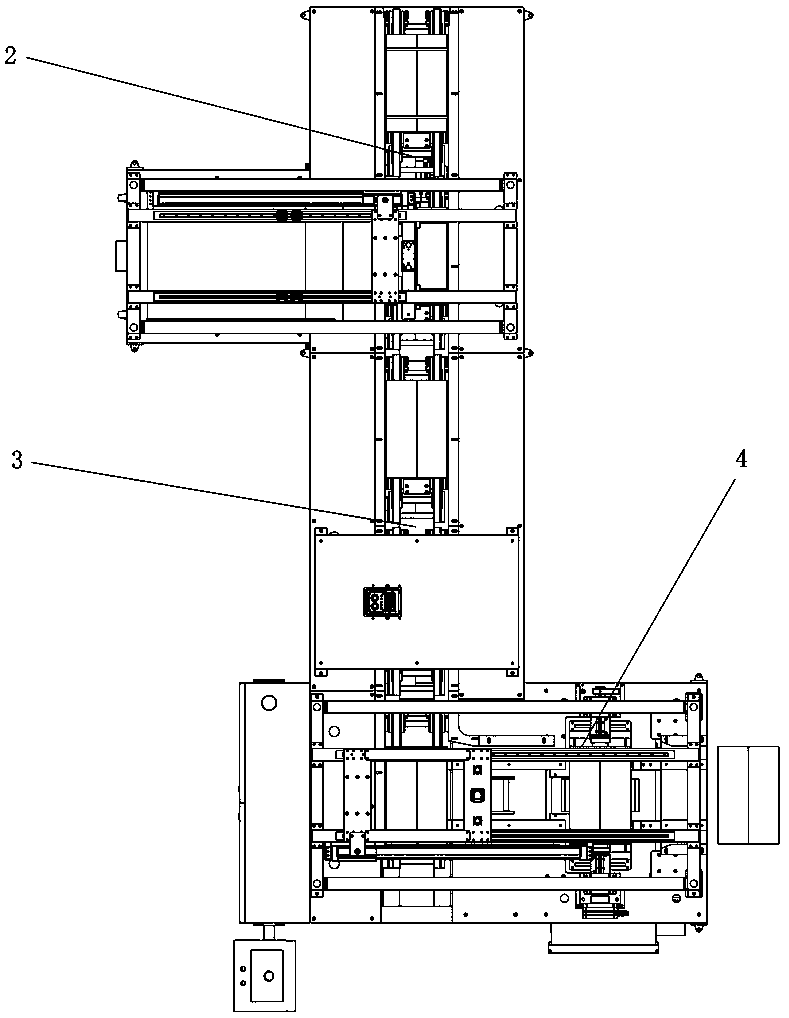

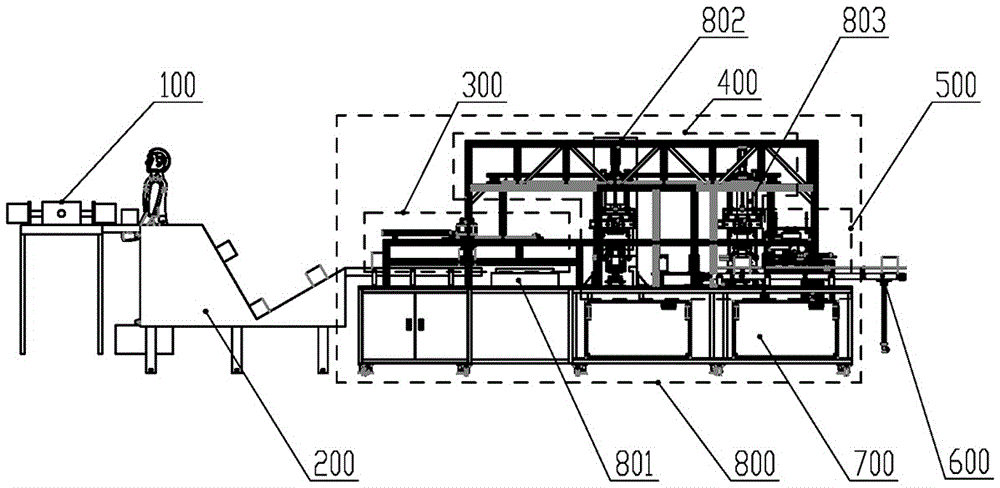

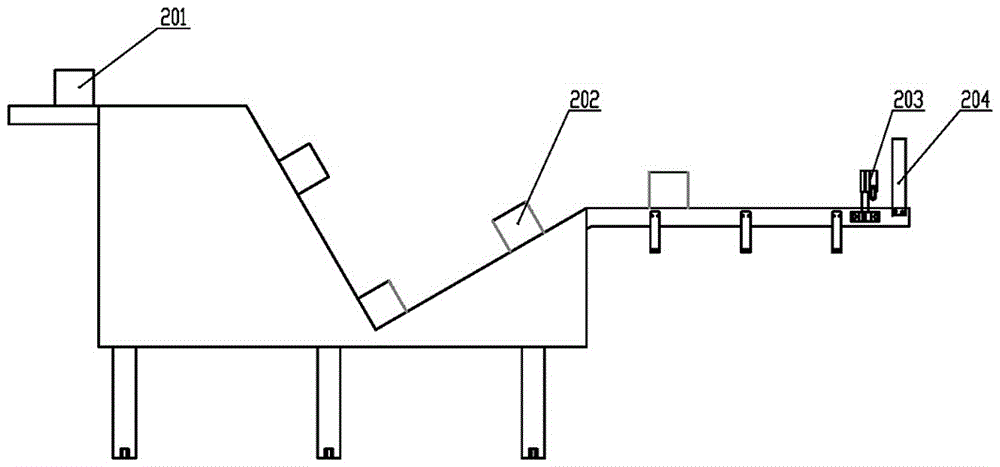

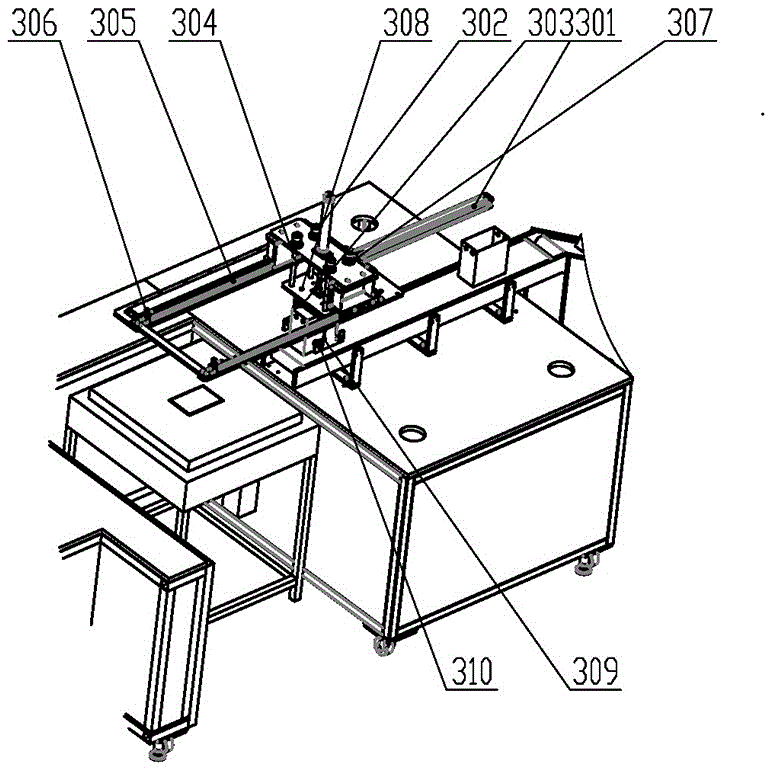

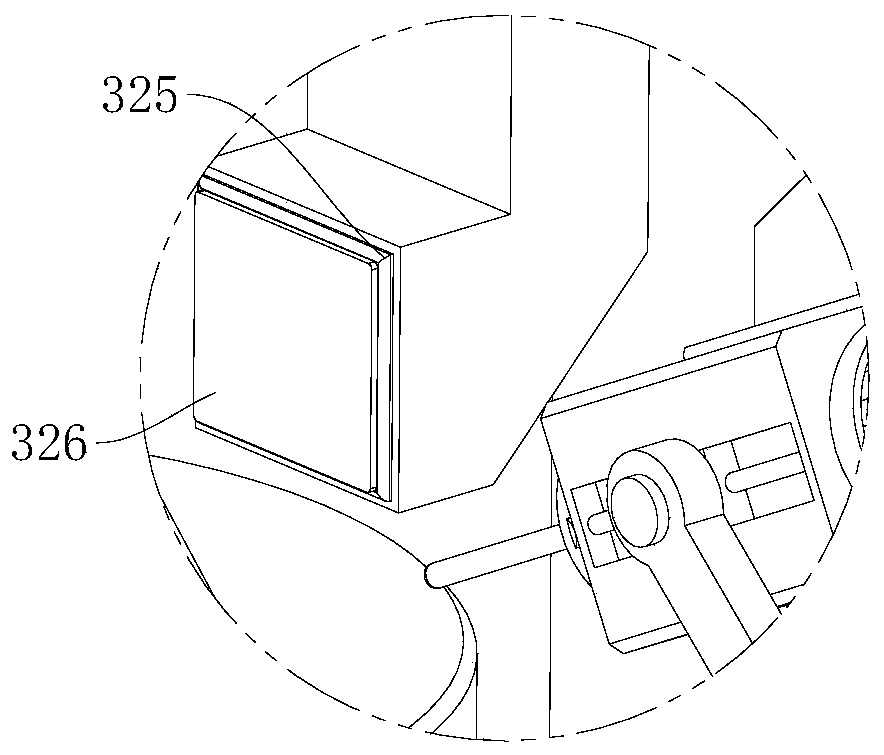

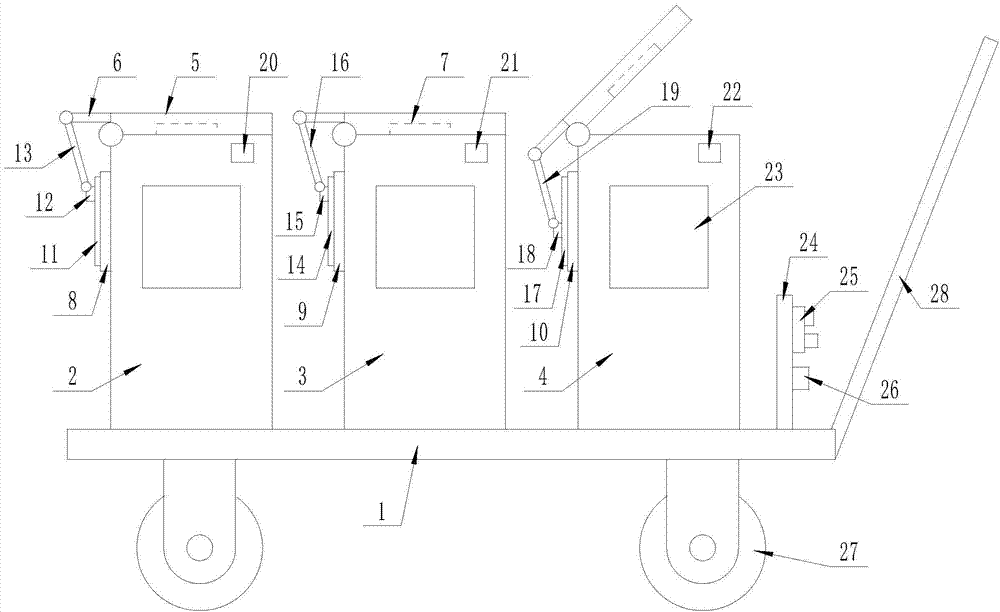

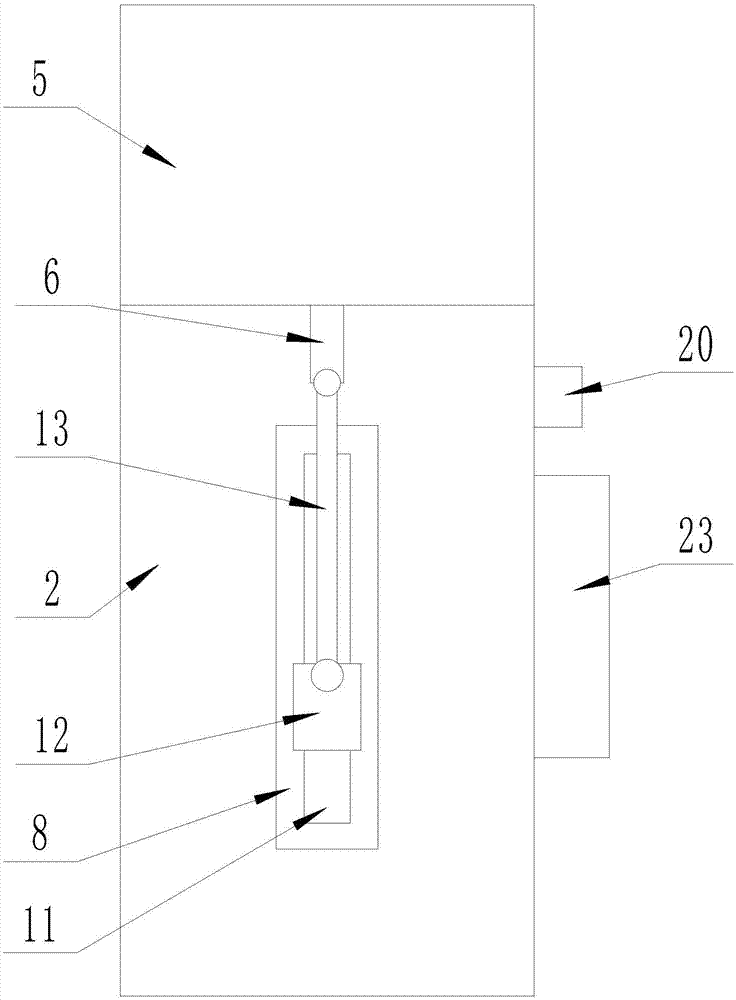

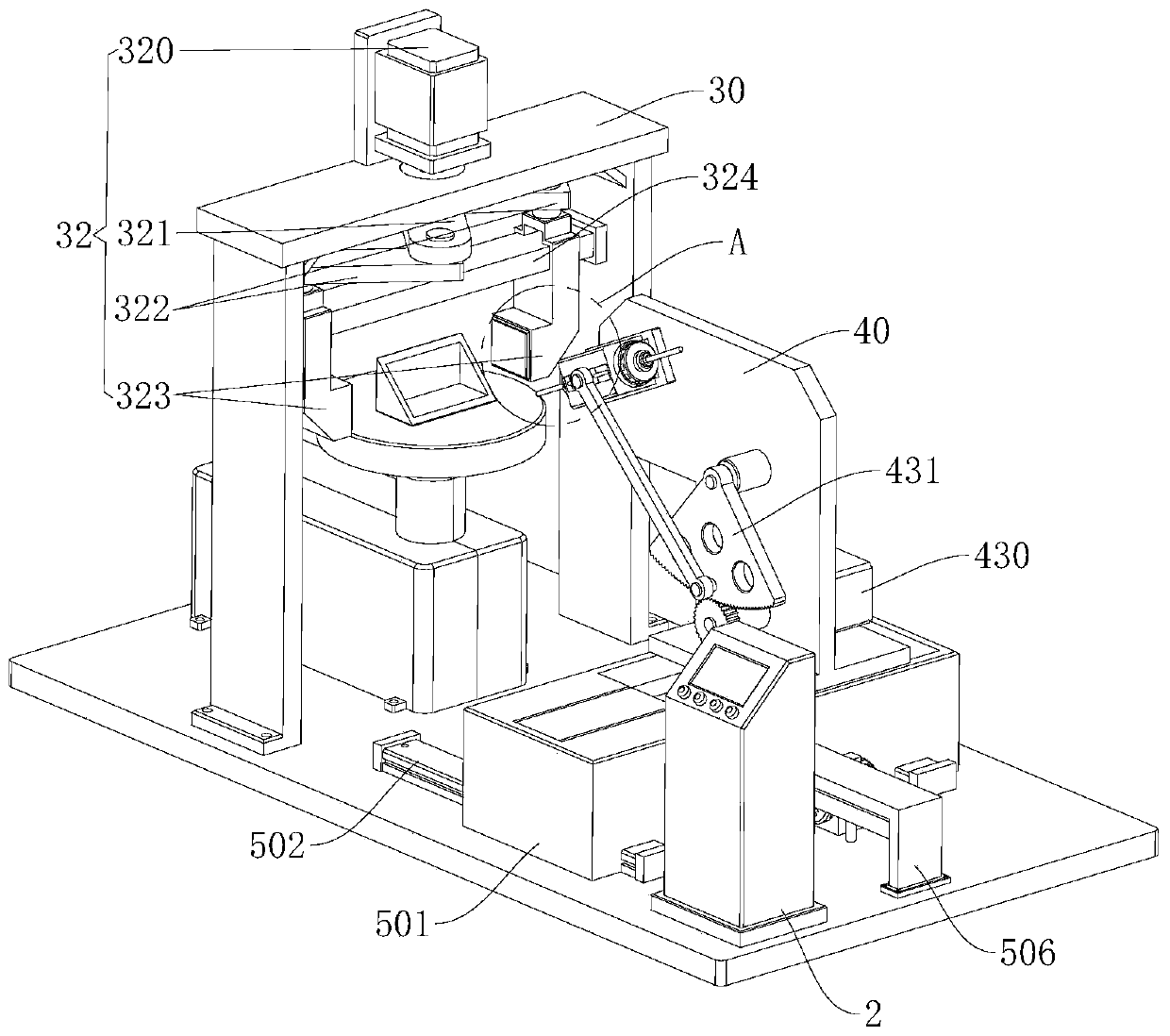

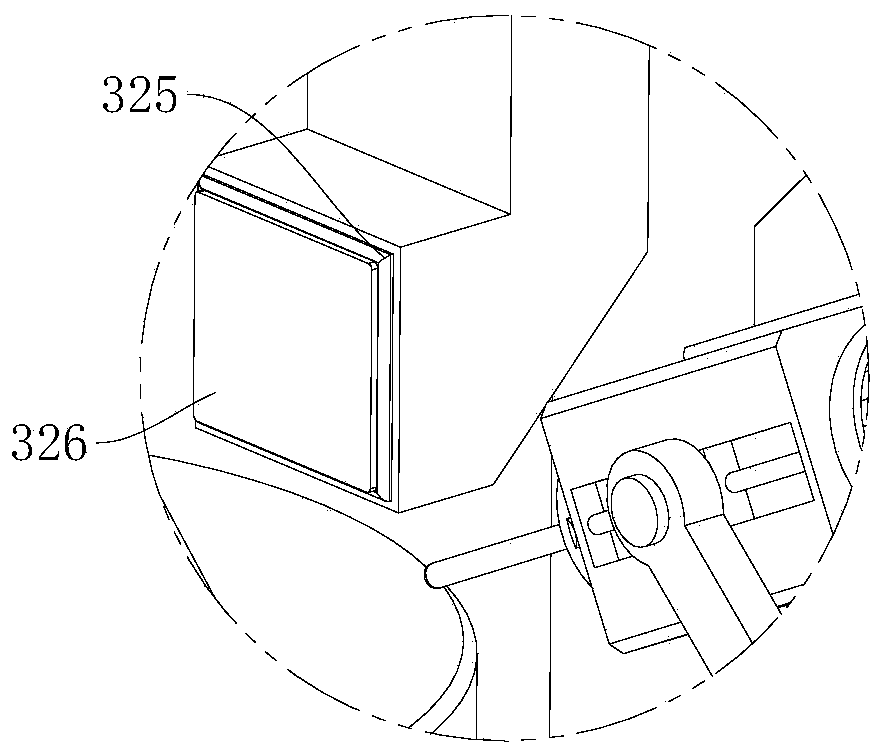

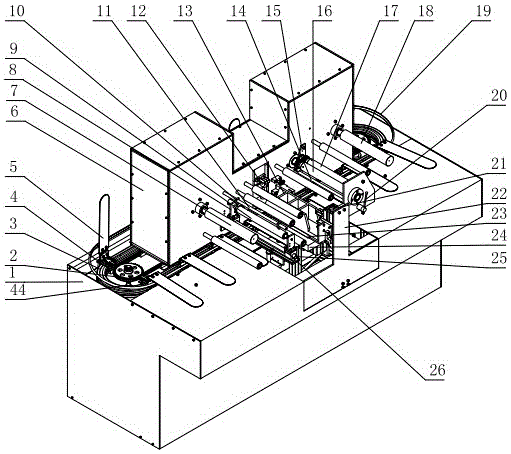

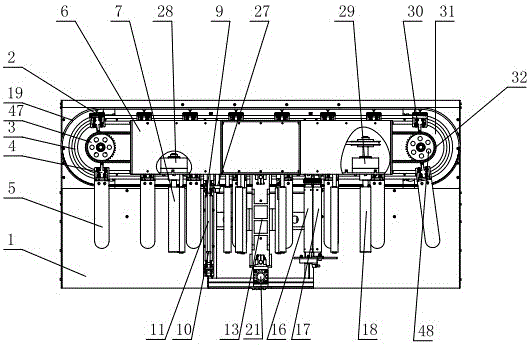

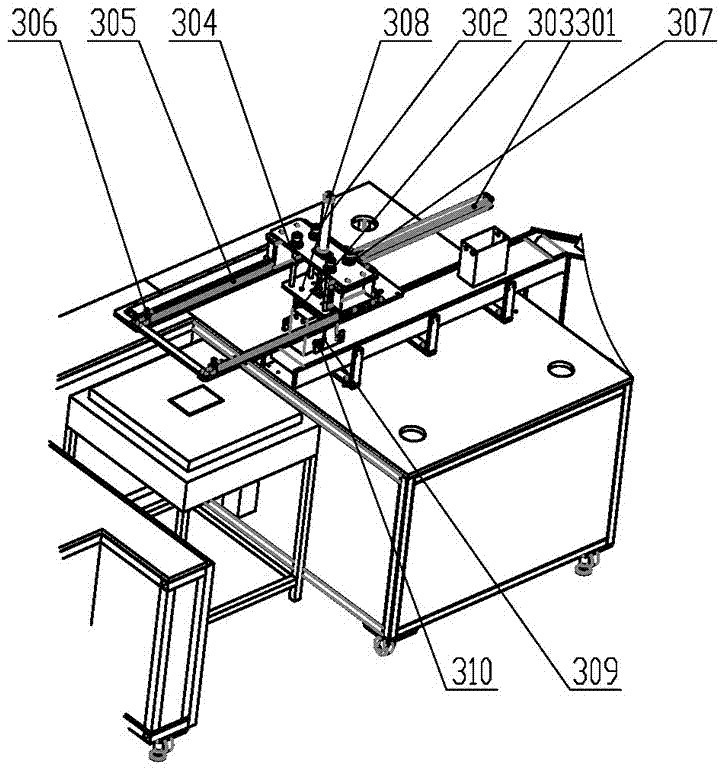

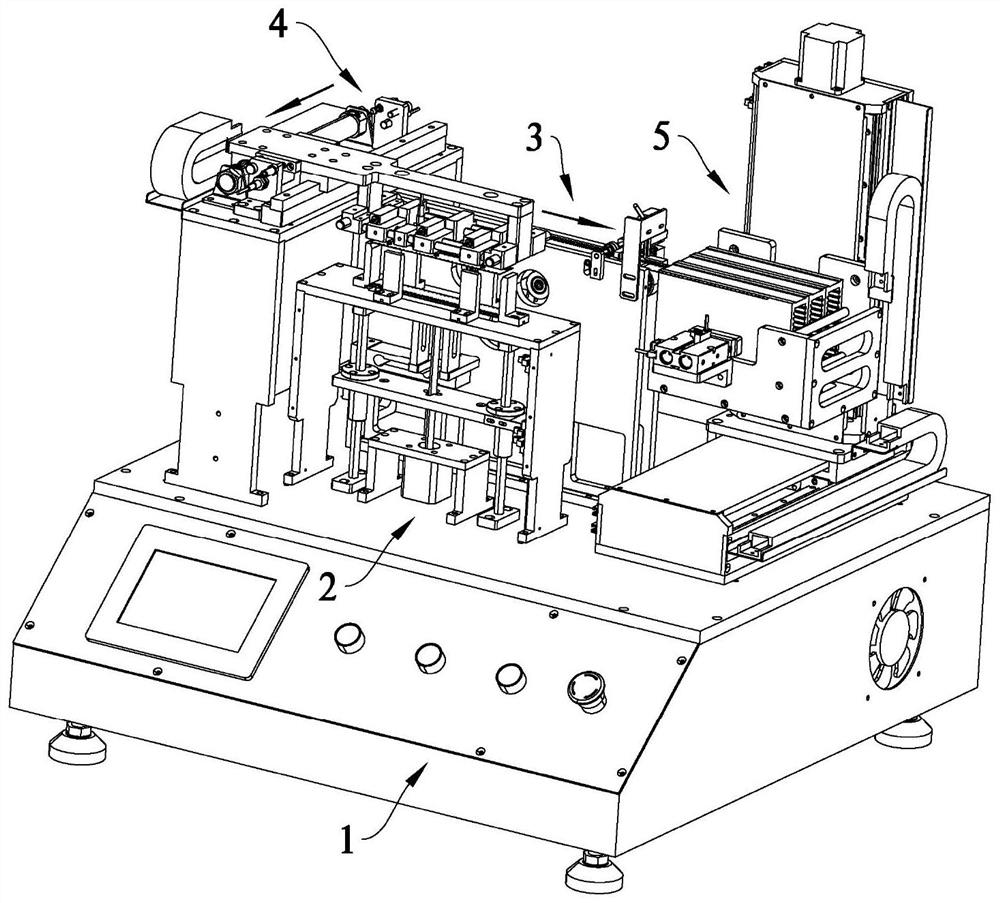

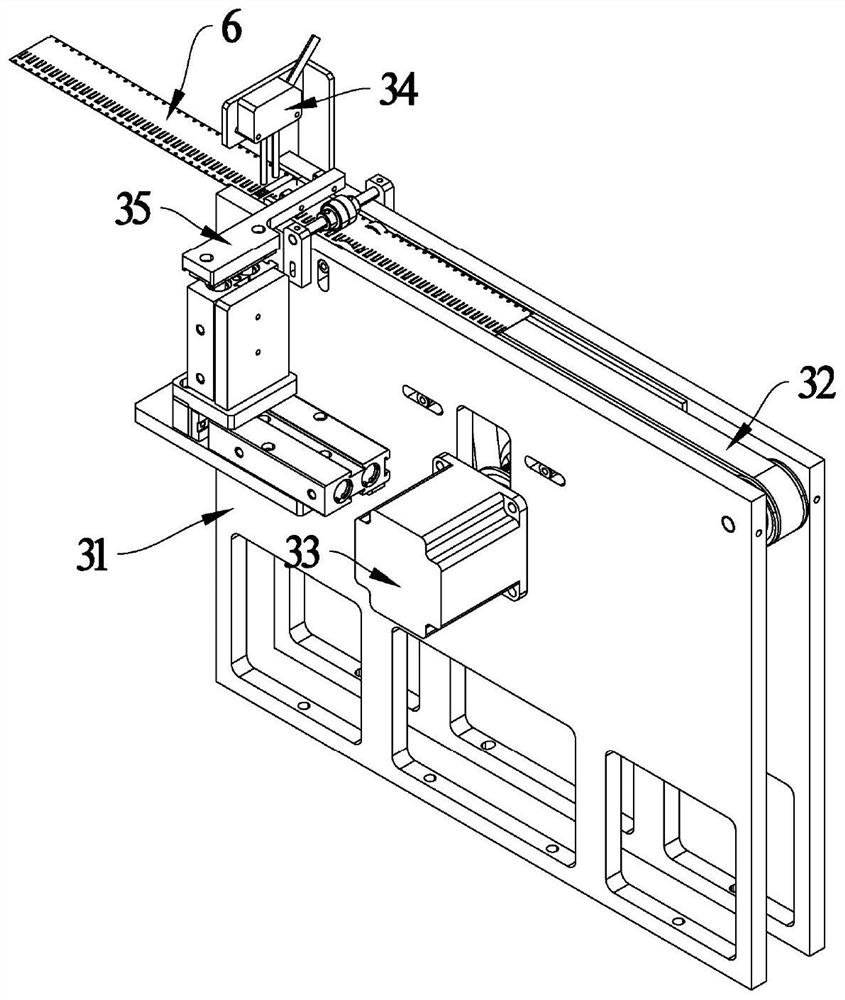

Intelligent box opening machine

PendingCN109677720AAvoid frequent contactReduce manual labor intensityBinding material removalUnpacking by cuttingAluminiumEngineering

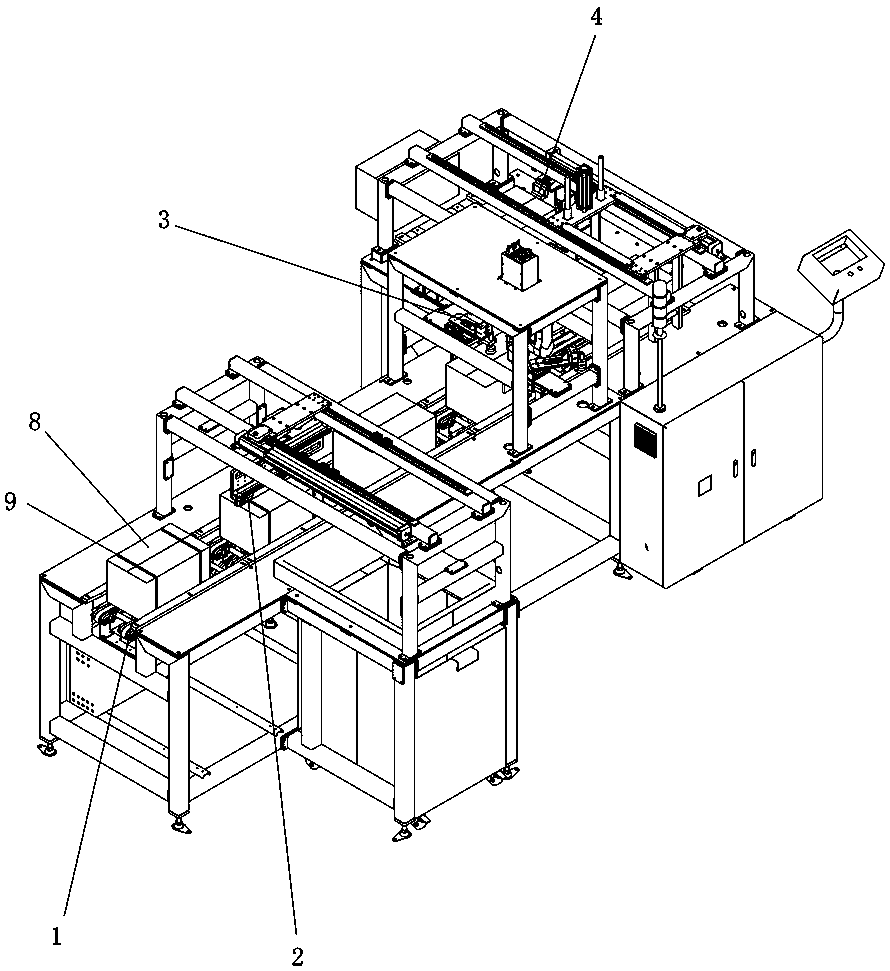

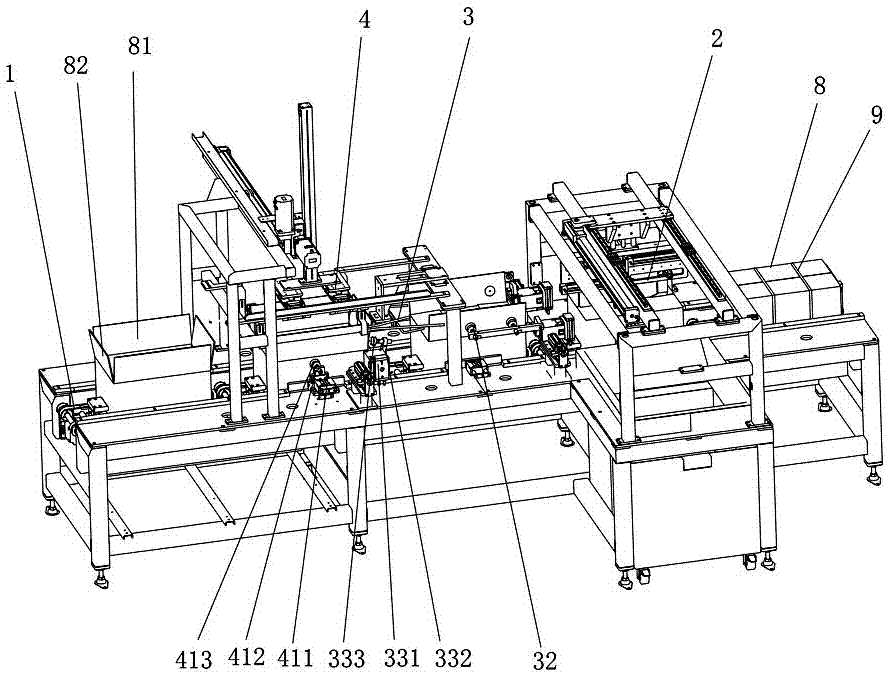

The invention discloses an intelligent box opening machine. The intelligent box opening machine comprises a box body conveying part, an automatic bundling tape removing device, an automatic adhesive tape cutting device and an automatic blanking device, wherein a cutting station, a removing station and an adhesive tape cutting station are successively arranged along a conveying direction of the boxbody conveying part; the automatic bundling tape removing device comprises a cutter component and a bundling tape removing component; the cutter component is arranged in the cutting station and is capable of cutting bundling tapes at the bottoms of packaging boxes when the box body conveying part is used for conveying the packaging boxes to the removing station; the bundling tape removing component is arranged in the removing station and is capable of removing the cut bundling tapes; the automatic adhesive tape cutting device is arranged in the adhesive tape cutting station and is capable ofcutting adhesive tapes on the packaging boxes; the automatic blanking device is butted with the output end of the box body conveying part and is capable of clamping the packaging boxes, then overturning the packaging boxes and pouring aluminum cover packages out. The intelligent box opening machine has the advantages of high automation degree, high production efficiency and low pollution risk.

