A clean graded quenching method for 0cr16ni5mo1 martensitic stainless steel

A technology of 0cr16ni5mo1 and martensitic stainless steel, applied in the field of heat treatment of steel materials, can solve the problems of difficult control of quenching medium conversion time, inapplicable quenching methods, and impracticability, and achieve good application prospects, eliminate adverse effects, and small residual stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

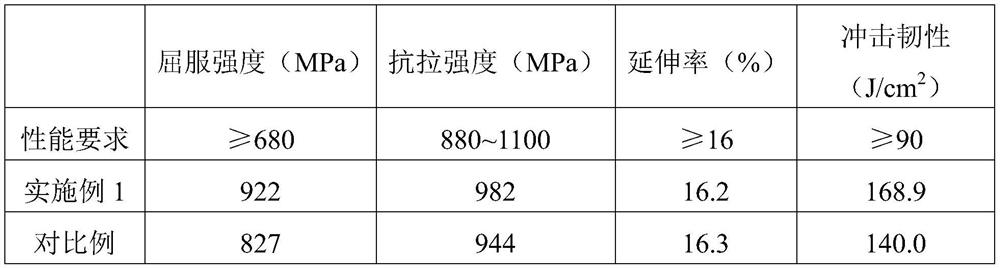

Embodiment 1

[0023] Heat treatment is carried out by using a block-shaped 0Cr16Ni5Mo1 martensitic stainless steel sample, which specifically includes the following steps:

[0024] Step 1: Raise the temperature of the empty quenching furnace to 1100°C. After the temperature is stable, put the sample into the furnace and keep it warm for 60 minutes;

[0025] Step 2: Take out the sample after heat preservation, put it into a hot water tank filled with 90°C hot water for quenching, and the stirring rate of the hot water tank is 5r / min;

[0026] Step 3: After the temperature of the workpiece is basically uniform, take it out of the hot water tank, put it into a cold water tank filled with a mixture of ice and water at 0-5°C to cool and keep it warm for 180 minutes.

[0027] Step 4: Take out the sample after cold treatment, put it back to room temperature and put it into a furnace heated to 580°C for tempering. The tempering time is 60 minutes, then take out the sample and cool it naturally in t...

Embodiment 2

[0037] A clean graded quenching method for 0Cr16Ni5Mo1 martensitic stainless steel, the method is as follows: the austenitized 0Cr16Ni5Mo1 martensitic stainless steel is first quenched into hot water for cooling, and after the internal temperature of the 0Cr16Ni5Mo1 martensitic stainless steel is uniform, then Cool in an ice-water mixture.

[0038] Wherein, the temperature of the hot water is 80°C, and the temperature of the ice-water mixture is 0°C. The time of cold treatment is 240min. After cold treatment, the 0Cr16Ni5Mo1 martensitic stainless steel was taken out and returned to room temperature in air.

[0039] Hot water is served in the hot water tank and the ice water mixture is served in the cold water tank. The hot water is selected from pure water with a boiling point of 100°C under standard atmospheric pressure, and the ice-water mixture is prepared by placing high polymer ice packs in water. The hot water tank is equipped with frequency conversion agitator, therm...

Embodiment 3

[0044] A clean graded quenching method for 0Cr16Ni5Mo1 martensitic stainless steel, the method is as follows: the austenitized 0Cr16Ni5Mo1 martensitic stainless steel is first quenched into hot water for cooling, and after the internal temperature of the 0Cr16Ni5Mo1 martensitic stainless steel is uniform, then Cool in an ice-water mixture.

[0045]Wherein, the temperature of the hot water is 100°C, and the temperature of the ice-water mixture is 5°C. The time of cold treatment is 120min. After cold treatment, the 0Cr16Ni5Mo1 martensitic stainless steel was taken out and returned to room temperature in air.

[0046] Hot water is served in the hot water tank and the ice water mixture is served in the cold water tank. The hot water is selected from pure water with a boiling point of 100°C under standard atmospheric pressure, and the ice-water mixture is prepared by placing high polymer ice packs in water. The hot water tank is equipped with frequency conversion agitator, therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com