Capsule filter rod capable of reducing releasing amount of harmful substances in flue gas

A technology of harmful substances and release amount, applied in e-liquid filter, tobacco, food science and other directions, can solve the influence of cigarette smoking style and cost factors without considering the difficulty of production process, increase the difficulty of using materials, instability, etc. problems, to achieve the effect of improving the suction experience, low cost, and ensuring the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

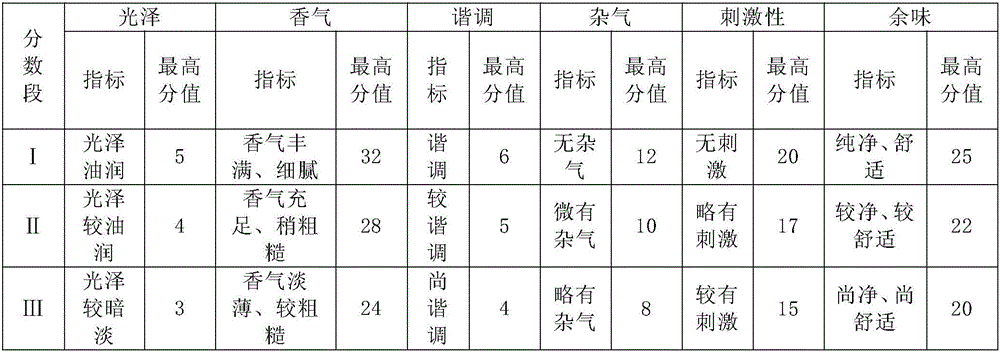

[0021] Brittle capsule core material proportioning of the present invention is as follows:

[0022] ingredients

[0023] The preparation steps of the present invention are as follows: mix 5.0% glyceryl triacetate, 2.0% damascenone and 93.0% caprylic capric glyceride in mass percentage, wrap it in capsules after stirring evenly, and place the capsules in the cigarette Capsules are added to the filter rod during the forming process of the filter rod to obtain a capsule filter rod that can reduce the release of harmful substances in the smoke, and then a sample cigarette containing the capsule filter rod is made. Before cigarette smoking, the capsule in the filter rod is crushed to release the capsule core material, and the test sample and the control sample are smoked on the smoking machine according to the standard smoking conditions, and the mainstream smoke test is carried out according to the relevant standards. The analysis results are shown in Table 1 and Table 2...

Embodiment 2

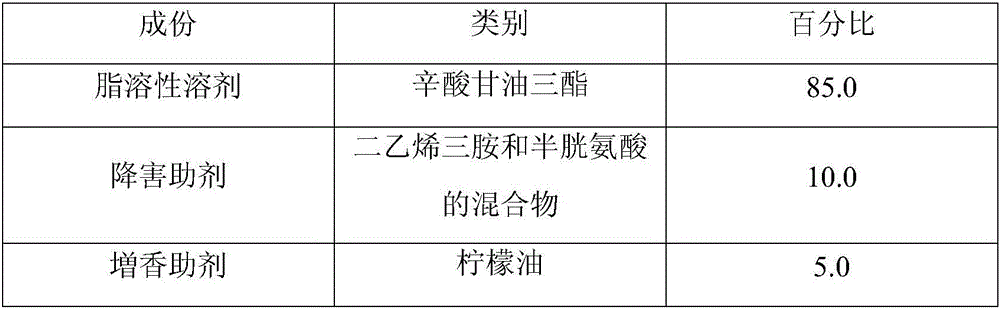

[0025] Brittle capsule core material proportioning of the present invention is as follows:

[0026]

[0027] The preparation steps of the present invention are: a mixture of 10.0% diethylenetriamine and cysteine by mass percentage (the mass ratio of diethylenetriamine to cysteine is 1:1), 5.0% lemon oil and 85.0% caprylic triglycerides are mixed, stirred evenly and wrapped in capsules, and the capsules are added to the filter rods during the cigarette filter rod forming process to obtain a capsule filter rod that can reduce the release of harmful substances in the smoke. Sample cigarettes containing capsule filter rods were then made. Before cigarette smoking, the capsule in the filter rod is crushed to release the capsule core material, and the test sample and the control sample are smoked on the smoking machine according to the standard smoking conditions, and the mainstream smoke test is carried out according to the relevant standards. The analysis results are shown...

Embodiment 3

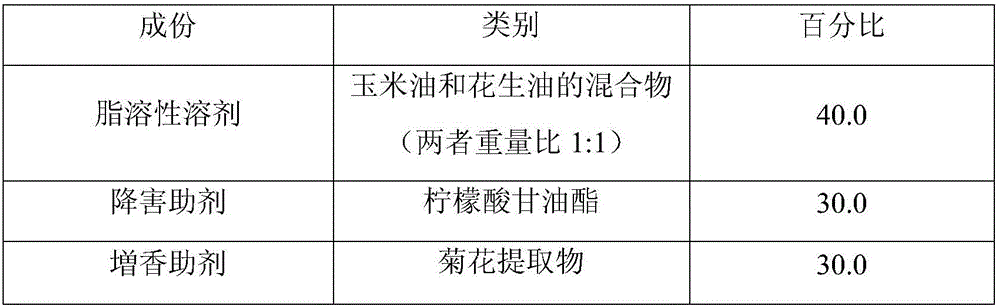

[0029] Brittle capsule core material proportioning of the present invention is as follows:

[0030]

[0031] The preparation steps of the present invention are: mixing 12.0% glycerin citrate, 10.0% chrysanthemum extract (vegetable essential oil) and 78.0% corn oil in mass percentage, wrapping it in a capsule after stirring evenly, and putting it in a cigarette Capsules are added to the filter rod during the forming process of the filter rod to obtain a capsule filter rod that can reduce the release of harmful substances in the smoke, and then a sample cigarette containing the capsule filter rod is made. Before cigarette smoking, the capsule in the filter rod is crushed to release the capsule core material, and the test sample and the control sample are smoked on the smoking machine according to the standard smoking conditions, and the mainstream smoke test is carried out according to the relevant standards. The analysis results are shown in Table 1 and Table 2. At the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com