Owner:TRUKING TECH LTD

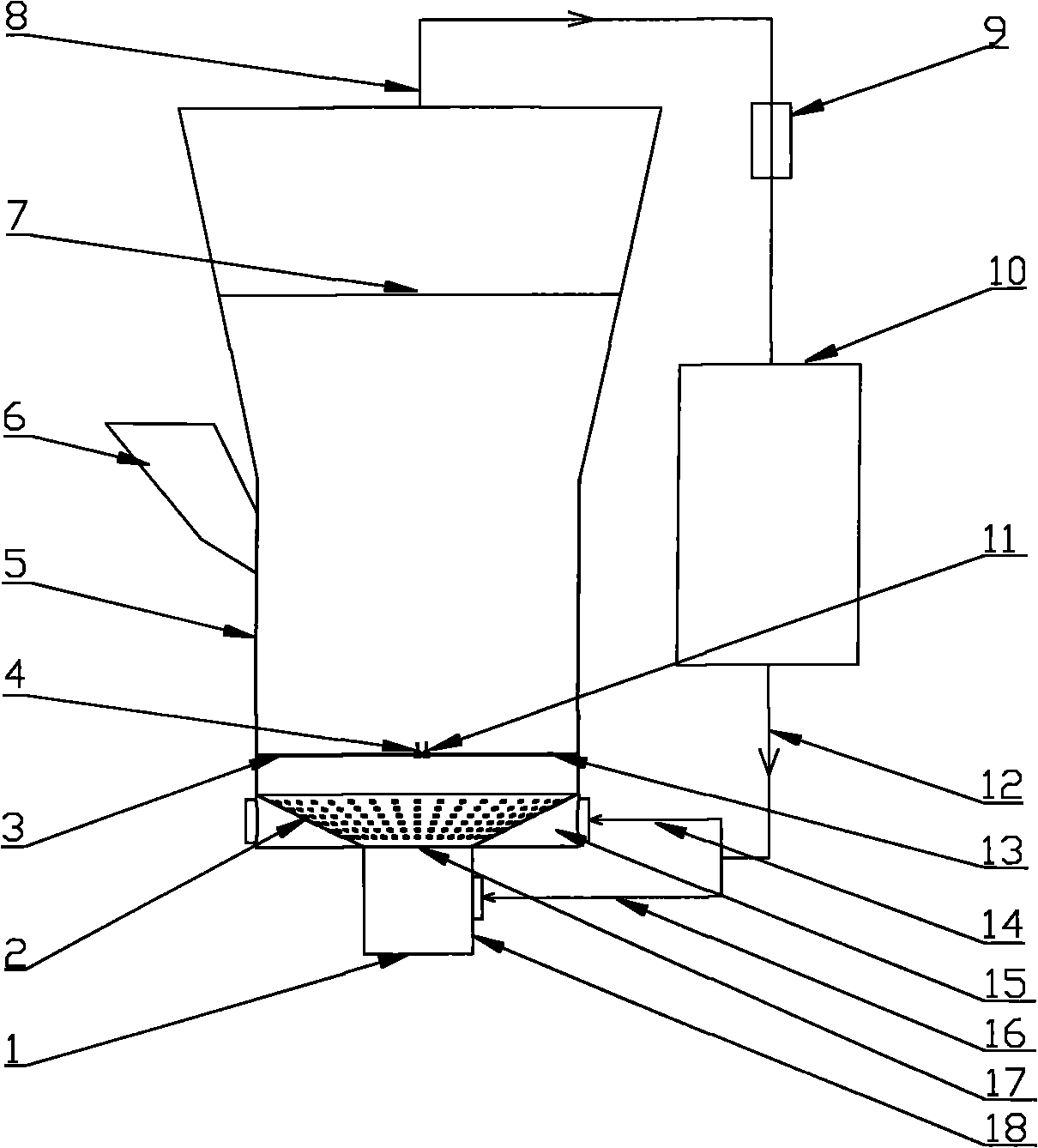

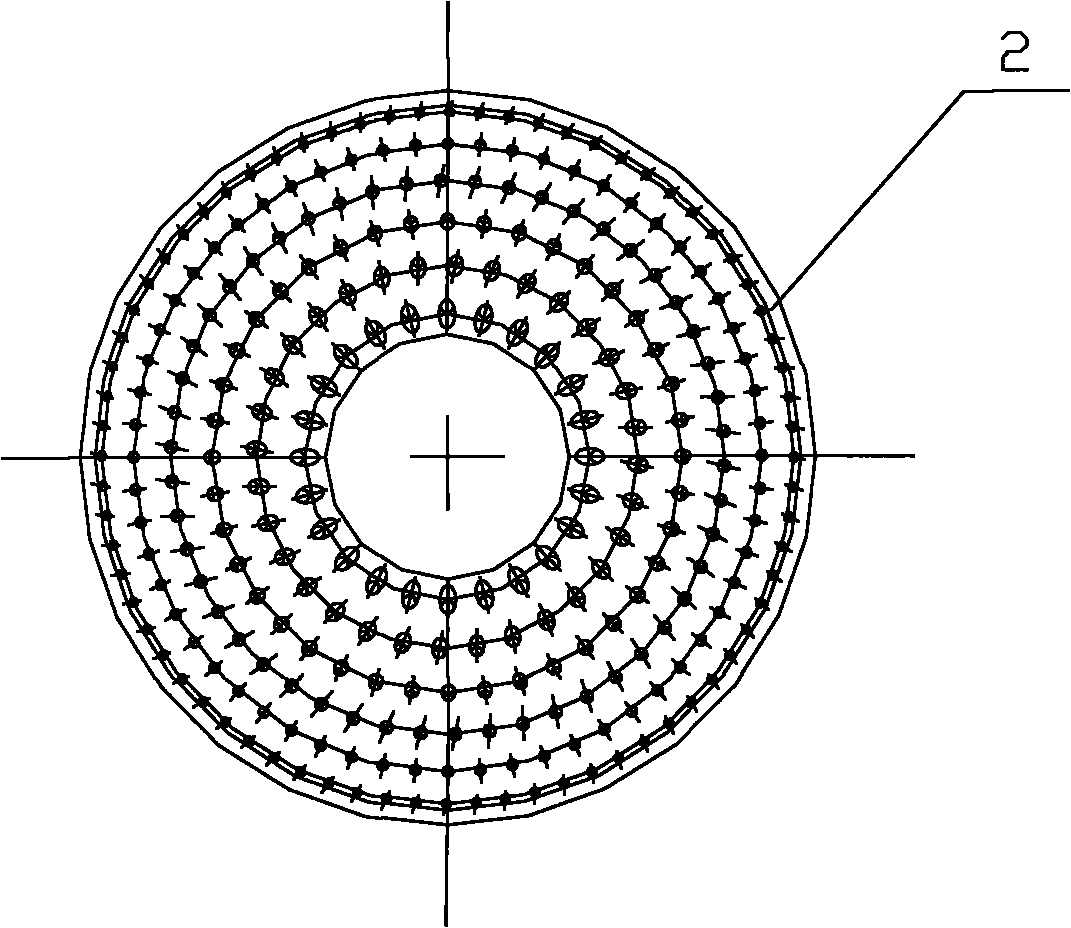

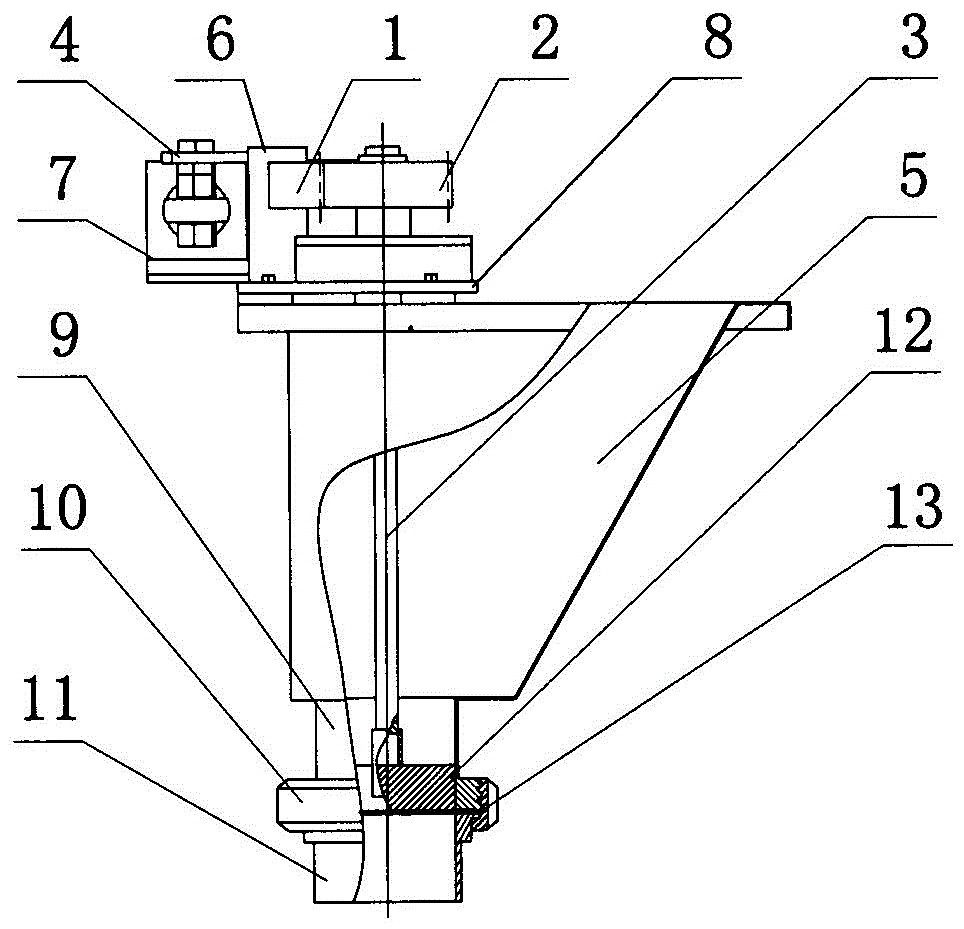

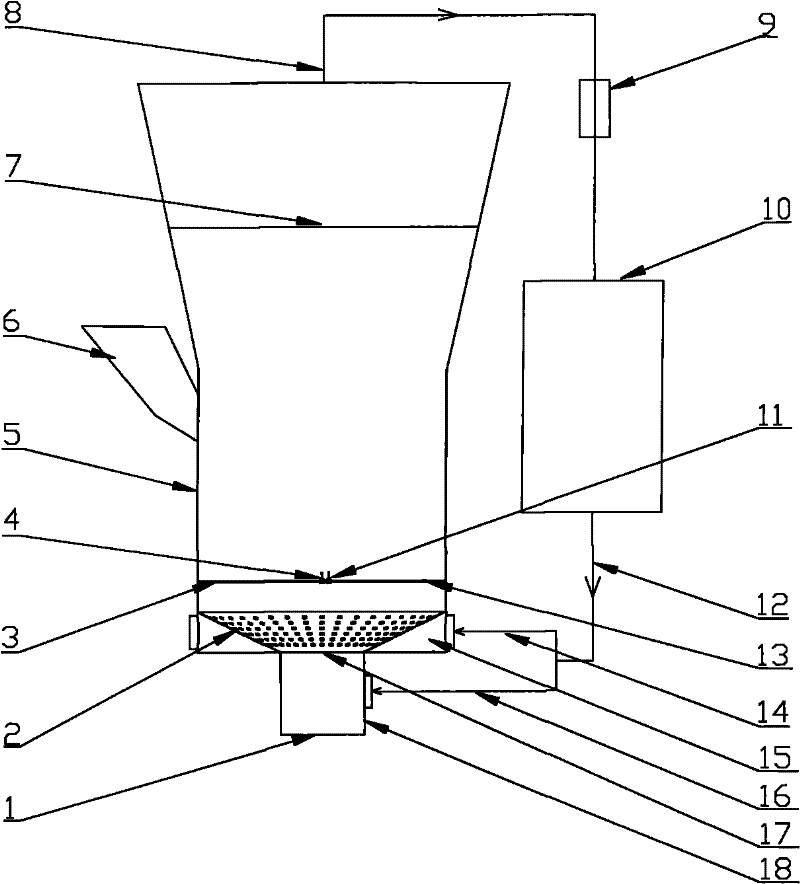

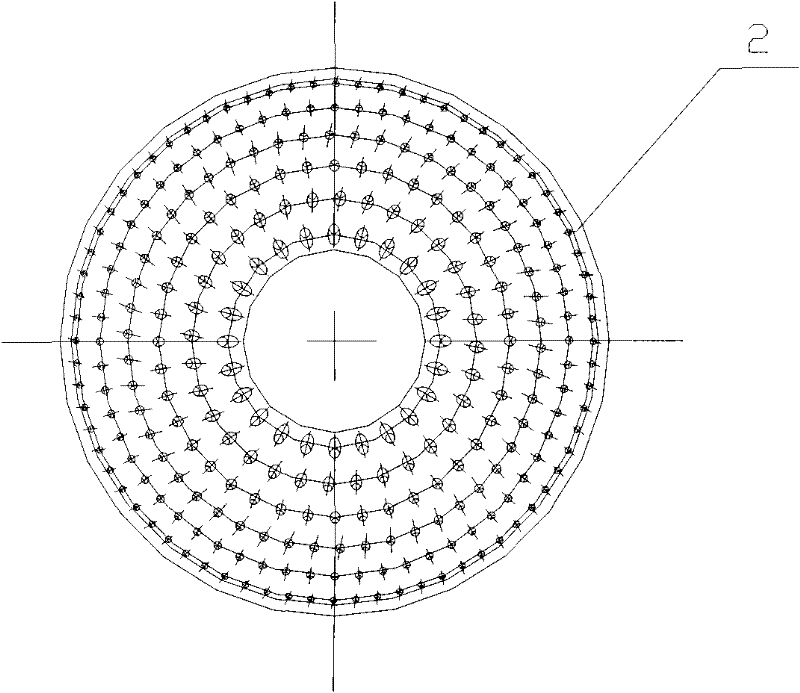

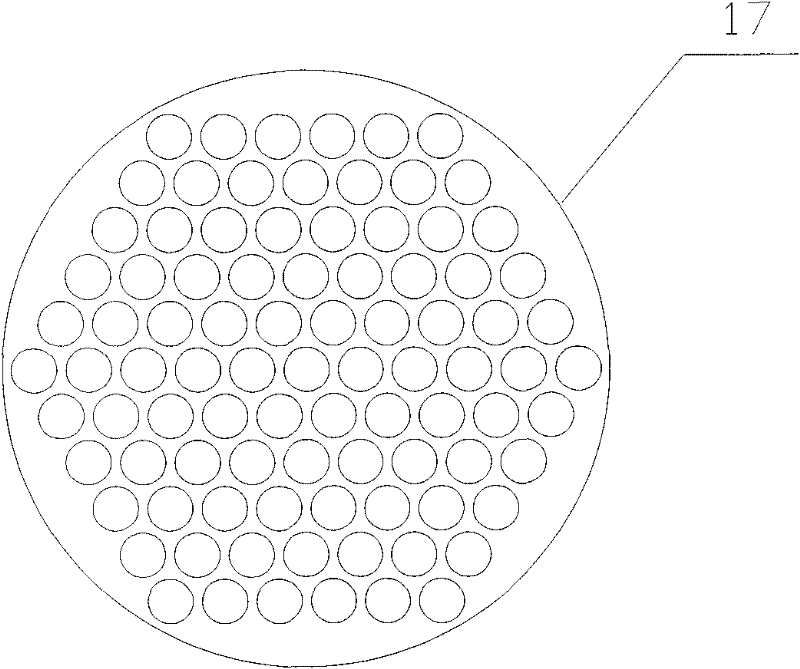

Vertical pneumatic bending, flavoring and feeding device

The invention discloses a vertical pneumatic bending, flavoring and feeding device. The device comprises a tobacco feed hopper, a main working cylinder, a flavoring and feeding nozzle, a bracket and a pipeline of the flavoring and feeding nozzle, a warming and humidifying nozzle, a bracket and a pipeline of the warming and humidifying nozzle, a tobacco filter screen, a feed liquid filter core, a hot air circulating system, a hot air pipeline of the hot air circulating system, an air-distributing system and a discharge gate, wherein the air-distributing system consists of a conical air-distributing plate, a periphery airflow air supply pipeline, a periphery airflow chamber, a central airflow air supply pipeline, a central airflow pipeline and a center hole plate; the feed hopper is positioned on a side wall of the main working cylinder; and the tobacco filter screen, the flavoring and feeding nozzle, the bracket and the pipeline of the flavoring and feeding nozzle, the warming and humidifying nozzle and the bracket and the pipeline of the warming and humidifying nozzle are sequentially arranged from top to bottom in the main working cylinder. In the device, tobaccos violently rotate and tumble in the cylinder under the action of two airflows of a bottom center hole plate and a conical hole plate having spiral holes; the flavoring and feeding nozzle performs flavoring and feeding on the tobaccos in violent motion; and the applied feed liquid is more uniform.

Owner:NANJING UNIV OF SCI & TECH +1

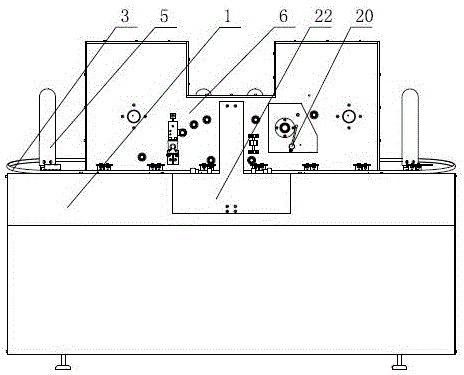

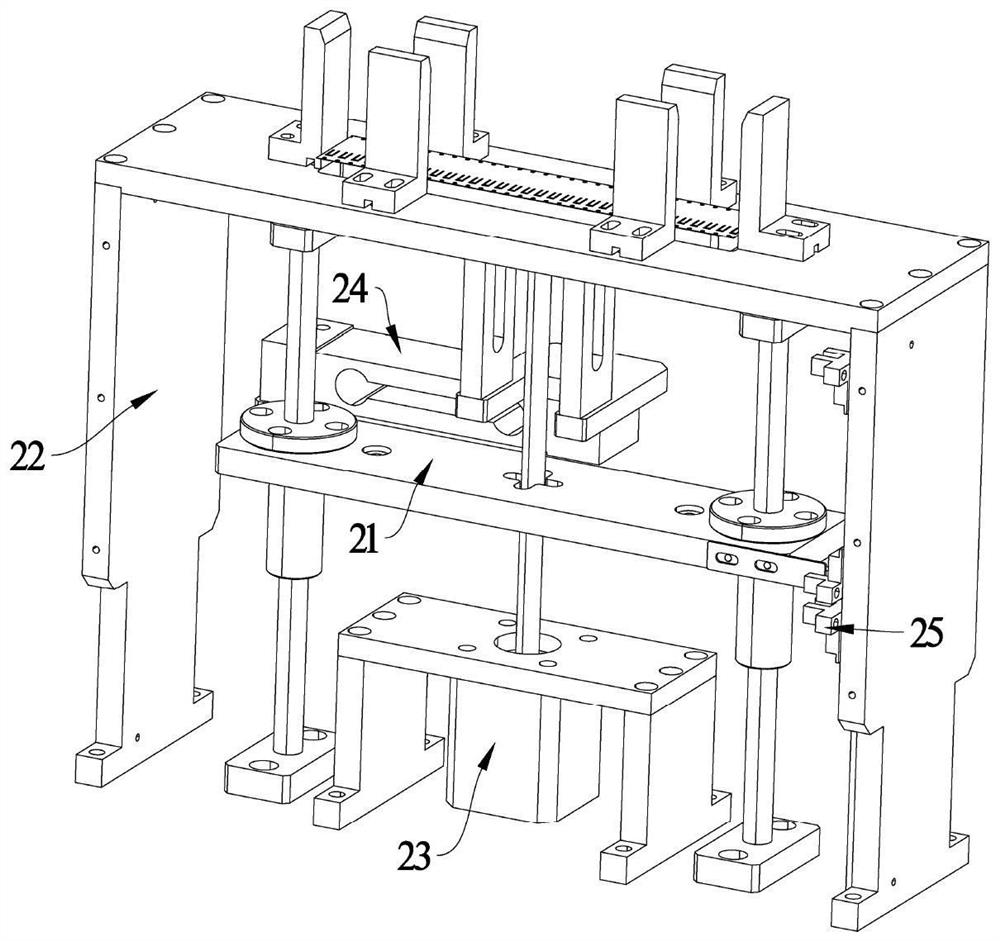

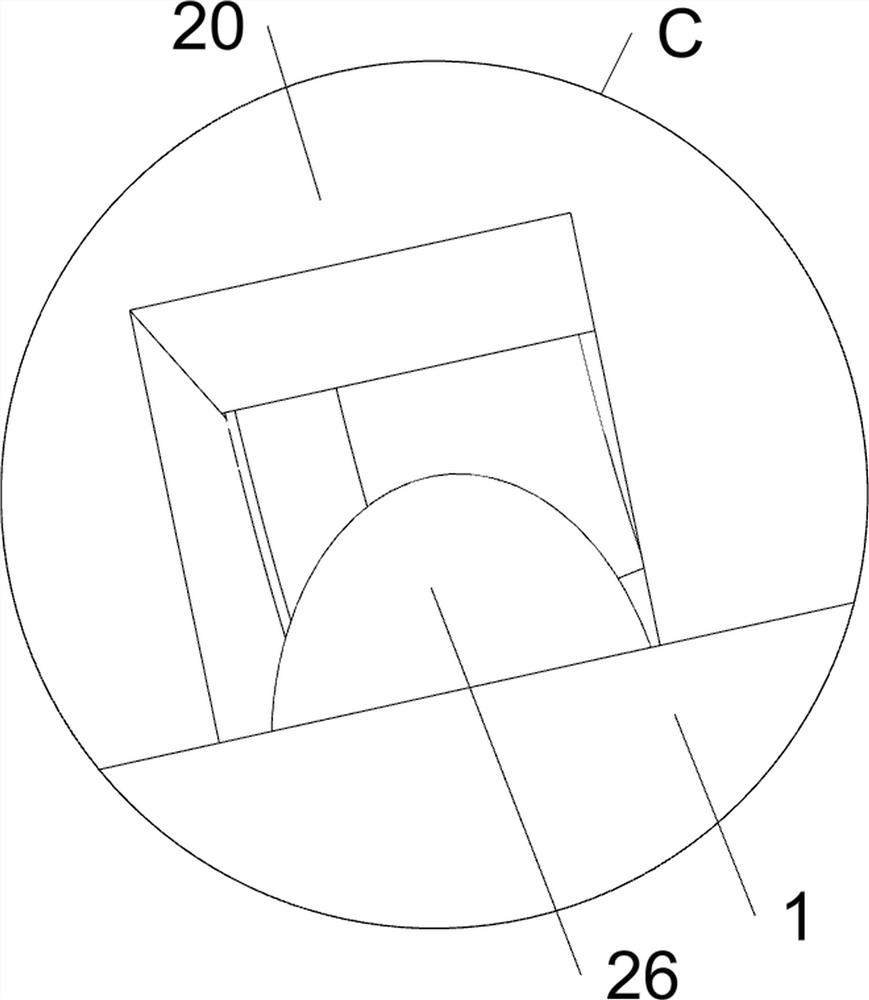

Intelligent box detaching machine

PendingCN107572078AAvoid frequent contactReduce manual labor intensityArticle unpackingEngineeringBottle

The invention discloses an intelligent box detaching machine. The intelligent box detaching machine comprises a box body conveying piece, an automatic bundling strip removing device, a hinge opening device and a bottle package taking-out device; a cutting station, a removing station and a box opening station are arranged in the conveying direction of the box body conveying piece in sequence; the automatic bundling strip removing device comprises a cutter assembly and a bundling strip removing assembly; the cutter assembly is arranged at the cutting station and can cut a bundling strip at the bottom of a package box when the package box is conveyed to the removing station by the box body conveying piece; the bundling strip removing assembly is arranged at the removing station and can removethe cut bundling strip after an outer hinge of the package box is lifted; the hinge opening device is arranged at the box opening station and can open the outer hinge and an inner hinge of the package box; and the bottle package taking-out device is arranged at the box opening station and can take the bottle package out from the package box after the outer hinge and the inner hinge are opened. The intelligent box detaching machine disclosed by the invention has the advantages of high automation degree, high production efficiency, low pollution risk and the like.

