Cyclone slug capturer

A trap, plug flow technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of heavy TP plate separation load, hydraulic impact, blocked liquid level, etc., to reduce the total investment of the project, Save operating costs and alleviate the effect of slug flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further disclose the technical solution of the present invention, below in conjunction with accompanying drawing of description, elaborate in detail through embodiment:

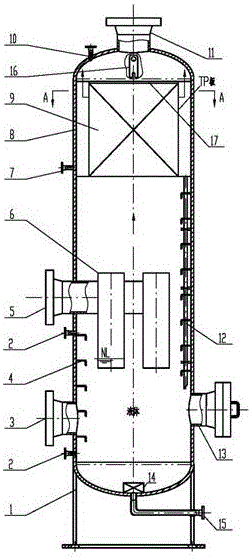

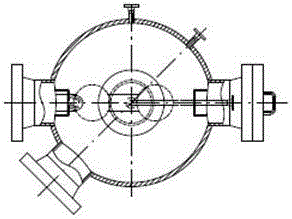

[0021] refer to figure 1 , 2 , 3, 4, the present invention relates to an oil-gas mixed transport slug catcher device for catching slug flow, which mainly consists of a housing 8, a TP plate assembly 9, a swirl cylinder 6, a vortex breaker 14, Downcomer 12, gas outlet 11, liquid outlet 3, sewage outlet 15, safety valve 7, liquid level gauge / transmitter 2, pressure gauge 10, and manhole 13.

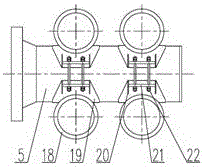

[0022] A swirl slug catcher, comprising a housing, a gas inlet is provided in the tangential direction in the middle of the housing, a swirl cylinder 6 is installed in the housing 8 at the gas inlet 5, and the upper gas space in the housing 8 A TP plate assembly 9 with radial channels is installed inside. The slug flows through the gas inlet 5 and enters each swirl tube 18 of the swirl cylinder 6 alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com