Reverse gear apparatus of motorcycle engine speed variator

An engine and transmission technology, applied in the direction of transmission, gear transmission, transmission control, etc., can solve the problems of increasing enterprise investment, increasing the internal space size of crankcase, etc., to ensure the effect of shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

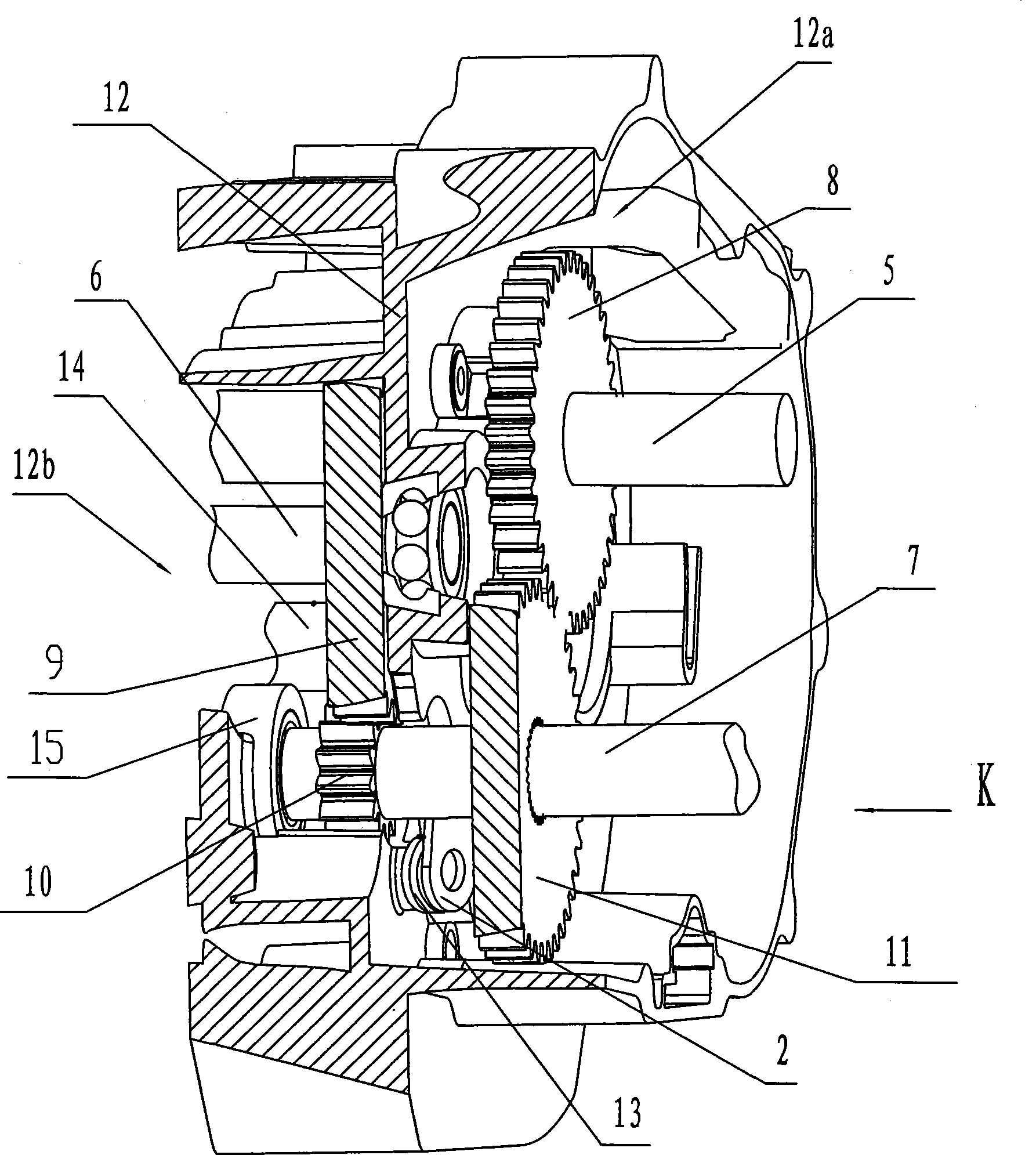

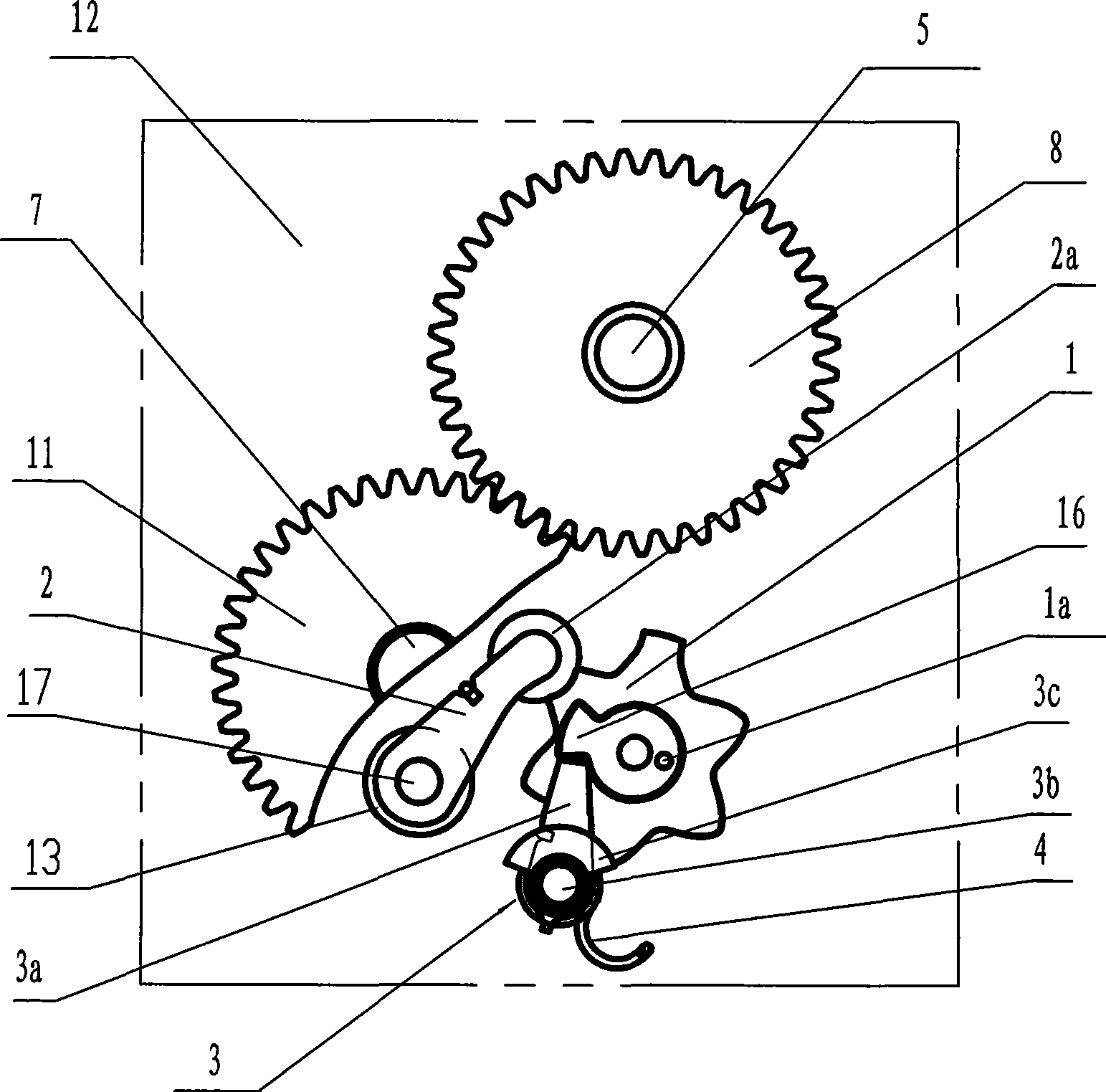

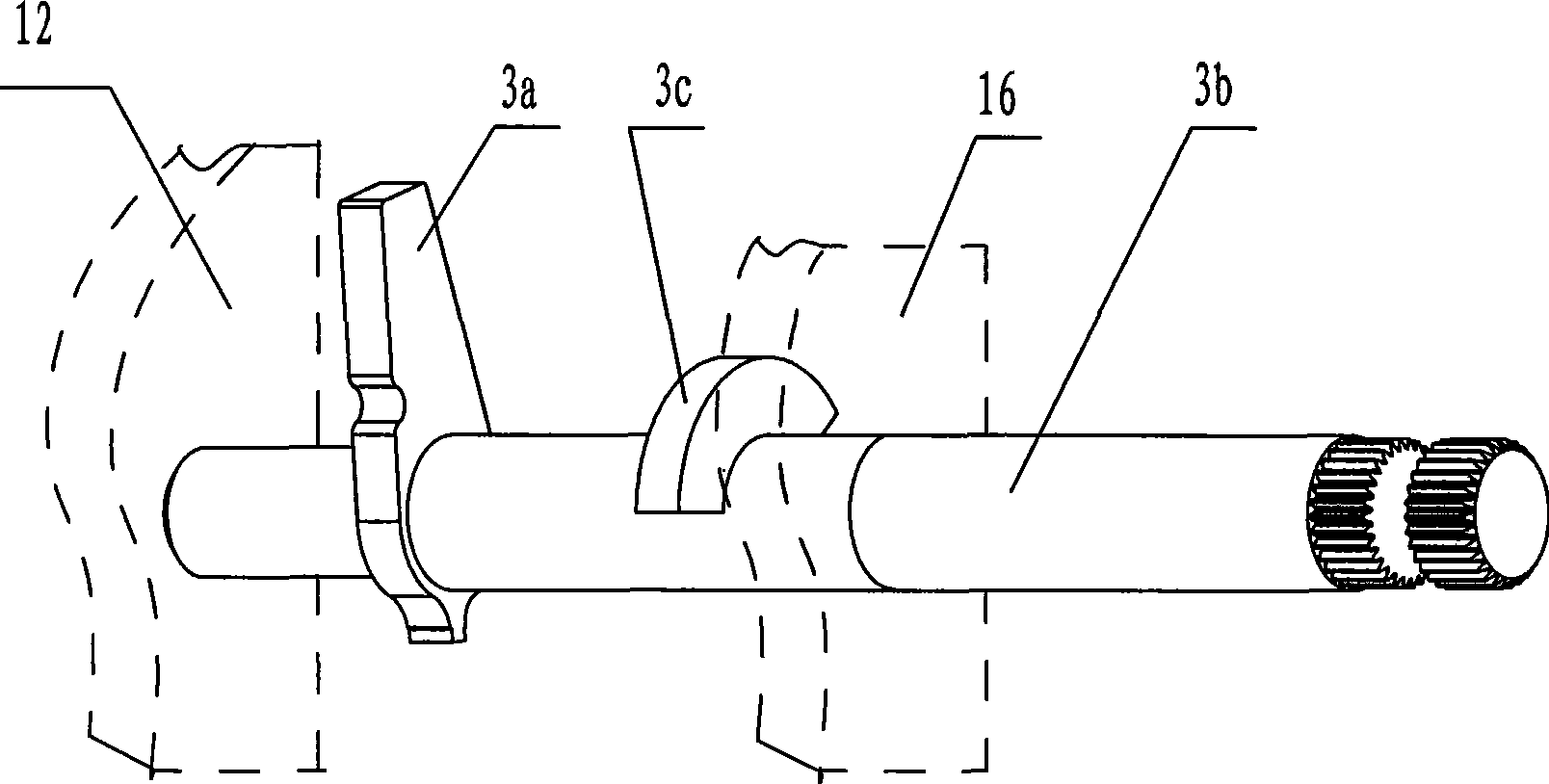

[0011] see Figure 1 to Figure 3 , a kind of embodiment of the reverse gear of motorcycle engine speed changer. The input end of the main shaft 5 of the speed changer in the crankcase passes through the right crankcase 12 and is connected with the clutch (not shown) at the cover side 12a of the right crankcase, and the shaft end of the speed change hub 14 in the crankcase passes through the right crankcase 12 in the crankcase. The cover side 12a of the right crankcase is threaded to the star gear wheel 1, and the star gear wheel 1 is circumferentially fixed with the transmission hub through the positioning pin 16, and the cover side 12a of the right crankcase is hinged with a screw 17 with a preload. The positioning block 2 presses the star-shaped gear wheel 1 to form a gear position. The screw 17 is covered with a torsion spring 13. One end of the torsion spring 13 is positioned on the right crankcase 12, and the other end is positioned on the positioning block 2 to form a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com