Owner:TRUKING TECH LTD

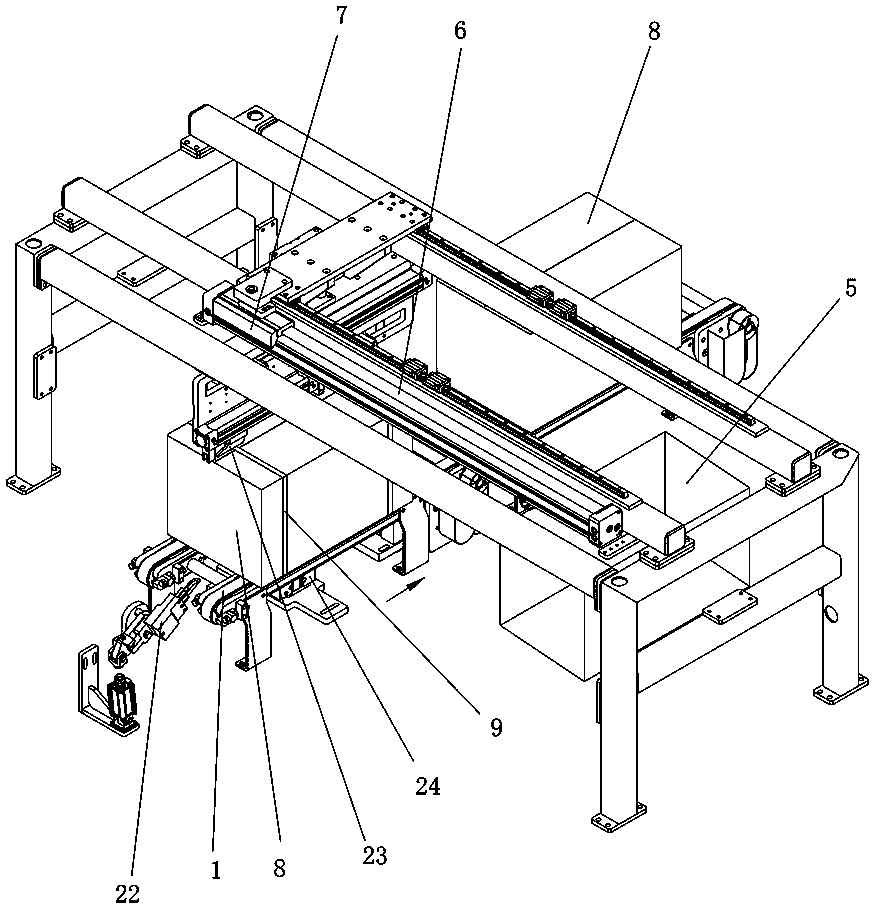

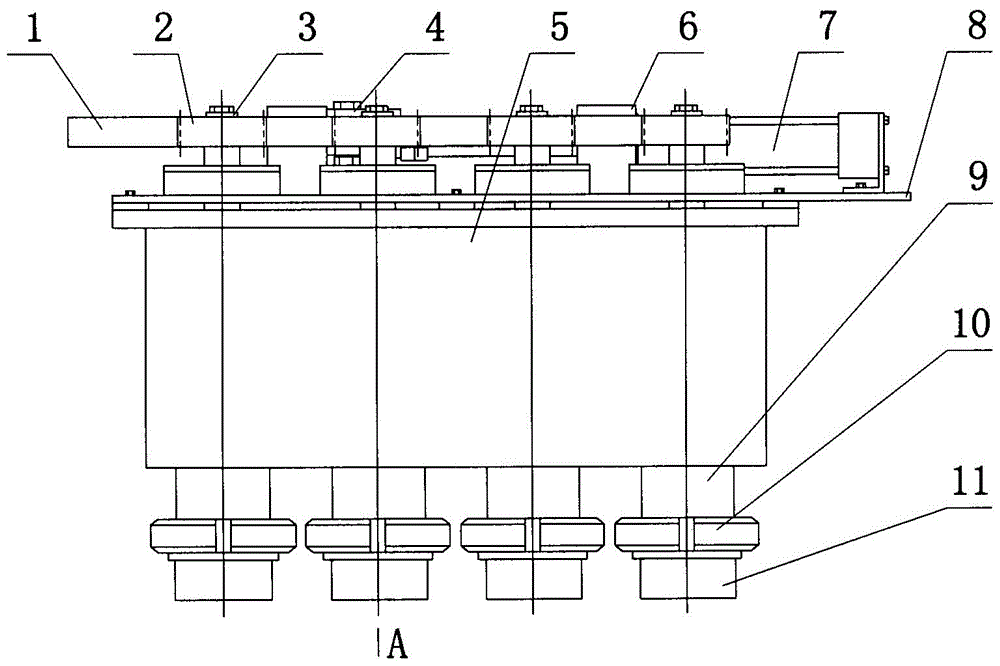

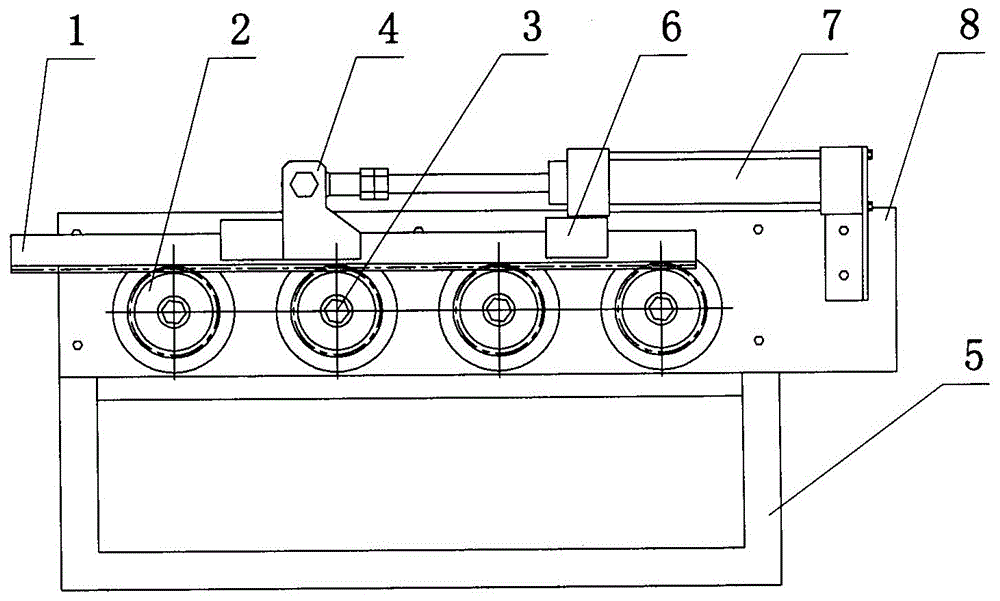

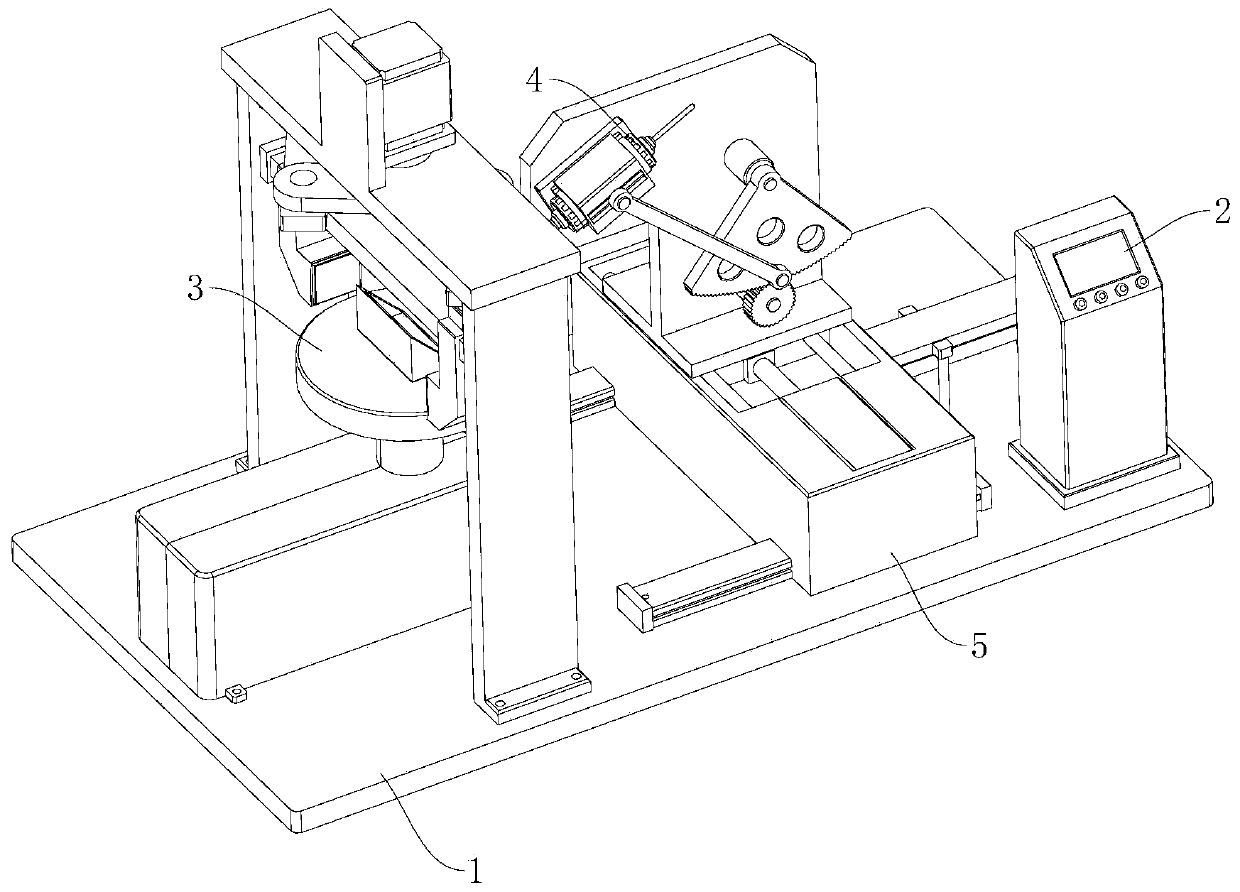

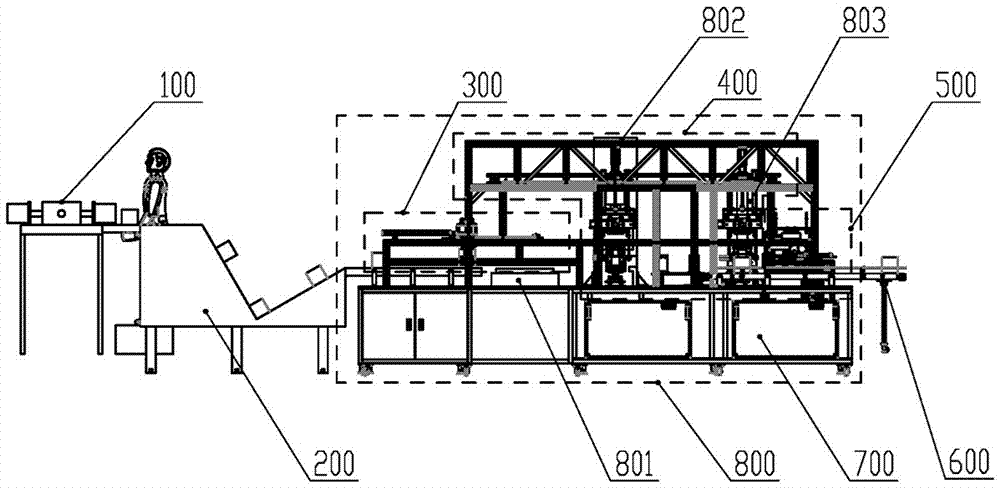

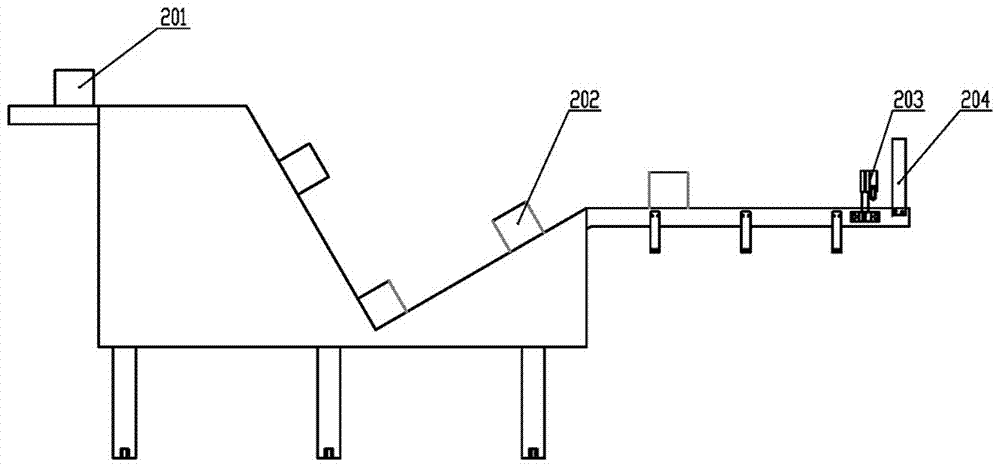

High-efficiency automatic square tank production line

ActiveCN105562546AAutomate operationSolve the clamping problemMetal-working feeding devicesStripping-off devicesProduction lineEngineering

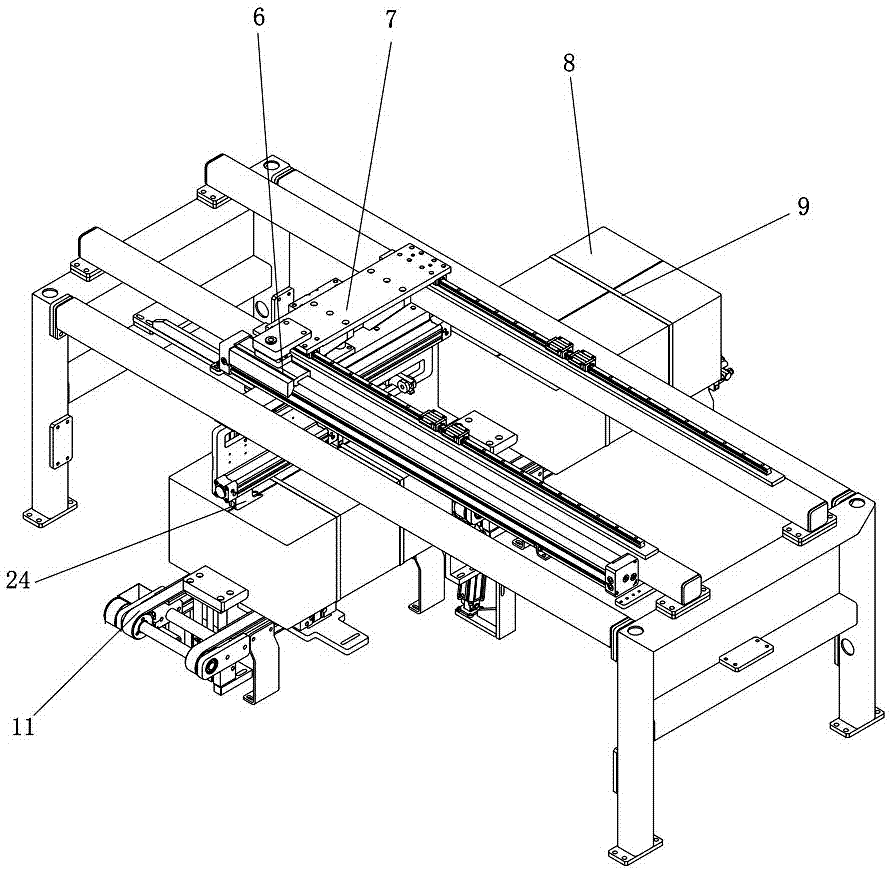

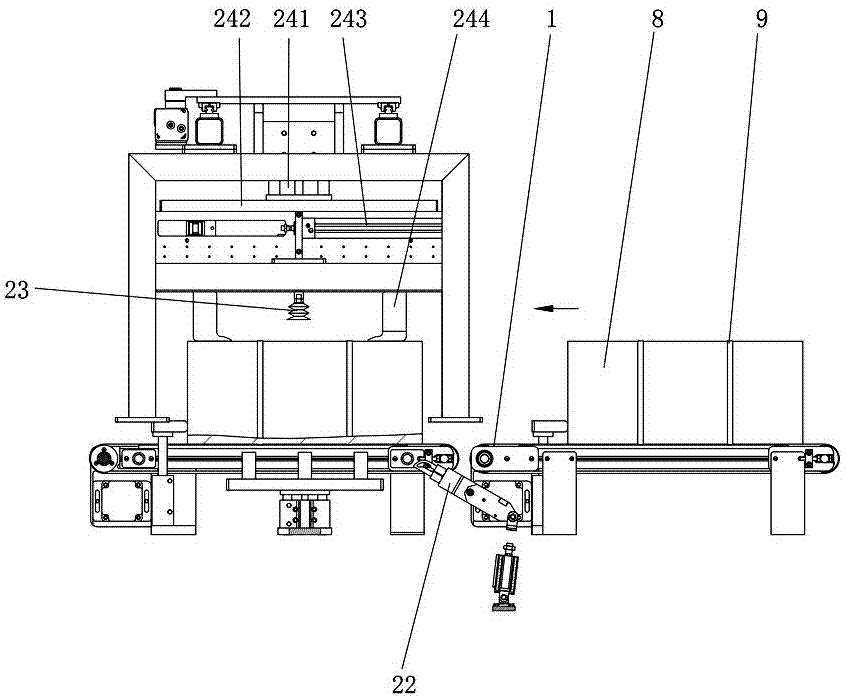

The invention discloses a high-efficiency automatic square tank production line. The high-efficiency automatic square tank production line comprises a forming device, a loading device, a conveying device module I, a conveying device module II, a conveying device module III, a machining device, an unloading device and a control box. The loading device and the unloading device are arranged on the front and back sides of a conveying device in parallel to realize automatic loading and unloading of square tanks. The conveying device module I, the conveying device module II and the conveying device module III are positioned between left and right stand columns of the machining device to realize conveying of the square tanks; and the machining device clamps the square tanks. The machining device is positioned in the middle of the production line; a main shaft part of the machining device can realize high-efficiency machining of the tanks; and the control box is positioned in a production line welding box to control operation of the production line. The high-efficiency automatic square tank production line realizes forming, loading / unloading, conveying, clamping and machining automation of the square tanks based on a mechanical-electrical integration principle, simplifies the machining process, improves the production efficiency, can reduce the worker number, and reduces the potential safety hazard in the production process.

Owner:TAIZHOU LANYI INTELLIGENT EQUIP TECH CO LTD

Mechanical powder scattering machine for frozen drink surface

InactiveCN106135624AQuality improvementImprove aestheticsFrozen sweetsReciprocating motionStorage tank

The invention relates to a mechanical powder scattering machine for a frozen drink surface. The mechanical powder scattering machine is used for solving the problems of uneven scattered powder on the frozen drink surface and difficulty in quantitative control on thickness. The mechanical powder scattering machine comprises a storage tank, a fixing plate, a powder supply pipe, a powder scattering pipe, a power source and a reciprocating type transmission mechanism which are connected together. The technical essential is as follows: the reciprocating type transmission mechanism driven by the power source is driven to have a reciprocating motion by a linking base, and meanwhile, a rack is driven to move along a guiding slide block, a gear meshed with the rack is driven to rotate back and forth, a shifting sheet shaft with the top fixed with the gear is driven to synchronously rotate, the shifting sheet and the surface of a stainless steel screen have rotating friction and micro-vibration, the powder in the powder supply pipe enters into the powder scattering pipe through the stainless steel screen, and then the powder scattering action is finished. The structure design is reasonable, the surface powder scattering is uniform, the quantitative control on thickness of scattered powder is accurate, the powder scattered defective product is effectively prevented, the efficiency of labor and the quality of frozen drink are obviously increased, the loss and waste of raw materials are reduced, the production cost is lowered, the environment is not polluted and the health of human body is benefited.

Owner:SHENYANG DESHI COLD DRINKS & FOODSTUFF CO LTD

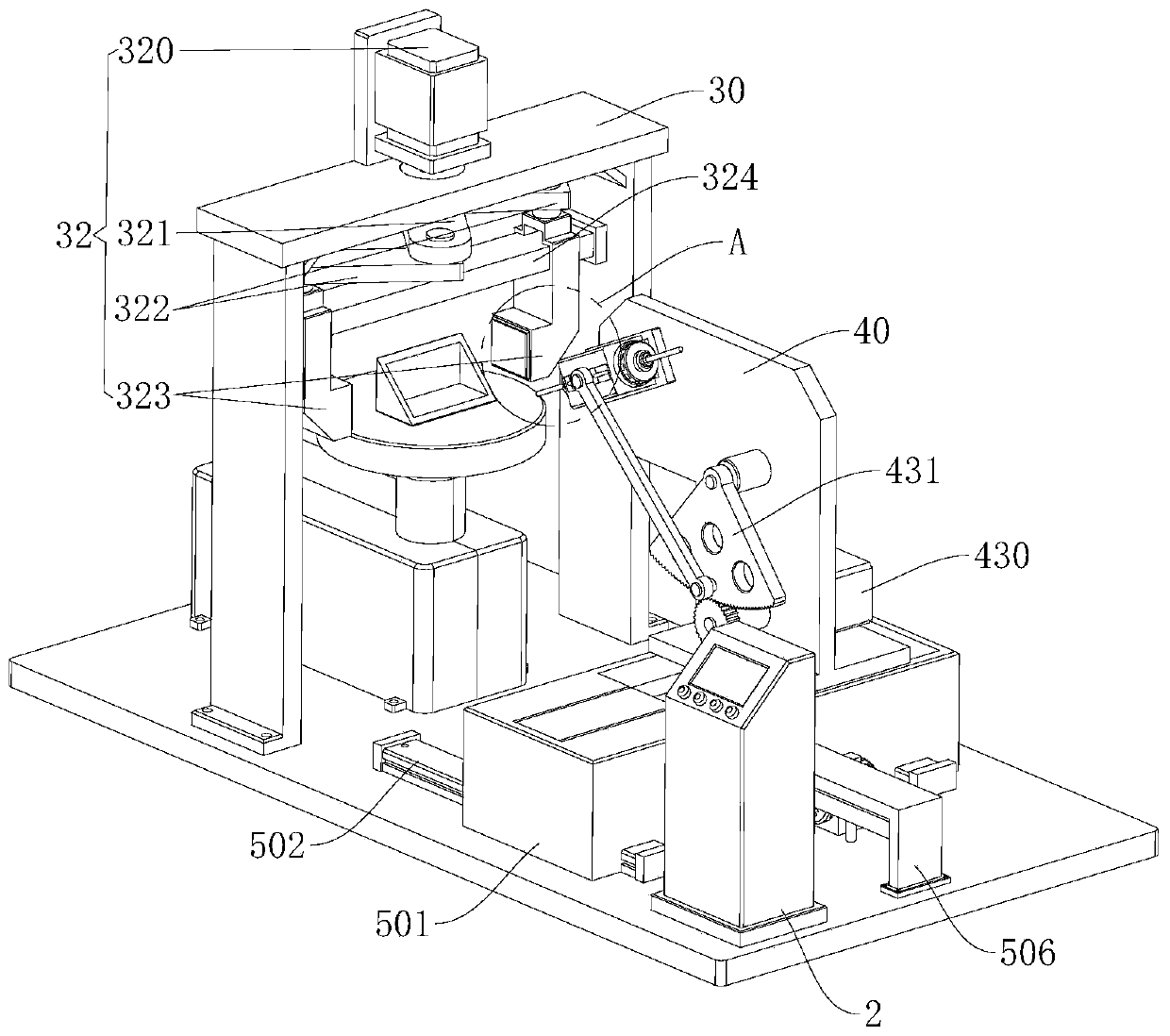

Component of machining equipment for aluminum alloy corner wrapping block

InactiveCN111300049AReduce processing timeReduce manufacturing costOther manufacturing equipments/toolsMetal machiningMaterials science

The invention relates to the technical field of metal machining, in particular to a component of machining equipment for an aluminum alloy corner wrapping block. The component comprises a base, and further comprises a controller, a fixing mechanism, a machining mechanism and a sliding mechanism, wherein the fixing mechanism comprises a supporting frame, a machining table, a clamping component anda first corner adjusting component; the sliding mechanism comprises a pushing component and a sliding component; the machining mechanism comprises a supporting plate, a grinding component, a drillingcomponent and a second corner adjusting component; the clamping component, the first corner adjusting component, the pushing component, the sliding component, the grinding component, the drilling component and the second corner adjusting component are all electrically connected with the controller. Through the component of the machining equipment for an aluminum alloy corner wrapping block and themachining method thereof, grinding and drilling procedures of aluminum alloy corner wrapping block can be alternately carried out without being sequentially carried out on duty, the working efficiency is improved, meanwhile, aluminum alloy corner wrapping blocks of different sizes can be machined, workers can be prevented from making contact with a machining table frequently, and potential safetyhazards are effectively reduced.

