Fully automatic control glue pouring system and method for continuous production of gradient gel films

A gradient gel, control system technology, applied in the field of biochemical detection, to achieve the effect of life and health protection and avoid frequent contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further illustrated below in conjunction with specific examples, but these examples are only for illustrating the present invention, rather than limiting the scope of the present invention.

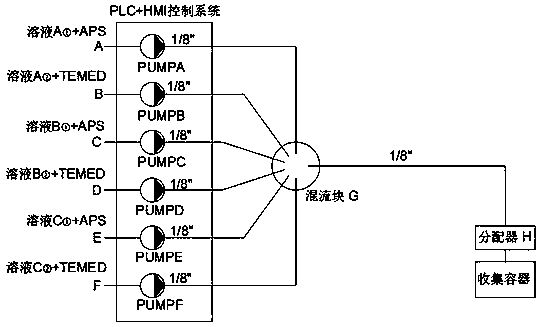

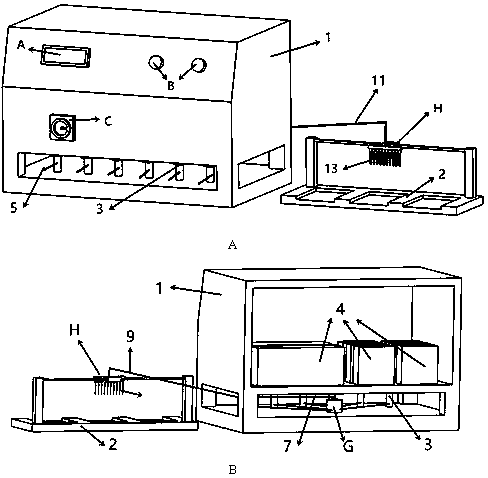

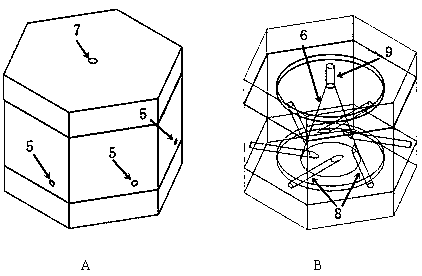

[0038] Such as figure 1 As shown, a kind of automatic control glue pouring system for the continuous production of gradient gel film of the present invention comprises: several precise constant flow pumps (i.e. figure 1 PUMPA, PUMPB, PUMPC, PUMPD, PUMPE, PUMPF), PLC+HMI control system for controlling the precision constant flow pump, mixed flow block, distributor and collection container; one end of the precision constant flow pump is the solution inlet, The solution outlet at the other end is connected to the mixed flow block; two different concentrations of solutions, respectively added with APS and TEMED, respectively enter the solution inlets of the two precision constant flow pumps; the mixed flow block is connected to the distributor, and the distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com