Cleaning control system and method thereof

A control system and switching valve technology, applied in the field of cleaning, can solve the problems of dead angle, poor descaling effect, and low degree of automation, so as to improve cleaning efficiency, reduce cleaning time, and improve the effect of automatic control operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

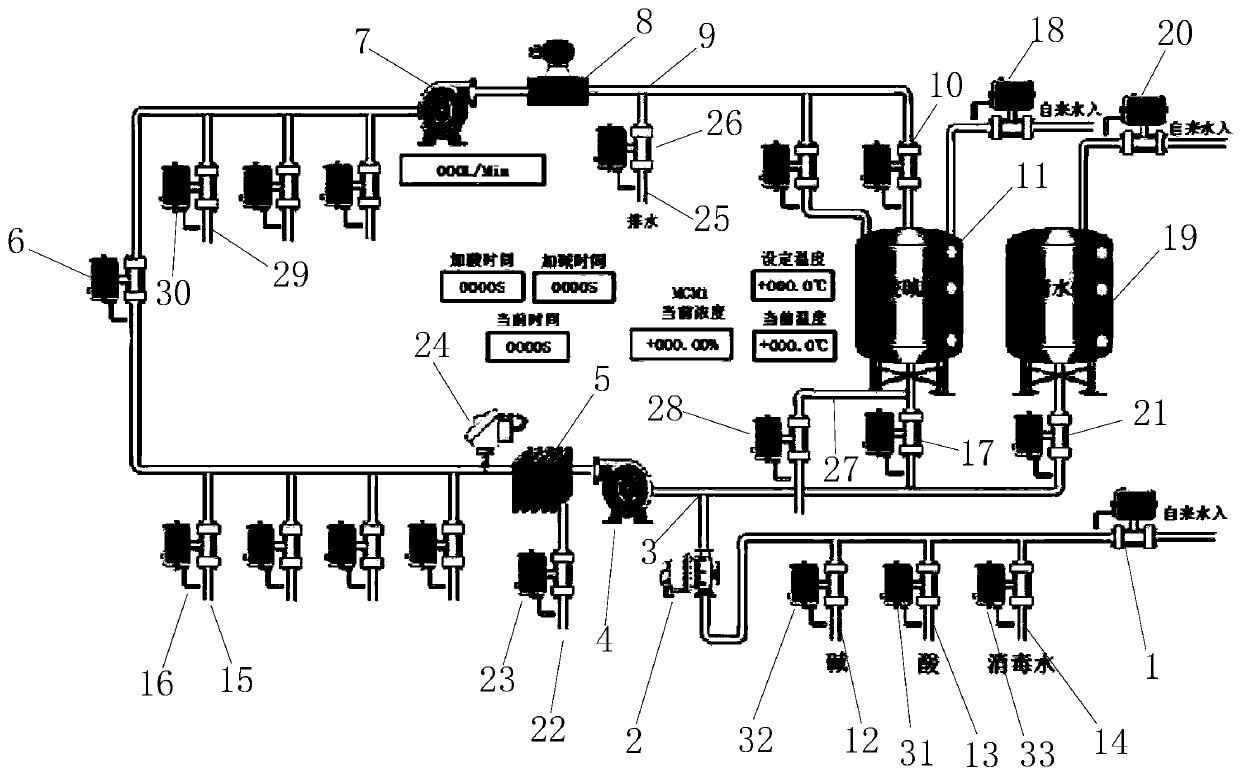

[0026] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

[0027] A cleaning control system, comprising a first tap water valve 1, a check valve 2, a first three-way pipe 3, a water supply pump 4, a plate heat exchanger 5, and a first on-off valve 6 arranged sequentially through water pipes according to the flow direction of the liquid , reflux pump 7, flow meter 8, second tee pipe 9, second switching valve 10 and acid-base cylinder 11.

[0028] The water pipe between the first running water valve 1 and the check valve 2 is connected with an alkali water pipe 12, an acid water pipe 13 and a disinfection water pipe 14, and the alkali water pipe 12 is provided with an alkali water valve 32, and the acid water pipe 13 is provided with an acid water valve 31, The disinfection water pipe 14 is provided with a disinfection water valve 33 .

[0029] The water pipe between the plate heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com