Owner:朱明德

Temporary storage device for medical waste products

InactiveCN107572165AAvoid virus growthAvoid frequent contactWaste collection and transferRefuse receptaclesMedical productHinge angle

The invention discloses a temporary storage device for medical waste products. The temporary storage device for the medical waste products comprises a rectangular base, a first storing barrel, a second storing barrel and a third storing barrel are arranged on the upper surface of the rectangular base, sealing buckle covers are connected to the upper surfaces of the first storing barrel, the secondstoring barrel and the third storing barrel through hinges, the side surface of each sealing buckle cover is provided with a horizontal pull rod, an ultraviolet sterilizing lamp is mounted on the upper surface of the interior of each sealing buckle cover in an inlaid mode, the side surfaces of the first storing barrel, the second storing barrel and the third storing barrel are respectively provided with a first strip-shaped mounting plate, a second strip-shaped mounting plate and a third strip-shaped mounting plate, and the side surface of the first strip-shaped mounting plate is provided with a first strip-shaped slide rail. The temporary storage device has the beneficial effects that the device can temporarily sort and store the medical waste products, and can conduct continuous ultraviolet disinfection in the storing process so as to avoid virus breeding. And the device has an induction cover opening function so as to avoid frequent contact between the staff and the device.

Owner:闫淑军

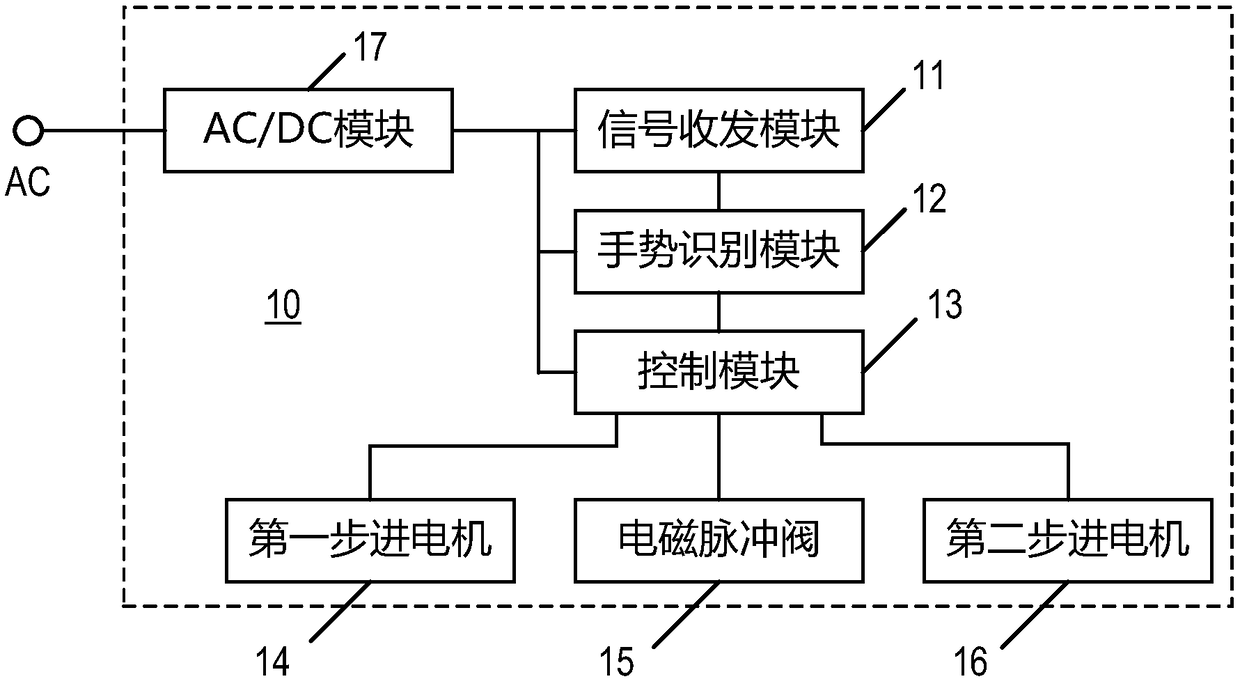

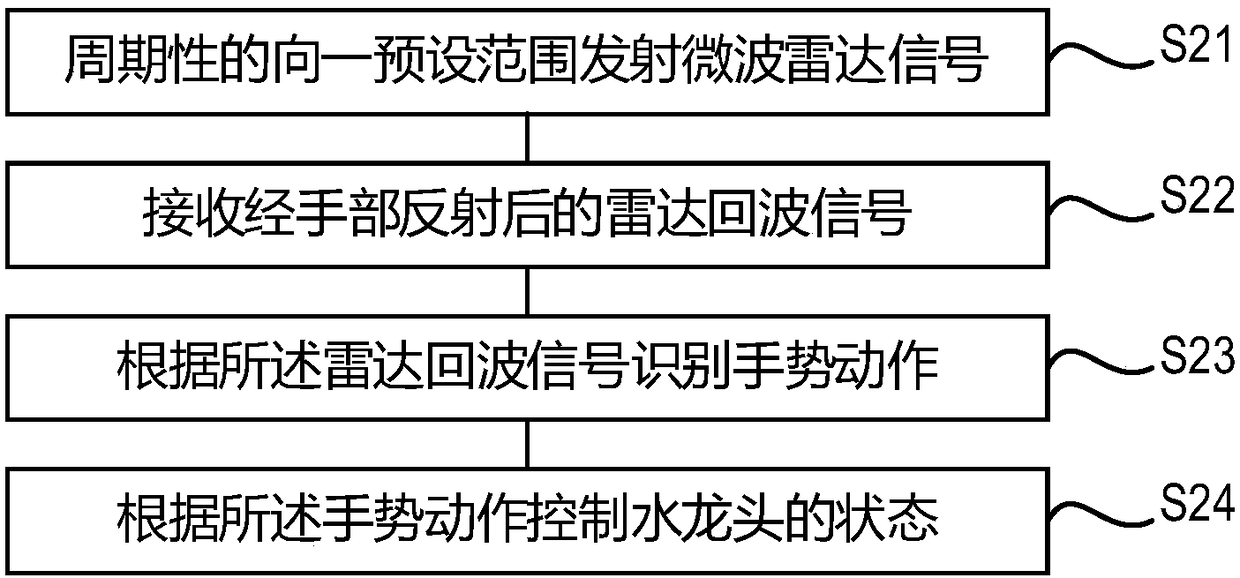

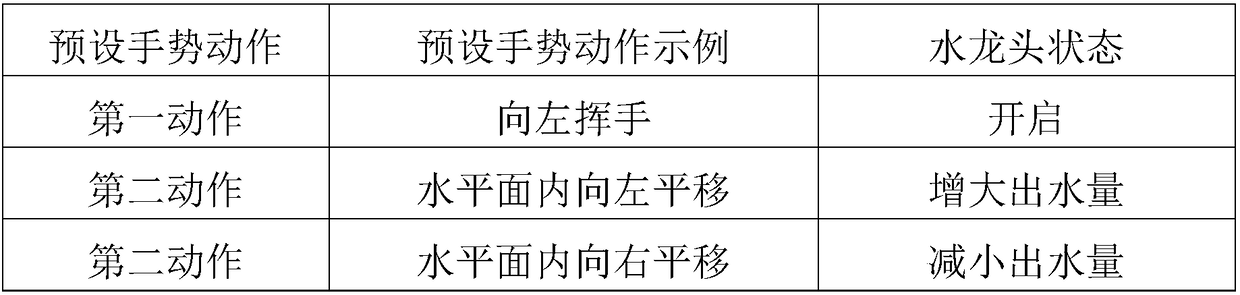

Water faucet based on microwave radar gesture recognition technology, and control method thereof

InactiveCN108343769AImprove intelligenceImprove ease of useOperating means/releasing devices for valvesCharacter and pattern recognitionMicrowave radarCross infections

The invention relates to the field of an information technology, in particular to a water faucet based on a microwave radar gesture recognition technology, and a control method thereof. The water faucet based on the microwave radar gesture recognition technology comprises a signal transmitting and receiving module, a gesture recognizing module and a control module, wherein the signal transmittingand receiving module is used for periodically transmitting a microwave radar signal to a preset range and receiving a radar echo signal reflected through a hand; the gesture recognizing module is connected with the signal transmitting and receiving module and is used for recognizing a gesture action according to the radar echo signal; and the control module is connected with the gesture recognizing module and is used for controlling a state of the water faucet according to the gesture action. According to the water faucet based on the microwave radar gesture recognition technology, and the control method thereof provided by the invention, a user is prevented from frequently touching the water faucet during a use process, so that the cross infection of bacteria and the spread of communicable diseases are completely eradicated, and the intelligence and the use convenience of the water faucet are improved.

Owner:AIRTOUCH SHANGHAI INTELLIGENT TECH CO LTD

Process for preparing musk pain-stopping spray

InactiveCN1729997APortableAvoid frequent contactAntipyreticAerosol deliveryHigh-density polyethyleneSpray bottle

Disclosed is a process for preparing musk pain-stopping spray, wherein the medicinal soup is loaded into purpose-made spraying bottles, the medicine spraying can be operated by hand-operated pressing, the spraying bottles are made of high-density polyethene or PET, the medicament in bottles is in normal pressure state all the time, it has the advantages of convenience in carrying, safety, quantitative spraying and easy control.

Owner:BAOTOU CHINESE TRADITIONAL MEDICINE

Wire arranging device

InactiveCN102765631AReduced chance of scratchesAvoid frequent contactFilament handlingEngineeringMechanical engineering

Owner:大连环新新材料科技有限公司

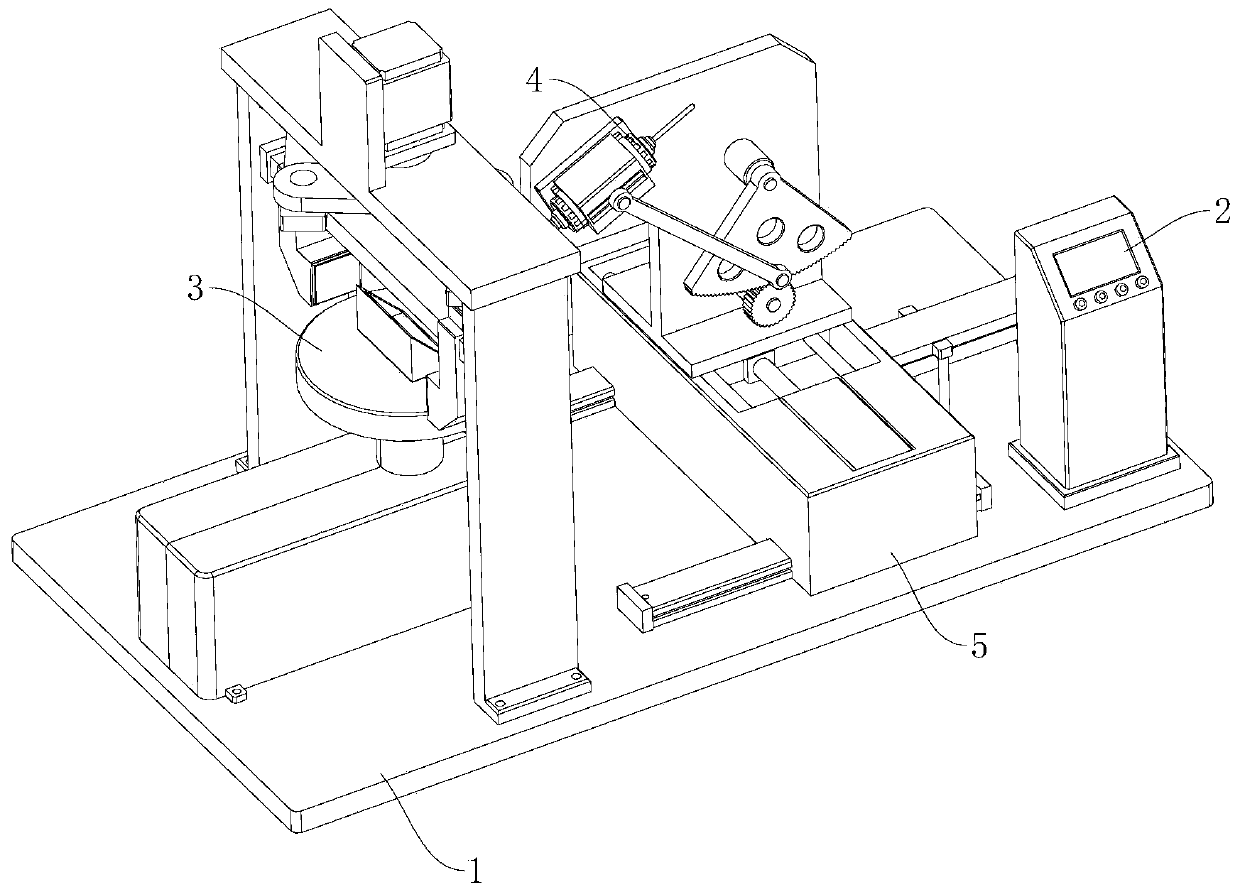

Aluminum alloy corner-wrapping block machining equipment and machining method

InactiveCN111283434APrevent being pinched or even pinchedPrevent slippingOther manufacturing equipments/toolsMetal machiningMaterials science

The invention relates to the technical field of metal machining, in particular to aluminum alloy corner-wrapping block machining equipment and machining method. The aluminum alloy corner-wrapping block machining equipment comprises a base and further comprises a controller, a fixing mechanism, a machining mechanism and a sliding mechanism, wherein the fixing mechanism comprises a supporting frame,a machining table, a clamping assembly and a first angle adjusting assembly, the sliding mechanism comprises a pushing assembly and a sliding assembly, the machining mechanism comprises a supportingplate, a grinding assembly, a drilling assembly and a second angle adjusting assembly, and the clamping assembly, the first angle adjusting assembly, the pushing assembly, the sliding assembly, the grinding assembly, the drilling assembly and the second angle adjusting assembly are all electrically connected with the controller. According to the aluminum alloy corner-wrapping block machining equipment and machining method, aluminum alloy corner-wrapping block grinding and drilling procedures can be alternately carried out without being sequentially carried out step by step, the working efficiency is improved, and meanwhile, aluminum alloy corner-wrapping blocks with different sizes can be machined, workers can be prevented from making contact with the machining table frequently, and potential safety hazards are effectively reduced.

