Nickel-containing powder metallurgy material for gear and preparation method thereof

A powder metallurgy and gear technology, applied in the field of powder metallurgy materials for nickel-containing gears and their preparation, can solve the problems of inferior dimensional accuracy, non-dense characteristics of parts, and performance of powder metallurgy parts that are inferior to forging, so as to improve the refining effect, The effect of increased surface hardness, yield strength and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

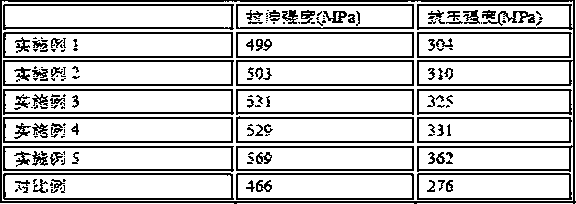

Examples

Embodiment 1

[0020] Step (1): Get the following raw materials respectively by weight percentage: zinc borate 0.08%, graphite powder 0.6%, boron-copper alloy powder 1.8%, nickel oxide 0.1%, iron powder surplus, the weight percentage sum of each composition is 100 %; the above-mentioned raw materials are mixed at high speed, and mixed until the above-mentioned materials are uniform; the raw materials are ball-milled with a ball mill, the ball-to-material ratio is 55:1, and the ball-milling time is 4.5h; step (2): the powder metallurgical material after ball milling Press molding, put the powder metallurgy material into the mold, pressurize the mold until the pressure is 625MPa, and press until the density of the above material is 7.8g / m3; step (3): put the powder metallurgy material after pressing High-temperature sintering, the high-temperature sintering temperature is divided into two stages, the first stage temperature is 845°C, sintering for 3 hours, and the temperature of the second stag...

Embodiment 2

[0022] Step (1): Get the following raw materials respectively by weight percentage: zinc borate 2%, graphite powder 0.3%, boron-copper alloy powder 3.2%, nickel oxide 0.3%, iron powder surplus, the weight percentage sum of each composition is 100 %; the above-mentioned raw materials are mixed at high speed, and mixed until the above-mentioned materials are uniform; the raw materials are ball-milled with a ball mill, the ball-to-material ratio is 35:1, and the ball-milling time is 3.5h; step (2): the powder metallurgy material after ball milling Press molding, put the powder metallurgy material into the mold, pressurize the mold until the pressure is 535MPa, and press until the density of the above material is 5.5g / m3; step (3): put the powder metallurgy material after pressing High-temperature sintering, the high-temperature sintering temperature is divided into two stages, the first stage temperature is 780°C, sintering for 3 hours, and the temperature of the second stage is r...

Embodiment 3

[0024] Step (1): Get the following raw materials respectively by weight percentage: zinc borate 0.38%, graphite powder 0.5%, boron-copper alloy powder 2.2%, nickel oxide 1%, iron powder surplus, the weight percentage sum of each composition is 100 %; the above-mentioned raw materials are mixed at high speed, and mixed until the above-mentioned materials are uniform; the raw materials are ball-milled with a ball mill, the ball-to-material ratio is 55:1, and the ball-milling time is 4.5h; step (2): the powder metallurgical material after ball milling Press molding, put the powder metallurgy material into the mold, pressurize the mold until the pressure is 625MPa, and press until the density of the above material is 7.8g / m3; step (3): put the powder metallurgy material after pressing High-temperature sintering, the high-temperature sintering temperature is divided into two stages, the first stage temperature is 845°C, sintering for 3 hours, and the temperature of the second stage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com