Belt transmission-type microstrainer

A belt drive and microfilter technology, applied in the direction of moving filter element filters, filtration separation, separation methods, etc., can solve the problems of inability to push the drum, motor damage, drum acceleration speed, etc., to avoid manual intervention and automatic cleaning. , the effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

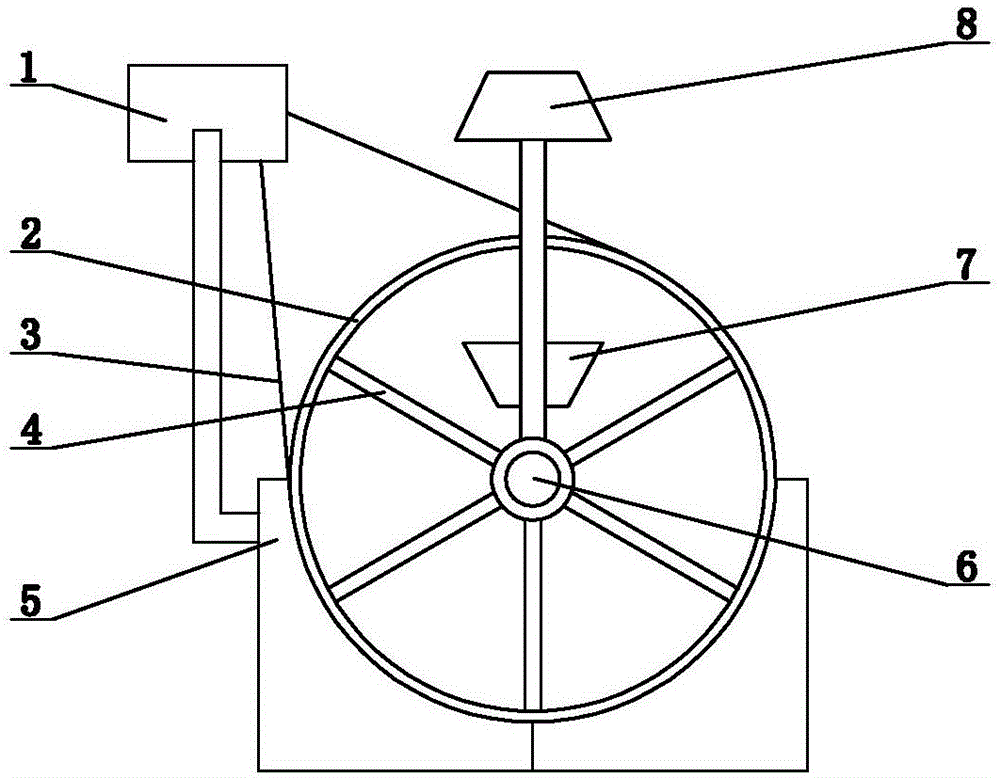

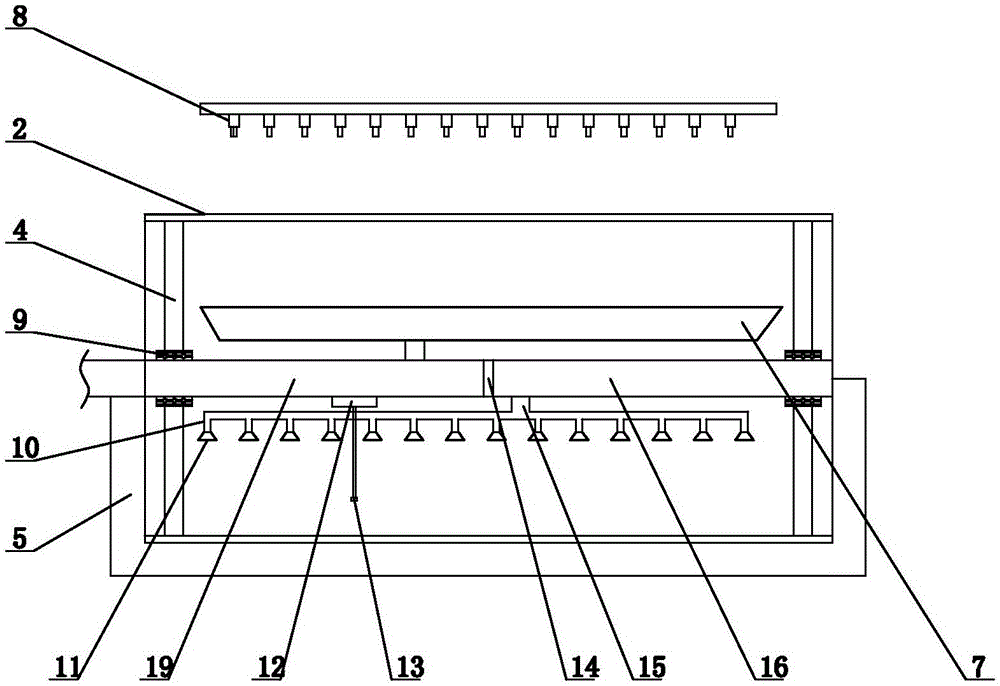

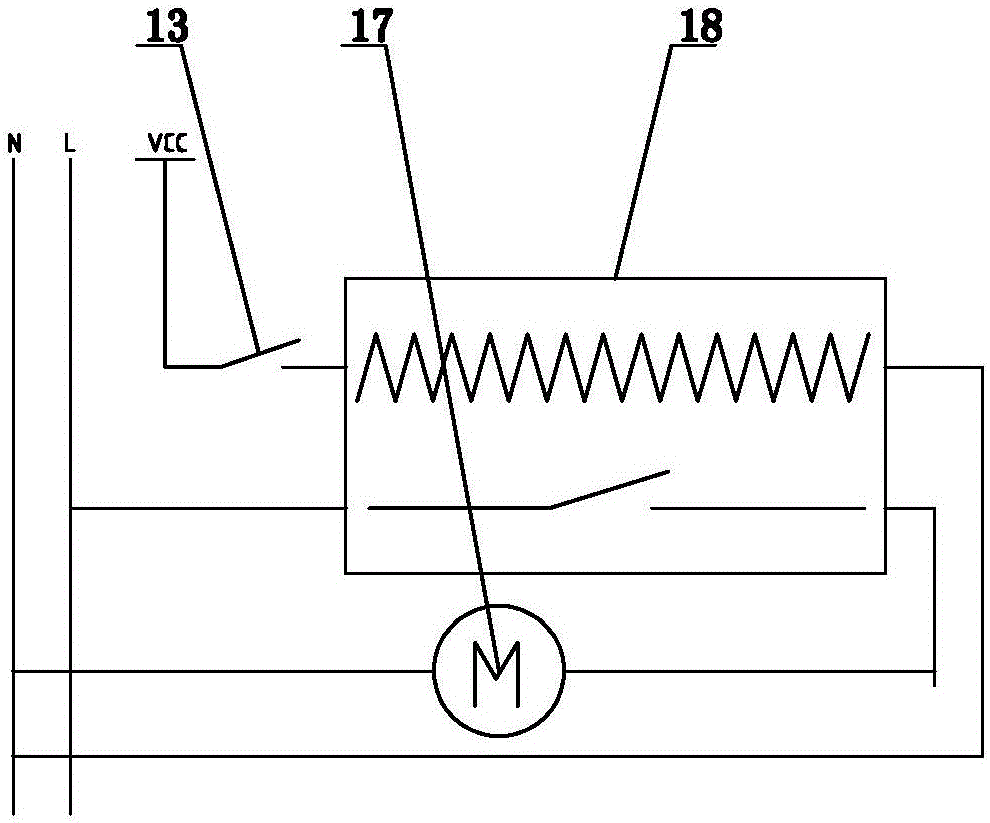

Embodiment 1

[0015] Embodiment 1: as figure 1 with figure 2 As shown, the belt-driven microfilter of the present invention includes a drum, and the drum includes a drum frame 4 and a filter screen 2 wrapped outside the drum frame 4. Both ends of the drum frame 4 are sleeved on the central shaft 6 through bearings 9, and the middle The shaft 6 is hollow, and the hollow part is divided into two parts by the baffle plate 14, which are respectively A part 16 and B part 19. The dirt collection tank 7 on the central shaft 6 is also provided with a high-pressure water gun 8 on the central shaft 6. The high-pressure water gun 8 is located outside the drum frame 4, and the dirt collection tank 7 is located in the drum frame 4. The dirt collection tank 7 is in the same position as the high-pressure water gun 8. Cooperate, the water sprayed by the high-pressure water gun 8 will fall into the dirt collection tank 7 after washing the filter screen 2, the central shaft 6 is installed on the support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com