Owner:朱明德

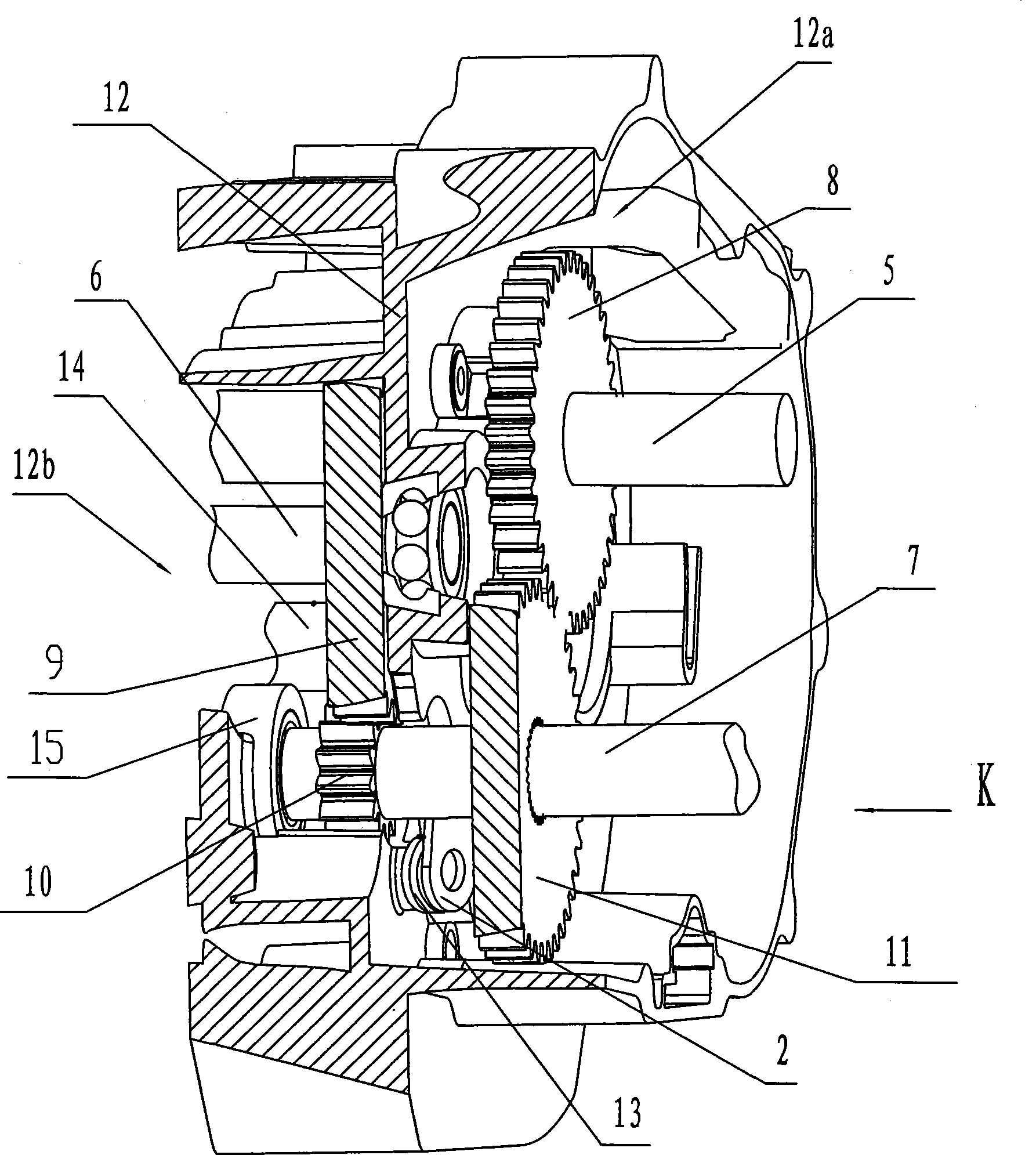

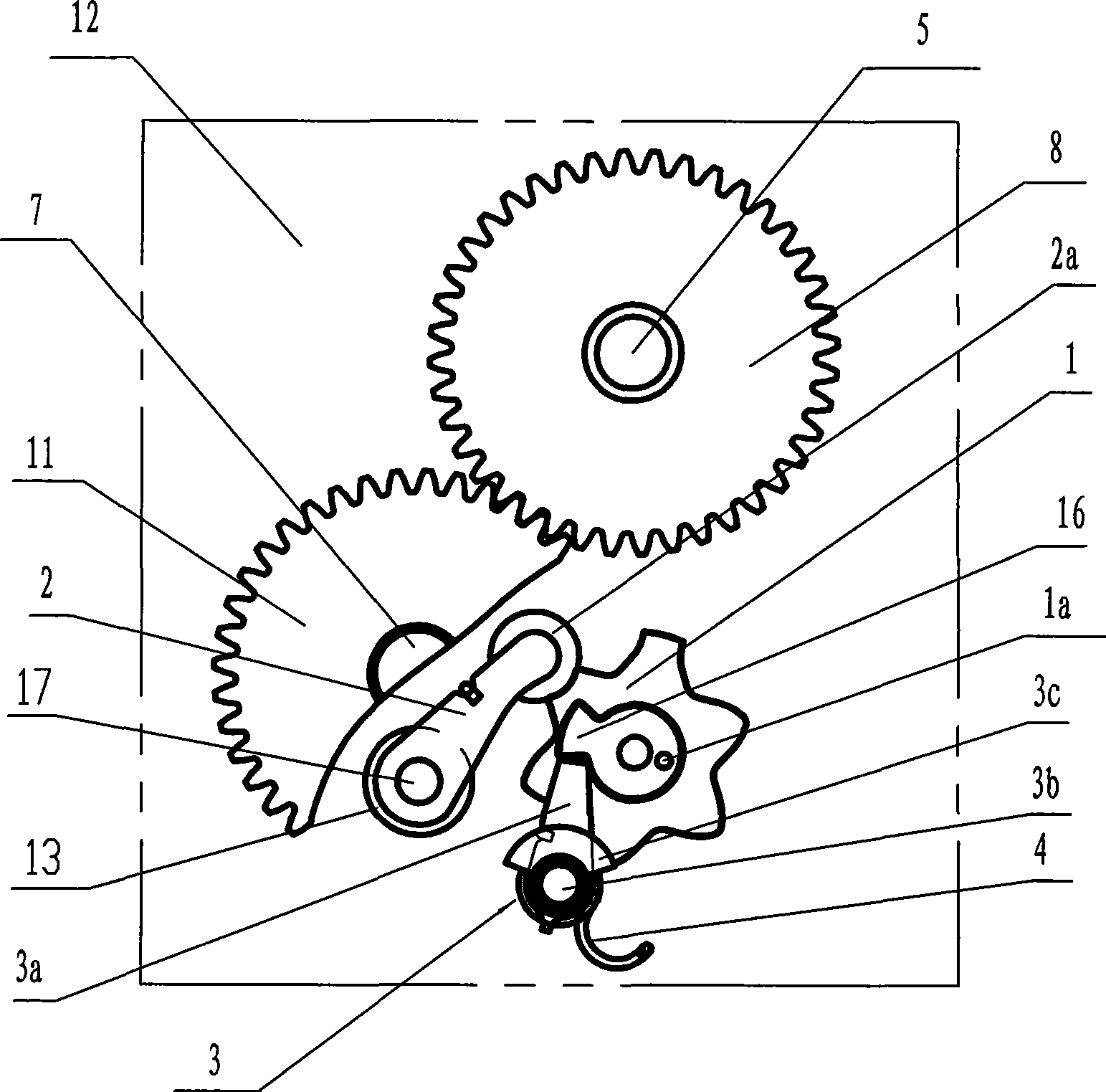

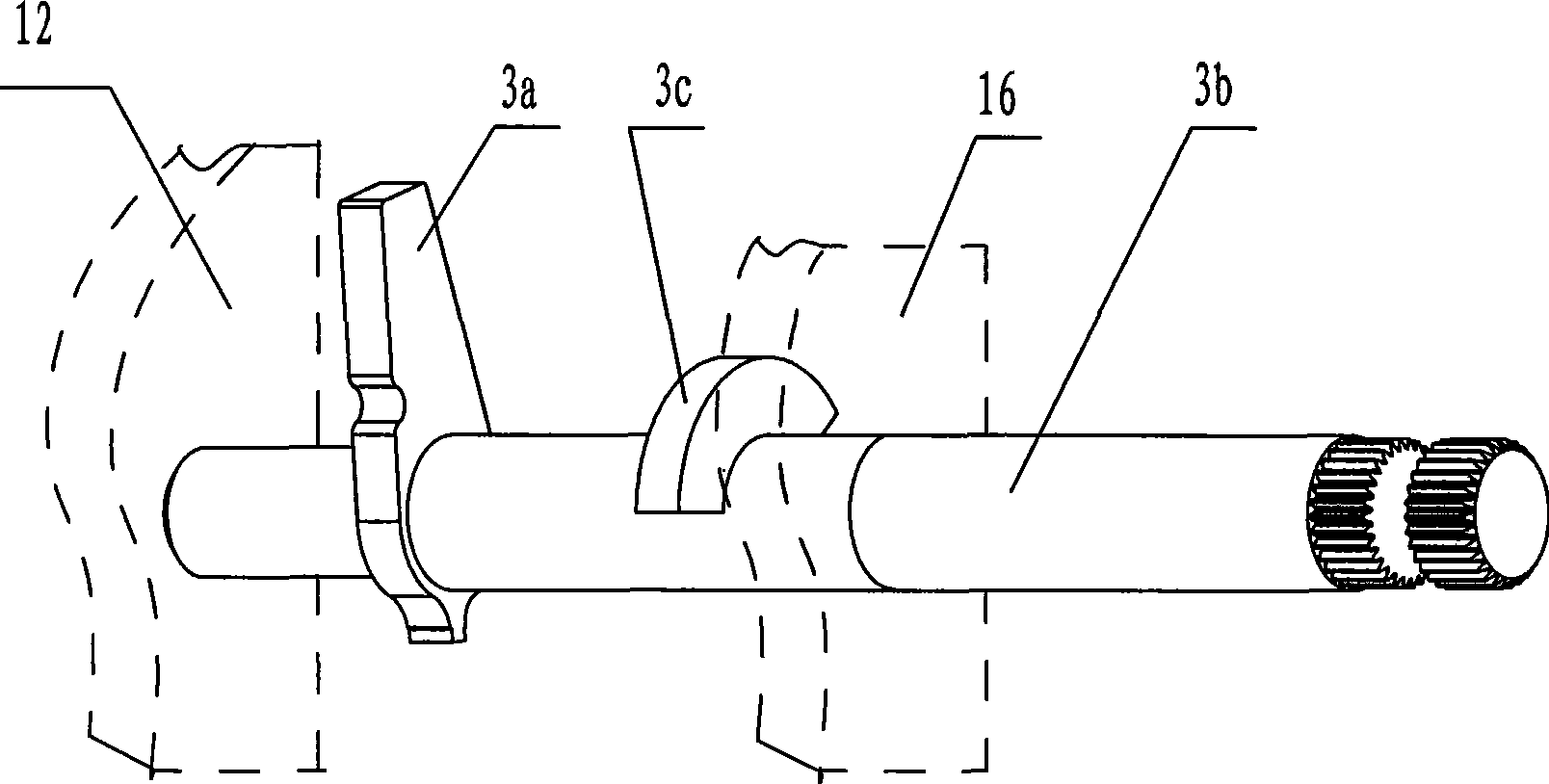

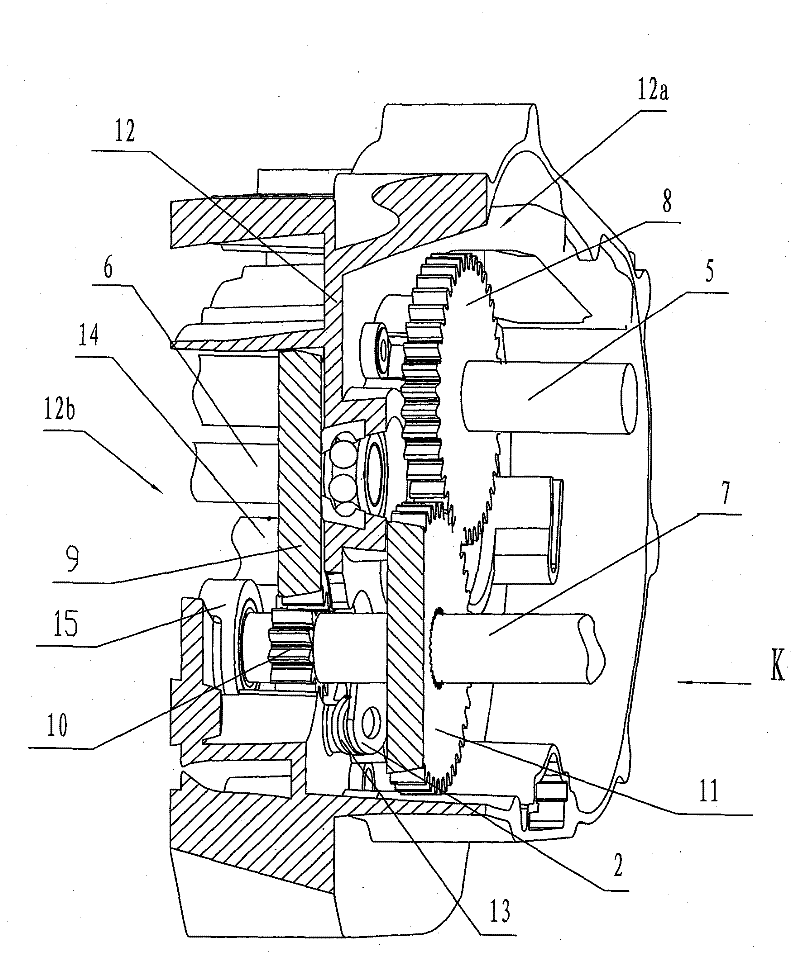

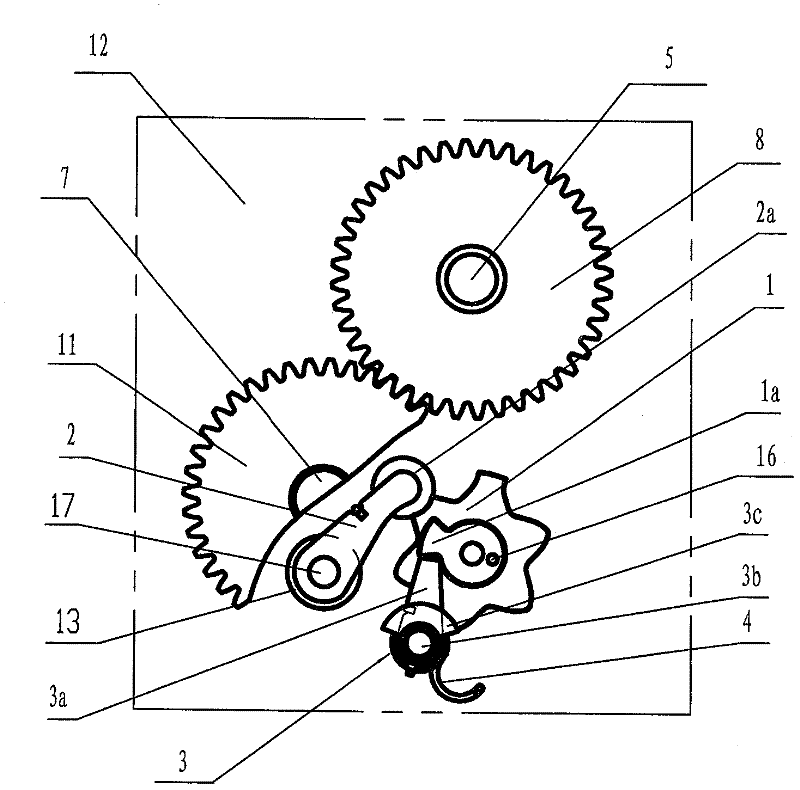

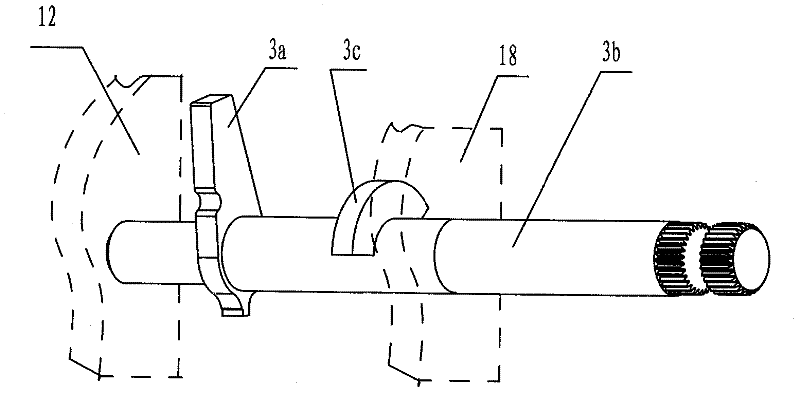

Reverse gear apparatus of motorcycle engine speed variator

The invention discloses a gear reversing device for motorcycle engine transmission. The input end of a main shaft of a transmission in a crankcase passes through a right crankcase and fixes a reverse driving gear on the cover-closing side of the right crankcase in the circumferential direction; a reverse gear is fixed on a countershaft of the transmission in the circumferential direction; the cover-closing side of the right crankcase is provided with an intermediate gear mechanism; a first gear of the intermediate gear mechanism meshes with the reverse driving gear on the main shaft; a second gear is corresponding to the reverse gear on the countershaft; a limit boss for preventing from entering reverse gear is arranged on the end face of a star-shaped shift wheel; and the cover-closing side of the right crankcase is provided with a reverse gear protection mechanism in constant contact with the limit boss on the star-shaped shift wheel. As the gear reversing device and the reverse gear protection mechanism are arranged by utilizing a vacant space between the cover-closing side of the crankcase and a cover of the crankcase, the arrangement of the reverse gear can be realized in a compact-structure motorcycle engine without increasing the size of the prior motorcycle engine crankcase, so as to reduce the cost for producing the motorcycle engine with a built-in reverse gear.

Owner:重庆东本工业有限责任公司

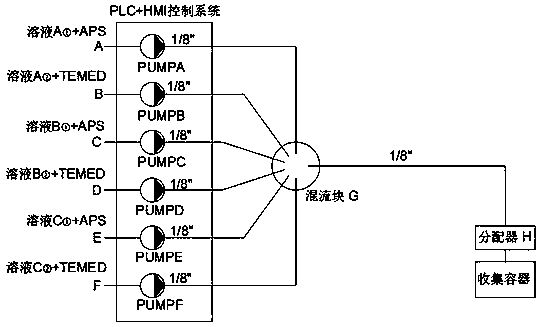

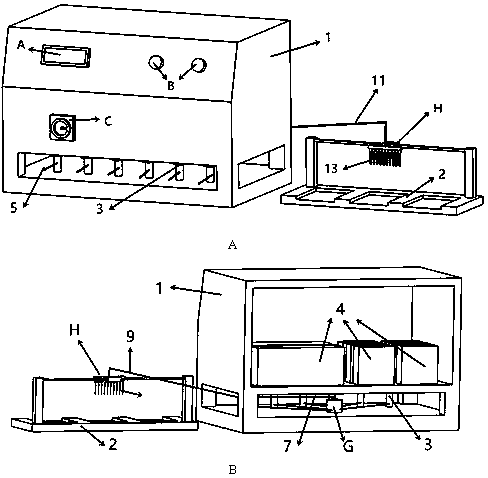

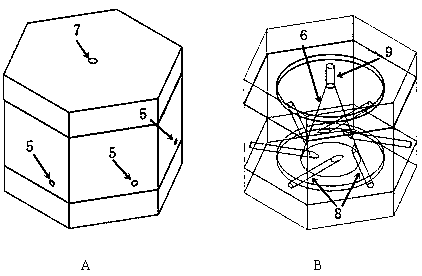

Fully automatic control glue pouring system and method for continuous production of gradient gel films

ActiveCN107128864BSolve the problem of clogged system pipingAvoid distortionLiquid fillingMixersState of artAutomatic control

The invention discloses a fully automatic control glue pouring system for continuous production of gradient gel films, comprising: several precision constant flow pumps, a PLC+HMI control system for controlling the precision constant flow pumps, a mixed flow block, and a distributor and a collection container; one end of the precision constant flow pump is a solution inlet, and the solution outlet at the other end is connected to the mixed flow block; two solutions of different concentrations are added with APS and TEMED, respectively, and enter the solution inlets of the two precision constant flow pumps; The flow mixing block is connected to the distributor, and the distributor is connected to the collection container. In addition, the invention also provides the usage method of the system. The invention solves the technical problems of continuity, precision and automatic control existing in the prior art.

Owner:安徽昊拓生物科技有限公司

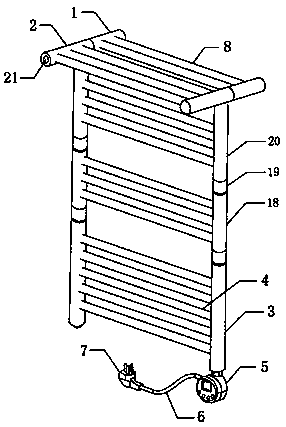

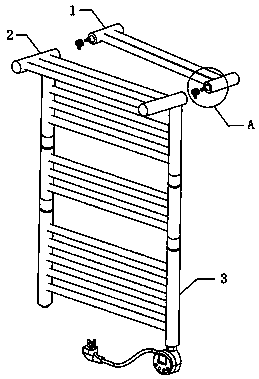

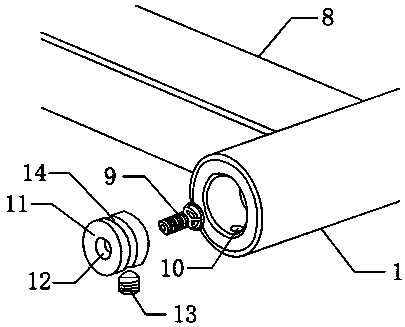

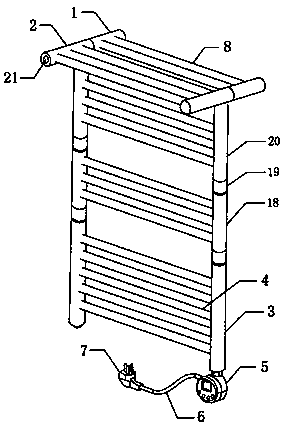

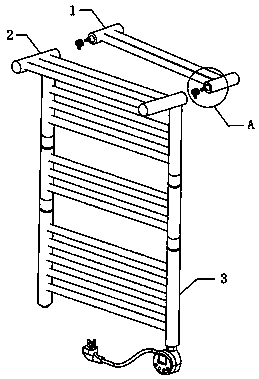

Removable intelligent temperature control type drying frame

ActiveCN108708146AImprove usabilityImprove practicalityTextiles and paperLaundry driersElectric heatingScalding

The invention discloses a removable intelligent temperature control type drying frame which comprises a fixed tube, a mounting tube, a first vertical tube, a second vertical tube and at least one middle vertical tube. An electric heating tube is mounted inside the first vertical tube, a temperature controller is mounted at the bottom of the first vertical tube, and an infrared induction switch isfixedly mounted on the lower portion of the temperature controller. The middle vertical tubes are mounted at the upper end of the first vertical tube through threaded sleeves, the second vertical tubeis mounted at the upper ends of the middle vertical tubes through threaded sleeves, the threaded sleeves are used for detachably mounting the middle vertical tubes with different lengths or heights or mounting the middle vertical tubes in a freely combined manner, the upper end of the second vertical tube is communicated with the mounting tube, and a fixed block is mounted at one end of the mounting tube through a bolt, inserted into one end of the fixed tube and fixed by a glass bead screw. The drying frame can be freely removed and extended and is strong in practicability, non-contact control can be performed, and scalding is decreased.

Owner:JIANGXI AVONFLOW HVAC TECH CO LTD

Sock sublimation transfer printing machine

The invention relates to a sock sublimation transfer printing machine. The sock sublimation transfer printing machine comprises a rack, wherein a main conveying mechanism is mounted on a support panel of the rack; a U-shaped box is fixedly mounted on the upper part of the rack; a paper conveying system and a deviation rectifying device are mounted on the side wall of the U-shaped box; a sublimation transfer printing device is mounted on the rack and the U-shaped box. According to the sock sublimation transfer printing machine, the socks are artificially loaded and unloaded; due to the cooperation of the main conveying mechanism, the paper conveying mechanism, the deviation rectifying device and the sublimation transfer printing device, the pattern alignment accuracy is greatly improved; the sublimation transfer printing time is reduced; the production efficiency is improved; the mechanization level and the level automation of the industry are promoted to higher levels.

