Vertical pneumatic bending, flavoring and feeding device

A pneumatic mixing and feeding device technology, which is applied in the fields of application, tobacco, and tobacco preparation, can solve the problems of inability to quickly respond to production switching, poor application accuracy stability, and inability to improve inherent defects, so as to avoid frequent contact, improve cigarette quality, and low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

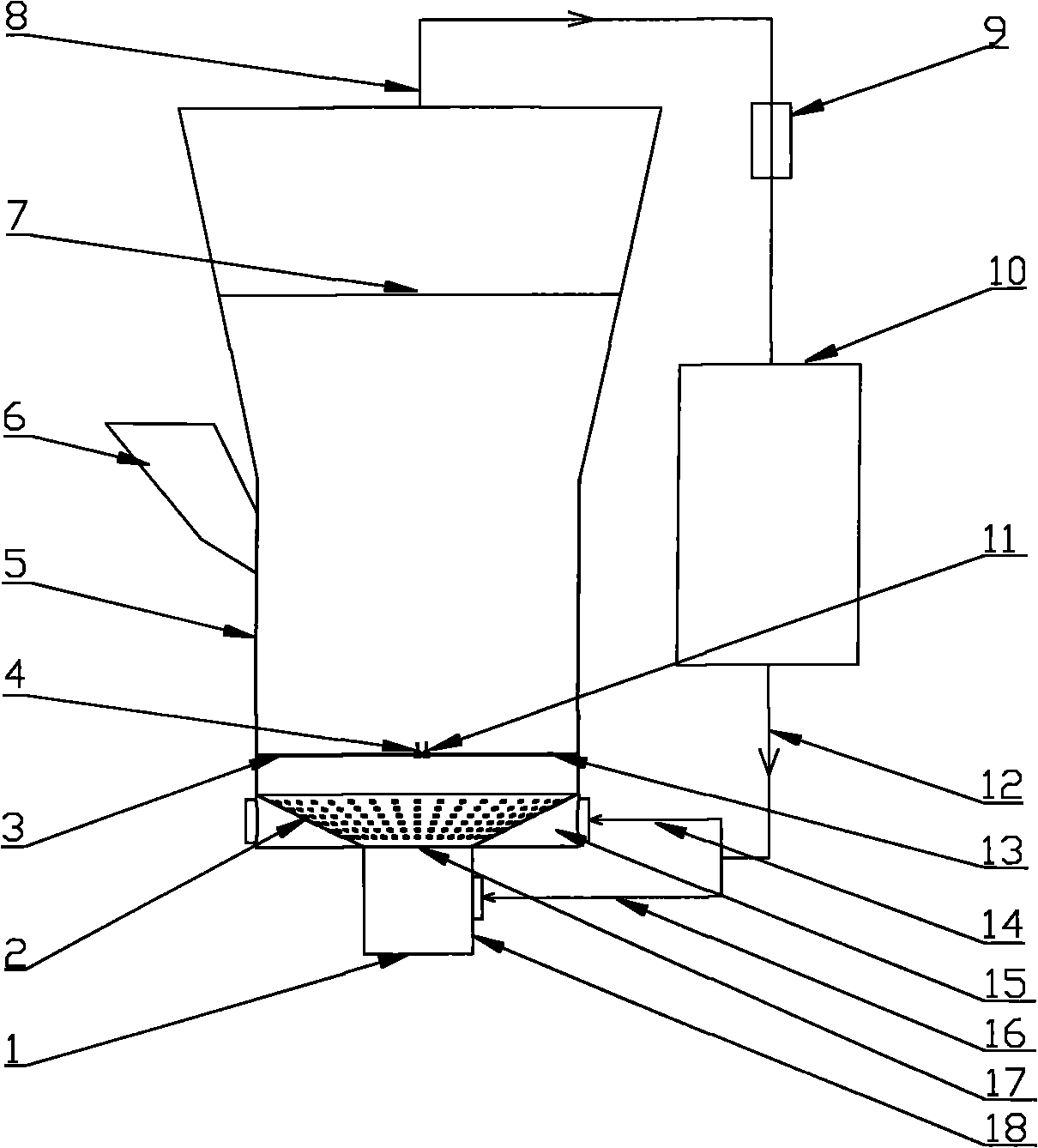

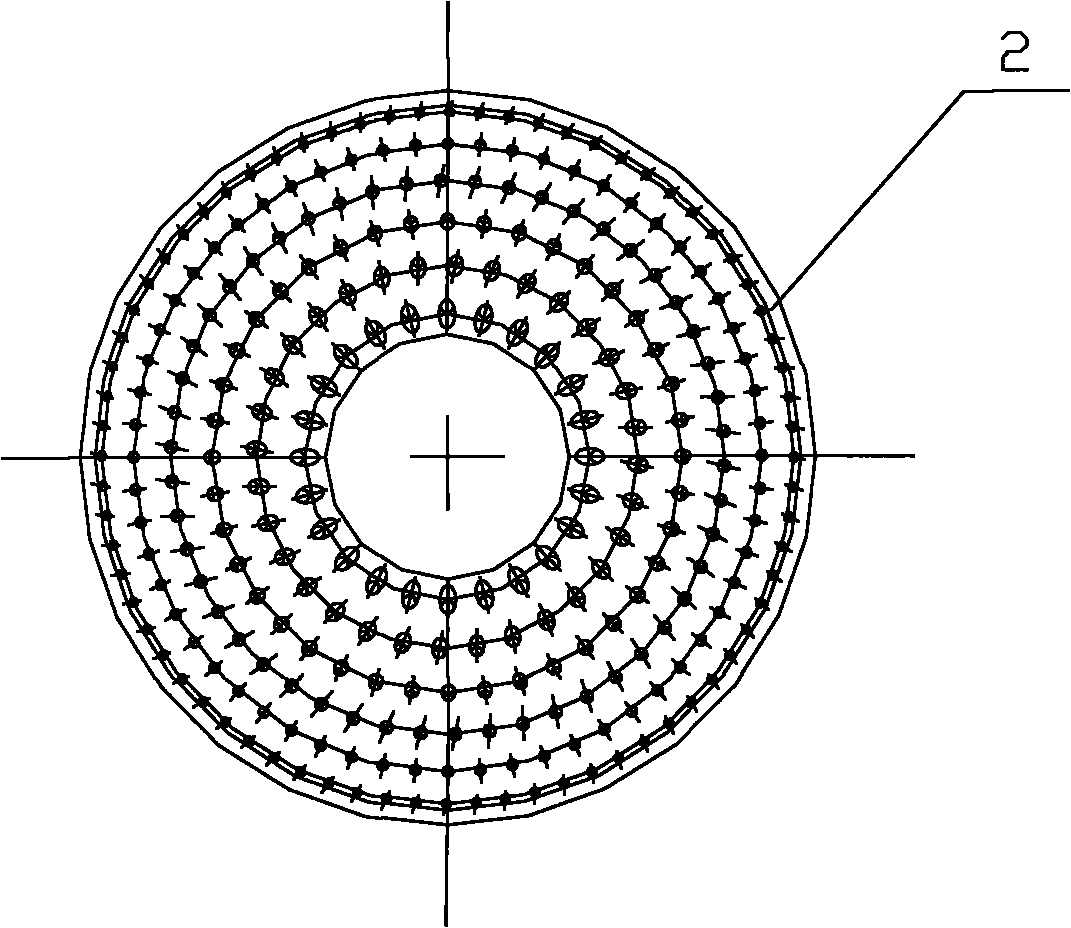

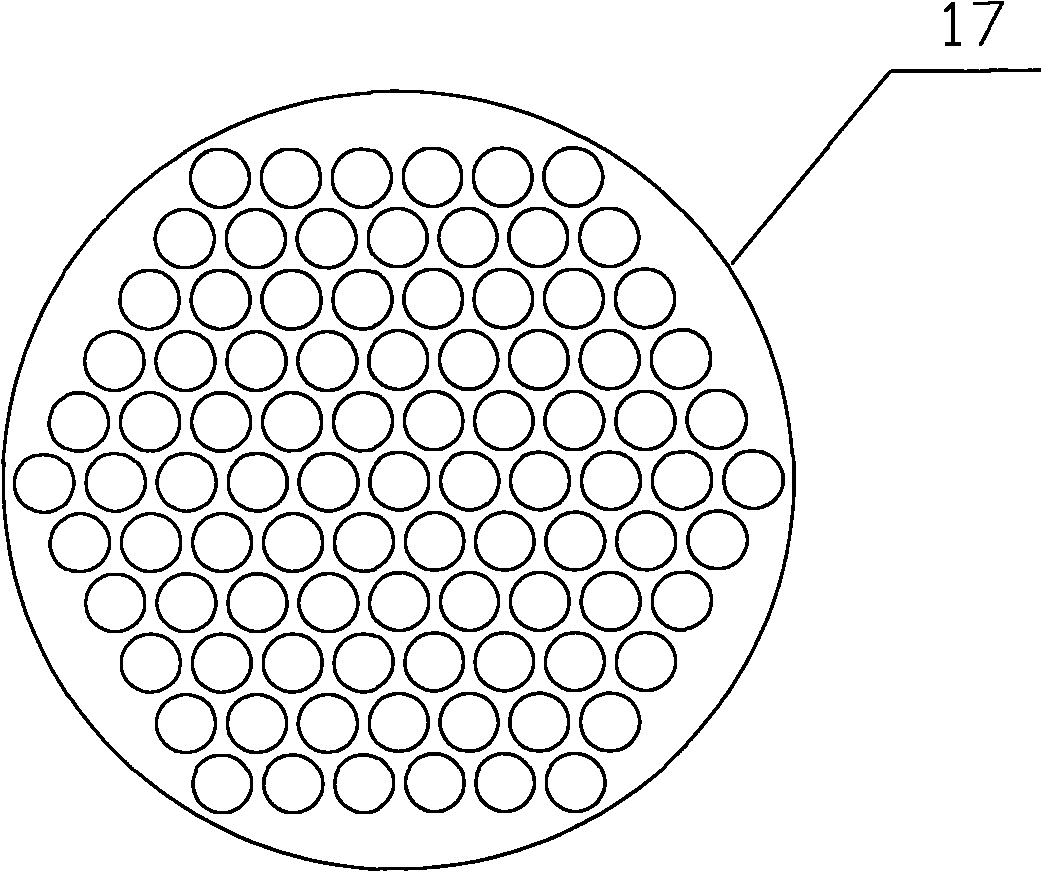

[0015] combine figure 1 , the vertical pneumatic mixing, flavoring and feeding device of the present invention includes a tobacco leaf feed hopper 6, a main working cylinder 5, a flavoring and feeding nozzle 4 and its bracket and pipeline 3, a temperature increasing and humidifying nozzle 11 and its bracket and pipeline 13, Tobacco leaf filter 7, material liquid filter element 9, hot air circulation system 10 and its hot air duct 12, air distribution system, discharge gate 1, the air distribution system consists of conical air distribution plate 2, peripheral air supply duct 14, peripheral air flow The cavity 15, the central air supply duct 16, the central air duct 18 and the central orifice 17 are composed of the feed hopper 6 located on the side wall of the main working cylinder 5, and the tobacco leaves are installed sequentially in the main working cylinder 5 from top to bottom. Filter screen 7, flavoring and feeding nozzle 4 and its bracket and pipeline 3, temperature inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com