Owner:JIANGNAN UNIV

A high-efficiency automatic square tank production line

ActiveCN105562546BAutomate operationSolve the clamping problemMetal-working feeding devicesStripping-off devicesProduction lineComputer module

The invention discloses a high-efficiency automatic square tank production line. The high-efficiency automatic square tank production line comprises a forming device, a loading device, a conveying device module I, a conveying device module II, a conveying device module III, a machining device, an unloading device and a control box. The loading device and the unloading device are arranged on the front and back sides of a conveying device in parallel to realize automatic loading and unloading of square tanks. The conveying device module I, the conveying device module II and the conveying device module III are positioned between left and right stand columns of the machining device to realize conveying of the square tanks; and the machining device clamps the square tanks. The machining device is positioned in the middle of the production line; a main shaft part of the machining device can realize high-efficiency machining of the tanks; and the control box is positioned in a production line welding box to control operation of the production line. The high-efficiency automatic square tank production line realizes forming, loading / unloading, conveying, clamping and machining automation of the square tanks based on a mechanical-electrical integration principle, simplifies the machining process, improves the production efficiency, can reduce the worker number, and reduces the potential safety hazard in the production process.

Owner:TAIZHOU LANYI INTELLIGENT EQUIP TECH CO LTD

Vertical pneumatic bending, flavoring and feeding device

The invention discloses a vertical pneumatic bending, flavoring and feeding device. The device comprises a tobacco feed hopper, a main working cylinder, a flavoring and feeding nozzle, a bracket and a pipeline of the flavoring and feeding nozzle, a warming and humidifying nozzle, a bracket and a pipeline of the warming and humidifying nozzle, a tobacco filter screen, a feed liquid filter core, a hot air circulating system, a hot air pipeline of the hot air circulating system, an air-distributing system and a discharge gate, wherein the air-distributing system consists of a conical air-distributing plate, a periphery airflow air supply pipeline, a periphery airflow chamber, a central airflow air supply pipeline, a central airflow pipeline and a center hole plate; the feed hopper is positioned on a side wall of the main working cylinder; and the tobacco filter screen, the flavoring and feeding nozzle, the bracket and the pipeline of the flavoring and feeding nozzle, the warming and humidifying nozzle and the bracket and the pipeline of the warming and humidifying nozzle are sequentially arranged from top to bottom in the main working cylinder. In the device, tobaccos violently rotate and tumble in the cylinder under the action of two airflows of a bottom center hole plate and a conical hole plate having spiral holes; the flavoring and feeding nozzle performs flavoring and feeding on the tobaccos in violent motion; and the applied feed liquid is more uniform.

Owner:NANJING UNIV OF SCI & TECH +1

Circuit board mounting device

ActiveCN112601384AAvoid pollutionSolve technical problems of pollutionPrinted circuit assemblingCircuit board tools positioningStructural engineeringTransfer line

The invention discloses a circuit board mounting device. The device comprises a pedestal which is provided with a feeding assembly, a conveying assembly, a carrying assembly, and a stacking assembly,wherein a jacking part is arranged in the feeding assembly and used for jacking upwards in the Z-axis direction; the conveying assembly is arranged on the side face of the feeding assembly and provided with a conveying line in the X-axis direction; the carrying assembly is arranged on one side of the feeding assembly, the carrying assembly is provided with a suction part, and the suction part is used for moving from the position above the jacking part to the position above the conveying line in the Y-axis direction; the stacking assembly is arranged on the side, away from the carrying assembly, of the conveying assembly. According to the circuit board mounting device, a problem that in the prior art, in the process that a PCB is manually inserted into an SMT feeding and discharging frame,the PCB makes frequent contact with a human body, and consequently pollution to the PCB is increased is solved, pollution of human factors to the PCB in the PCB inserting process is avoided, the finished product rate and the conversion rate in subsequent production are effectively increased, and the cost is reduced.

Owner:TCL KING ELECTRICAL APPLIANCES HUIZHOU

Novel intelligent tape unit and data processing method

InactiveCN100578650CReduce seek timeIncreased durabilityRecord information storageDigital storageMemory chipElectricity

The invention discloses a novel intelligent tape driver and a data processing method thereof, belonging to a chip-tape storage device and a data processing method thereof, which comprises a memory chip arranged inside a tape cassette and an interface circuit thereof, and a memory chip read-write module arranged on the tape driver and an interface circuit thereof, wherein, the two interface circuits are electrically connected by a pair of metal contacts. The tape driver processor is connected with the memory chip through an interface circuit after being connected with the memory chip read-write module. Only a data area is arranged on the tape. The memory chip is divided into an index mark section, a writing cache, a read cache and other data section, wherein, both reading and writing requests of data are performed in the reading and writing caches, other than in the tape driver. The combination of the sequential memory of the tape and the random memory of the chip reduces the frequent mechanical motion of the tape driver, thereby improving the retrieval speed and the memory efficiency and prolonging the service life of the tape driver.

Owner:WISESOFT CO LTD +1

A detachable intelligent temperature-controlled drying rack

ActiveCN108708146BEasy to useImprove and increase usabilityTextiles and paperLaundry driersVertical tubeTemperature control

The invention discloses a removable intelligent temperature control type drying frame which comprises a fixed tube, a mounting tube, a first vertical tube, a second vertical tube and at least one middle vertical tube. An electric heating tube is mounted inside the first vertical tube, a temperature controller is mounted at the bottom of the first vertical tube, and an infrared induction switch isfixedly mounted on the lower portion of the temperature controller. The middle vertical tubes are mounted at the upper end of the first vertical tube through threaded sleeves, the second vertical tubeis mounted at the upper ends of the middle vertical tubes through threaded sleeves, the threaded sleeves are used for detachably mounting the middle vertical tubes with different lengths or heights or mounting the middle vertical tubes in a freely combined manner, the upper end of the second vertical tube is communicated with the mounting tube, and a fixed block is mounted at one end of the mounting tube through a bolt, inserted into one end of the fixed tube and fixed by a glass bead screw. The drying frame can be freely removed and extended and is strong in practicability, non-contact control can be performed, and scalding is decreased.

Owner:JIANGXI AVONFLOW HVAC TECH CO LTD

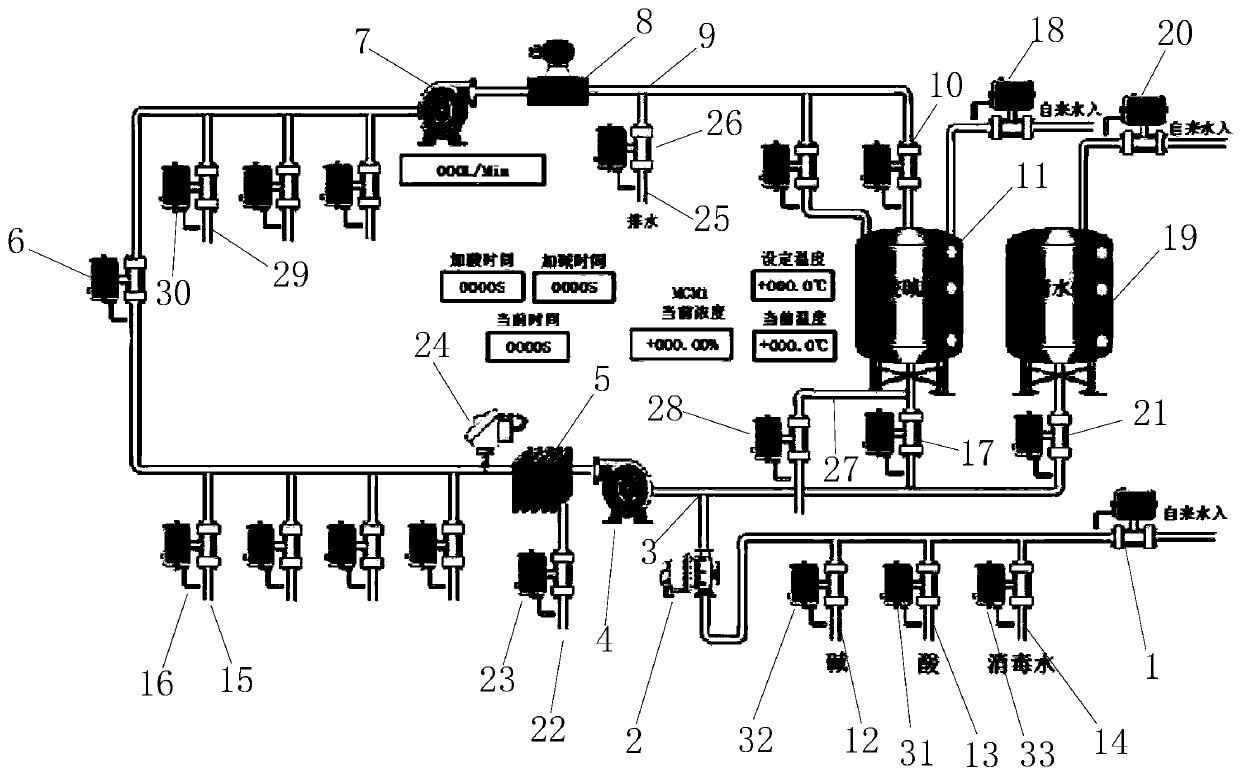

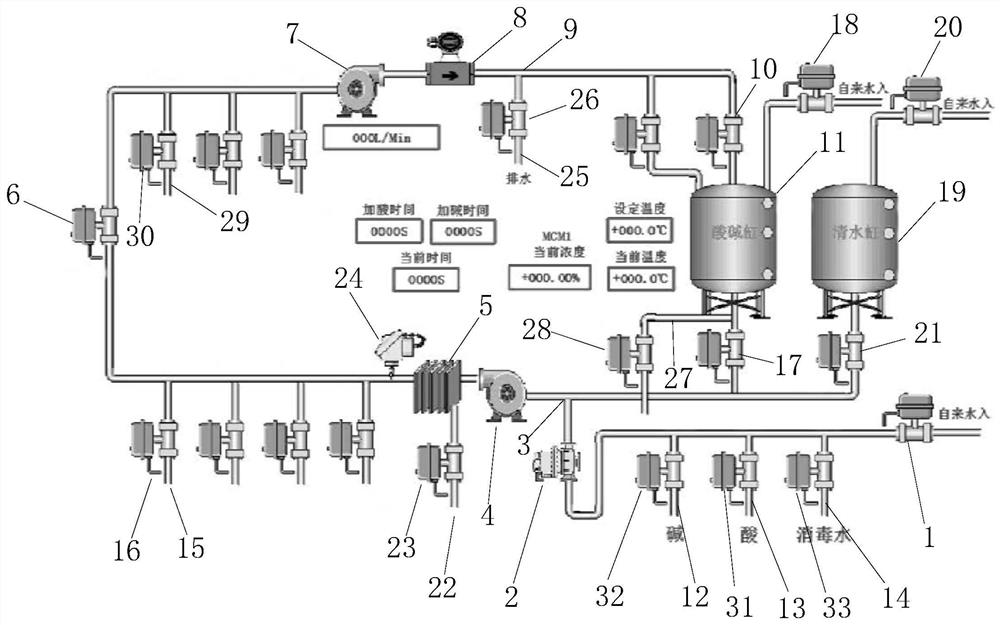

Cleaning control system and method thereof

ActiveCN111014192AShorten cleaning timeImprove cleaning efficiencyHollow article cleaningAlkaline waterAcid water

The invention relates to a cleaning control system and a method thereof, and belongs to the technical field of cleaning. The method comprises five steps of hot water cleaning, alkaline water cleaning,acid water cleaning, clear water cleaning and disinfection water cleaning. The method has the advantages of preventing personnel from contacting chemicals frequently, stabilizing CIP water concentration control for cleaning, shortening cleaning time, improving cleaning efficiency and improving automatic control operation of equipment.

Owner:李锦记(广州)食品有限公司

A cleaning control system and method thereof

ActiveCN111014192BAvoid frequent contactStable cleaningHollow article cleaningAlkaline waterAcid water

The invention relates to a cleaning control system and a method thereof, belonging to the technical field of cleaning. It includes five steps of hot water cleaning, alkaline water cleaning, acid water cleaning, clear water cleaning and disinfectant water cleaning. It has the advantages of eliminating frequent contact of personnel with chemicals, stabilizing the control of CIP water concentration, reducing cleaning time, improving cleaning efficiency and improving automatic control operation of equipment.

Owner:李锦记(广州)食品有限公司

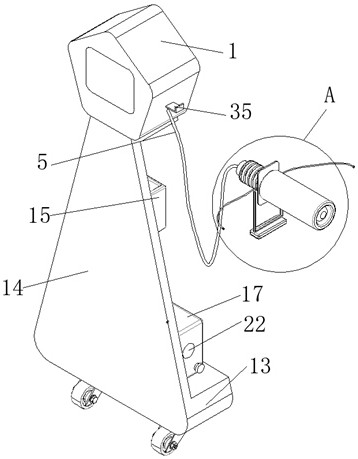

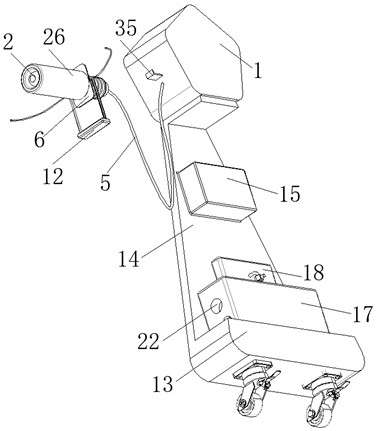

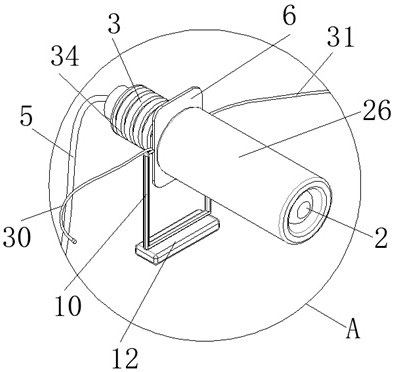

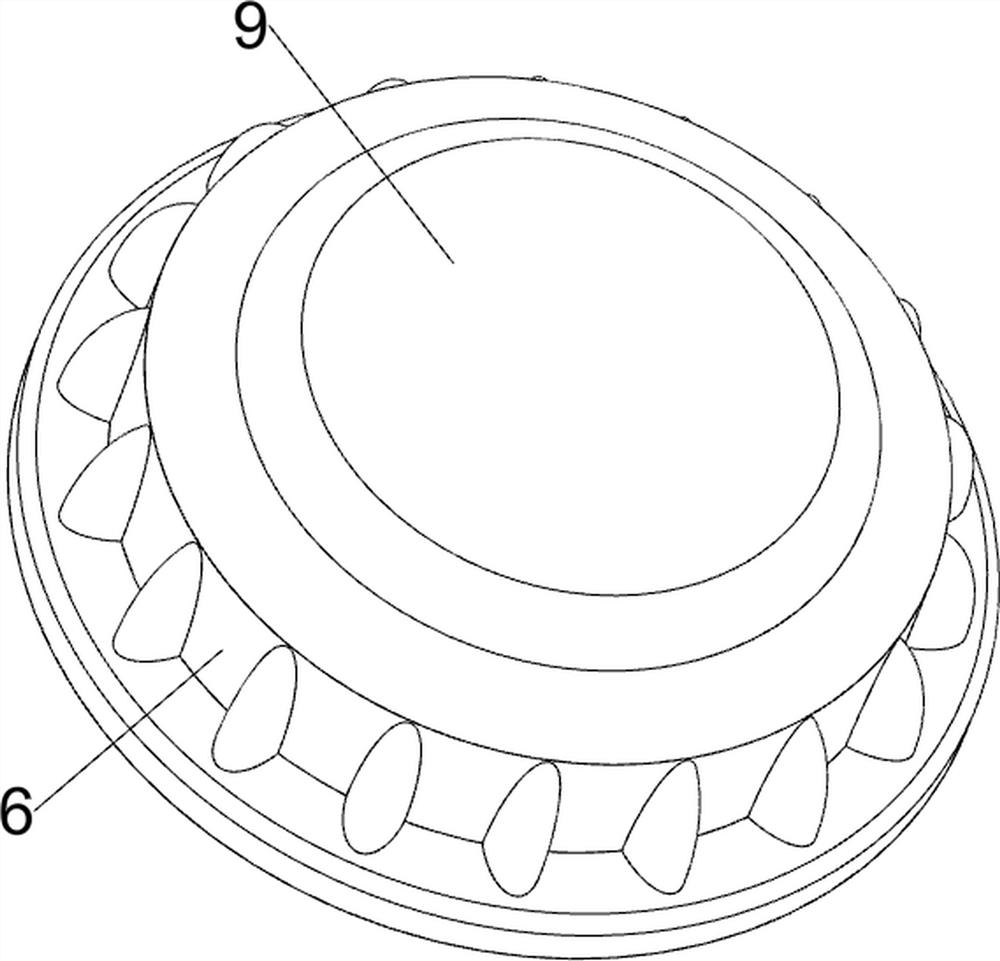

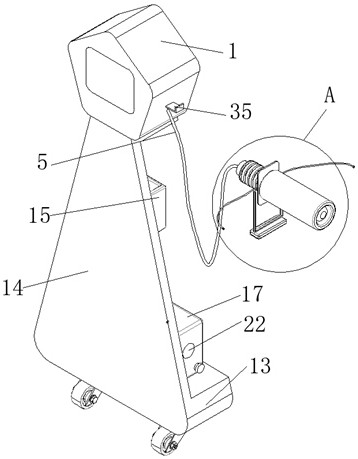

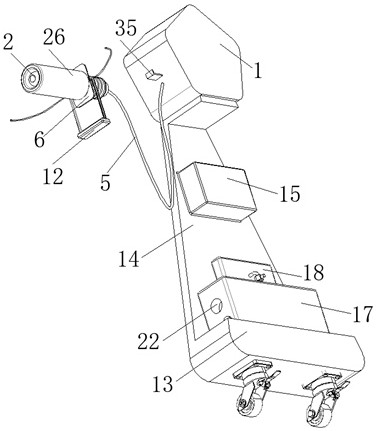

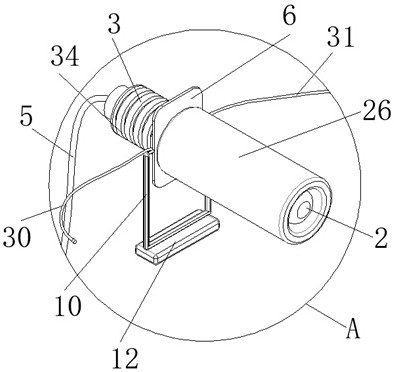

Female private firming young state ultrasonic knife treatment system

ActiveCN113058169ARelieve painAvoid frequent contactUltrasound therapyLavatory sanitoryEngineeringMechanical engineering

The invention discloses a female private firming young state ultrasonic knife treatment system, which comprises a main body structure, the main body structure comprises a treatment instrument, wherein one side of the treatment instrument is communicated with a wire, one end, far away from the treatment instrument, of the wire is communicated with an ultrasonic transducer, and the two sides of the outer wall of the ultrasonic transducer are provided with emission windows; and a fixing structure which comprises a fixing plate, wherein the outer side of the fixing plate is fixedly connected with an annular sleeve plate, before treatment, the air bag is inserted into the vagina, the air bag is inflated, the vagina is slowly expanded, then air in the second cavity close to the inner diameter of the air bag is pumped away, meanwhile, the fixing structure is arranged in the air bag in a sleeved mode, and the ultrasonic transducer is sleeved with the fixing structure, frequent contact between the ultrasonic transducer and the vagina is avoided when the ultrasonic transducer rotates or is pulled away, then gas in the first cavity is pulled away, a patient gradually adapts to the fixing structure, and the pain of the patient is relieved.

Owner:武汉真爱妇产医院有限公司

Start-free self-partition convenient kit

PendingCN114291405AEasy accessEliminates the step of pushing back into placeDispensing apparatusDischarging meansStructural engineeringMechanical engineering

The invention relates to the field of kits, in particular to an opening-free self-partition convenient kit. The technical problems that a box cover needs to be opened, then a reagent bottle is buckled out of a placing plate, and the operation process is tedious; in the frequent taking process of reagents, the kit needs to be in contact with the external air environment for many times, so that external bacteria and viruses easily enter the kit body. According to the technical scheme, the opening-free self-partition convenient kit comprises a kit body, an opening cover, a fixing buckle and the like; the upper rear side of the box body is movably connected with an opening cover; a fixing buckle is installed in the middle of the front side of the opening cover, and a clamping groove matched with the fixing buckle is formed in the upper portion of the front side of the box body. When the reagent box is used, the reagent box does not need to be opened in the reagent taking process, the reagent containing plate and the reagents are automatically pushed out, automatic cutting is conducted according to the number of the needed reagents, taking and using are convenient, and the step that reagent bottles are manually taken out of the containing plate and then the containing plate is pushed back to the original position is omitted.

Owner:刘建华

A cookie storage box

ActiveCN105730842BEasy accessAvoid frequent contactDischarging meansPackaging bakeryEngineeringFood packaging

Owner:邳州市铁富九龙公共服务有限公司

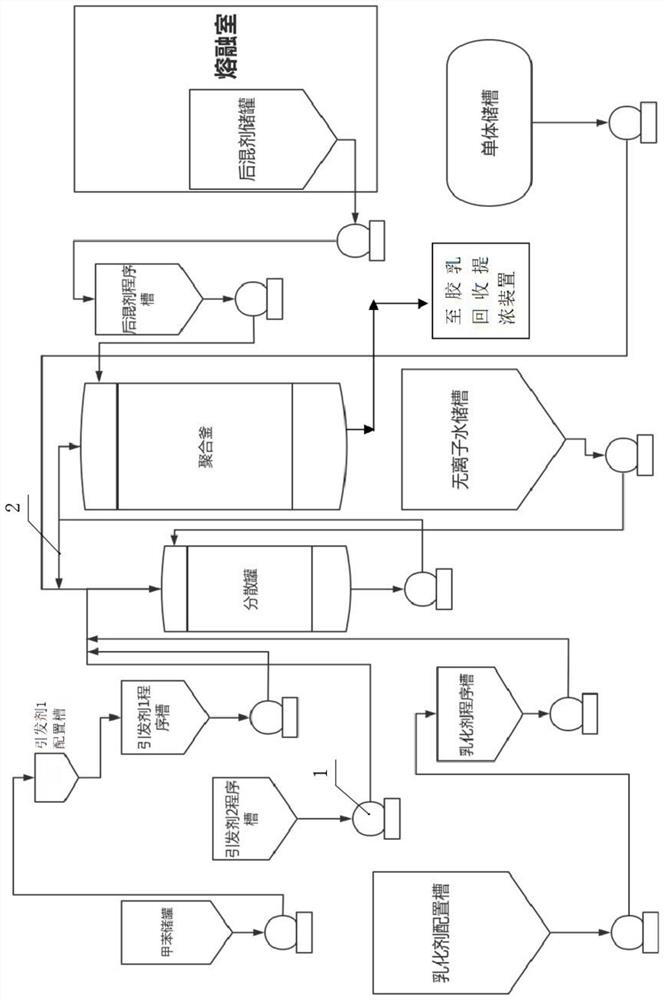

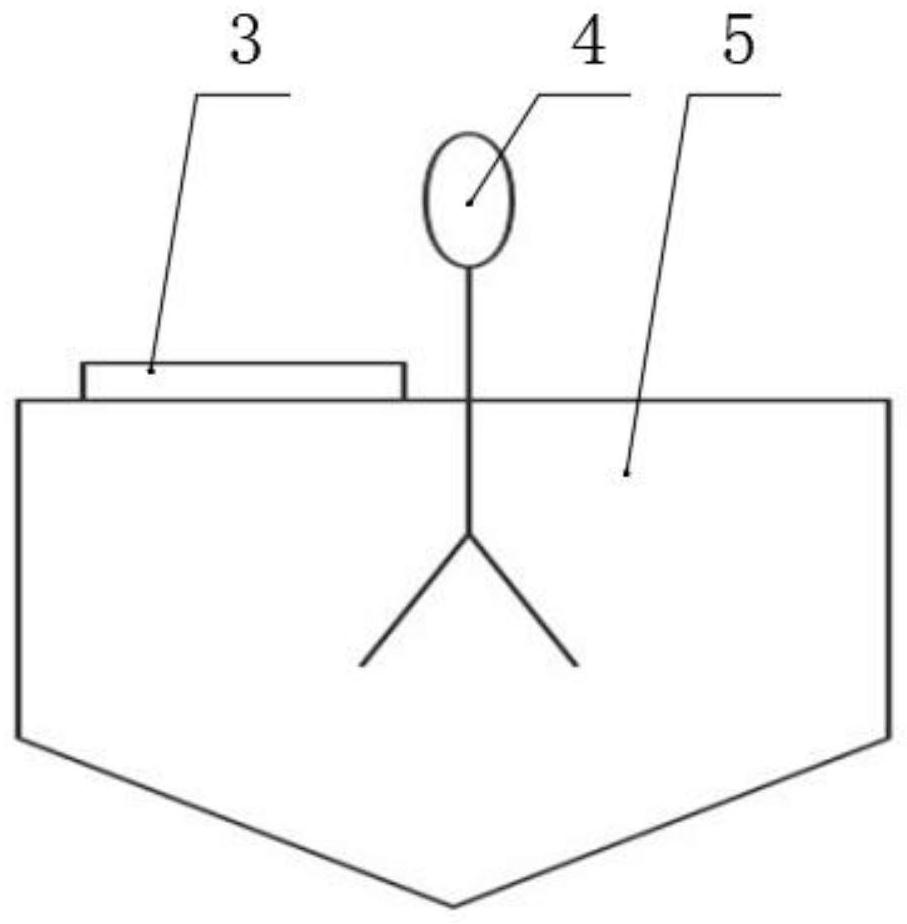

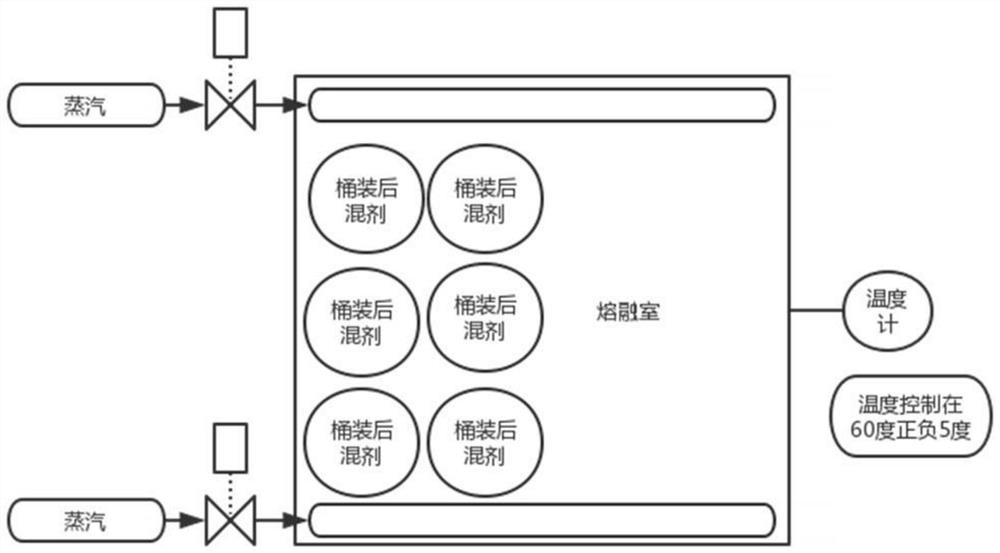

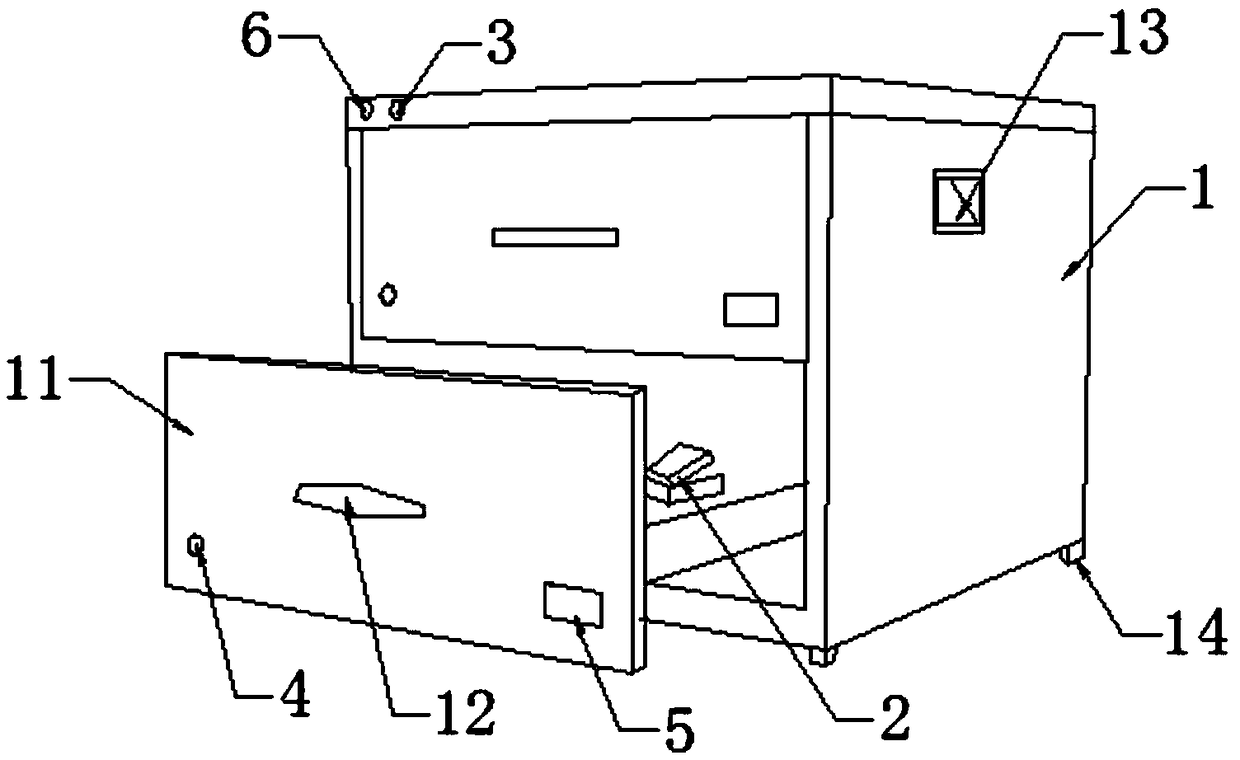

Polyvinyl chloride paste resin micro-suspension polymerization method

ActiveCN113136000AImprove accuracyReduce intensityHollow article cleaningWater storage tankPolyvinyl chloride

The invention provides a polyvinyl chloride paste resin micro-suspension polymerization method. Equipment used in the polymerization process comprises a polymerization kettle, a dispersion tank, a toluene storage tank, an initiator 1 preparation tank, an initiator 1 program tank, an emulsifier program tank, a deionized water storage tank, a monomer storage tank and a post-mixing agent program tank. The input end of the polymerization kettle is communicated with the output end of the dispersion tank, the input end of the dispersion tank is respectively communicated with the initiator 1 program tank, the initiator 2 program tank, the emulsifier program tank, the deionized water storage tank and the monomer storage tank, and the post-mixing agent program tank is communicated with the polymerization kettle; and the initiator 1 program tank is communicated with the initiator 1 configuration tank, and the initiator 1 configuration tank is communicated with the methylbenzene storage tank. According to the invention, the addition of the preparation, the flushing of the polymerization kettle and the recovery of the monomer are all automatically completed, and the whole process is high in automation degree and high in production efficiency, and has great advantages in the aspects of energy consumption, monomer residual quantity, yield and the like.

Owner:天津市滨海新区众友缘科技发展有限公司

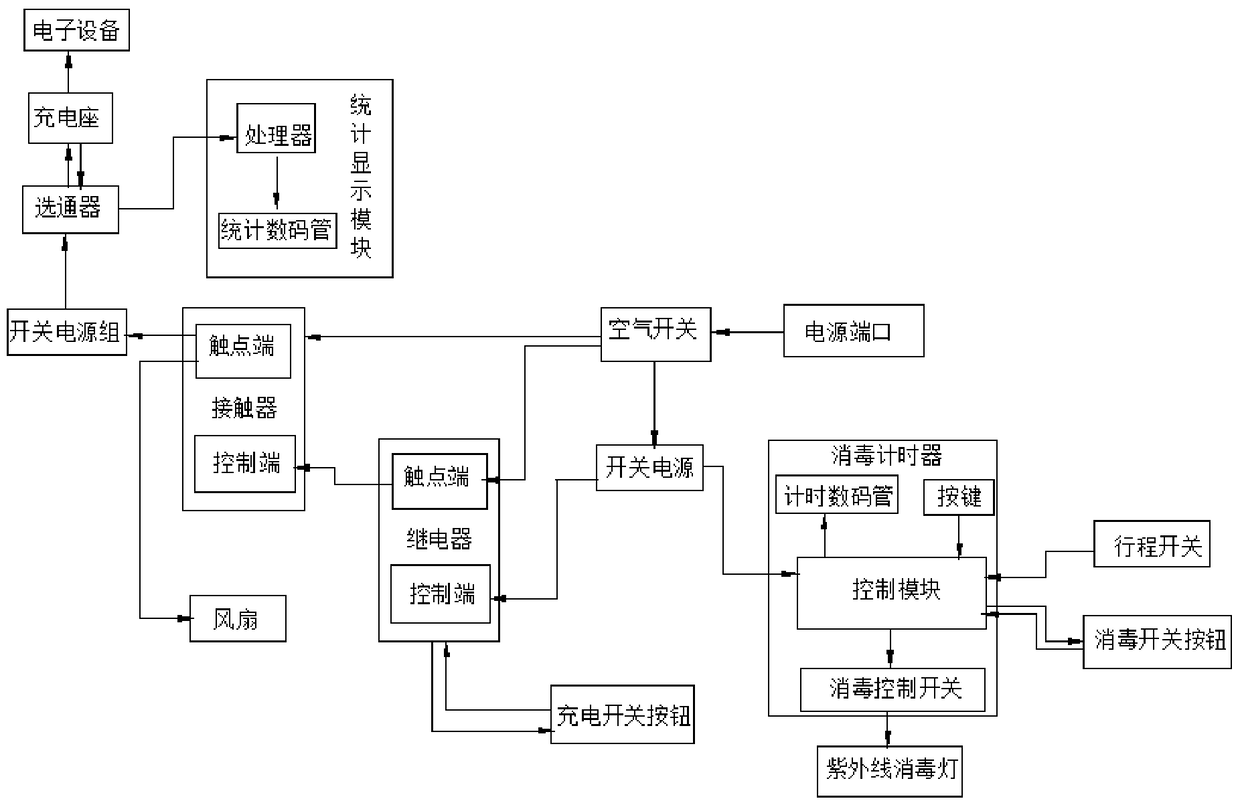

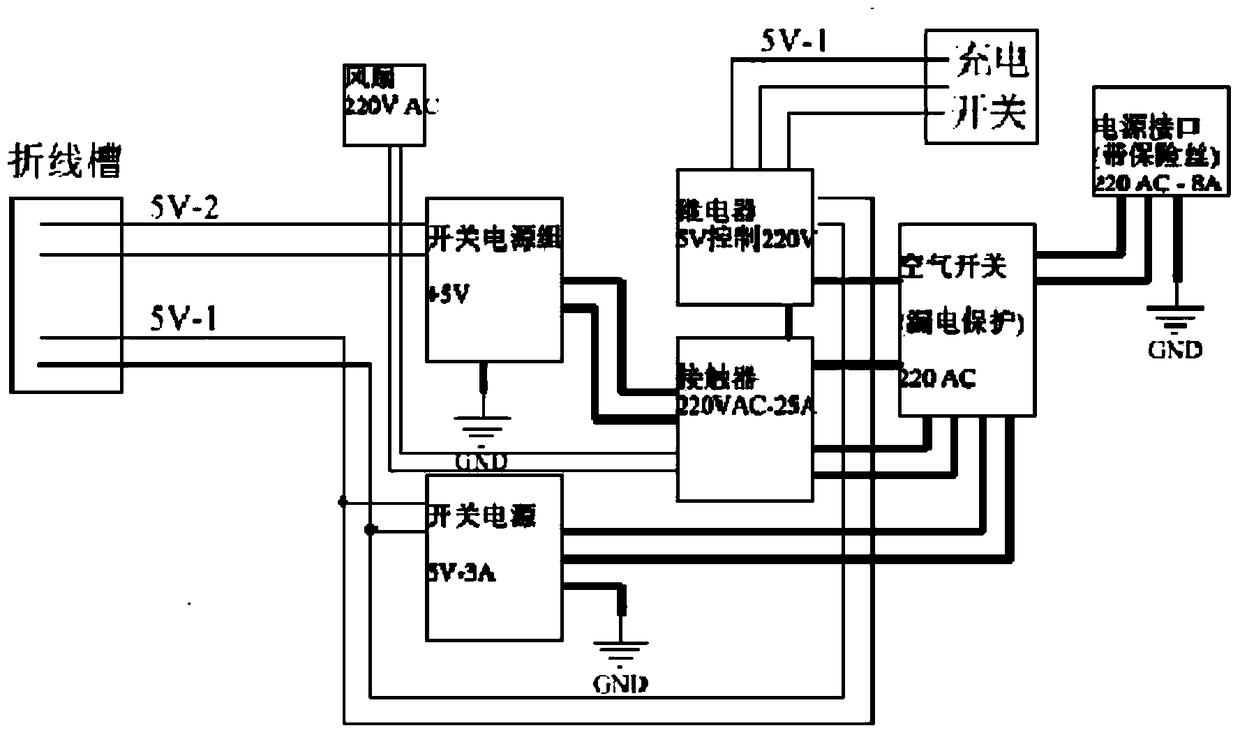

A charging disinfection cabinet with safety protection function

ActiveCN105467883BEnsure safetyImprove securityArrangements responsive to excess currentProgramme control in sequence/logic controllersElectricityMultiplexer

The invention provides a charging disinfector with a safety protection function, which comprises a cabinet body and a power port, an air switch, a switching power supply, a switching power supply group, a multiplexer, charging seats, a limit switch, a disinfection timer, a disinfection switch button and an ultraviolet disinfection lamp arranged inside the cabinet body, wherein the power port is fixed on the side wall of the cabinet body; the power port outputs two ways of power lines via the air switch, one path is connected into the switching power supply and the other path is connected into the switching power supply group; the switching power supply group is electrically connected with the multiplexer, a power signal is inputted to the multiplexer, and multiple charging seats are correspondingly connected onto the multiplexer; the switching power supply is electrically connected with the ultraviolet disinfection lamp via the disinfection timer; and both the limit switch and the disinfection switch button are in signal connection with the disinfection timer. According to the charging disinfector with the safety protection function, through perfecting defects of the existing charging disinfector, the safety and the practicality of the charging disinfector are enhanced.

Owner:天津恒达文博科技股份有限公司

Reverse gear apparatus of motorcycle engine speed variator

InactiveCN101435491BAvoid damageWith reverse functionToothed gearingsGearing controlGear wheelProtection mechanism

The invention discloses a gear reversing device for motorcycle engine transmission. The input end of a main shaft of a transmission in a crankcase passes through a right crankcase and fixes a reverse driving gear on the cover-closing side of the right crankcase in the circumferential direction; a reverse gear is fixed on a countershaft of the transmission in the circumferential direction; the cover-closing side of the right crankcase is provided with an intermediate gear mechanism; a first gear of the intermediate gear mechanism meshes with the reverse driving gear on the main shaft; a second gear is corresponding to the reverse gear on the countershaft; a limit boss for preventing from entering reverse gear is arranged on the end face of a star-shaped shift wheel; and the cover-closing side of the right crankcase is provided with a reverse gear protection mechanism in constant contact with the limit boss on the star-shaped shift wheel. As the gear reversing device and the reverse gear protection mechanism are arranged by utilizing a vacant space between the cover-closing side of the crankcase and a cover of the crankcase, the arrangement of the reverse gear can be realized in a compact-structure motorcycle engine without increasing the size of the prior motorcycle engine crankcase, so as to reduce the cost for producing the motorcycle engine with a built-in reverse gear.

Owner:重庆东本工业有限责任公司

Ultrasonic scalpel treatment system for women's private, firm and youthful state

ActiveCN113058169BRelieve painAvoid frequent contactUltrasound therapyLavatory sanitoryEngineeringMechanical engineering

The invention discloses an ultrasonic scalpel treatment system for women's intimate, compact and youthful state, which includes a main structure, the main structure includes a therapeutic instrument, one side of the therapeutic instrument is connected with a wire, and the end of the conductive wire away from the therapeutic instrument is connected with a Ultrasonic transducer, both sides of the outer wall of the ultrasonic transducer are equipped with emission windows; fixed structure, the fixed structure includes a fixed plate, the outer side of the fixed plate is fixedly connected with an annular cover plate, the present invention, before treatment , the airbag is inserted into the vagina, inflated to the inside of the airbag, and the vagina is slowly expanded, and then the gas inside the second cavity close to the inner diameter of the airbag is drawn away, and the fixed structure is placed inside the airbag, and the fixed structure is placed on the ultrasonic transducer. The outer side of the transducer, the ultrasonic transducer is rotated or pulled away to avoid frequent contact with the vagina, and then the gas inside the first cavity is pulled away, so that the patient gradually adapts to the fixed structure and relieves the pain of the patient.

Owner:武汉真爱妇产医院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com