High-efficiency sample oscillation and uniform mixing device and use method

A sample and mixing technology, applied in the direction of shaking/oscillating/vibrating mixers, chemical instruments and methods, mixers, etc., can solve the problems of long time consumption, low degree of automation, sample loss, etc., and achieve avoidance of collision wear and connection Good performance and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

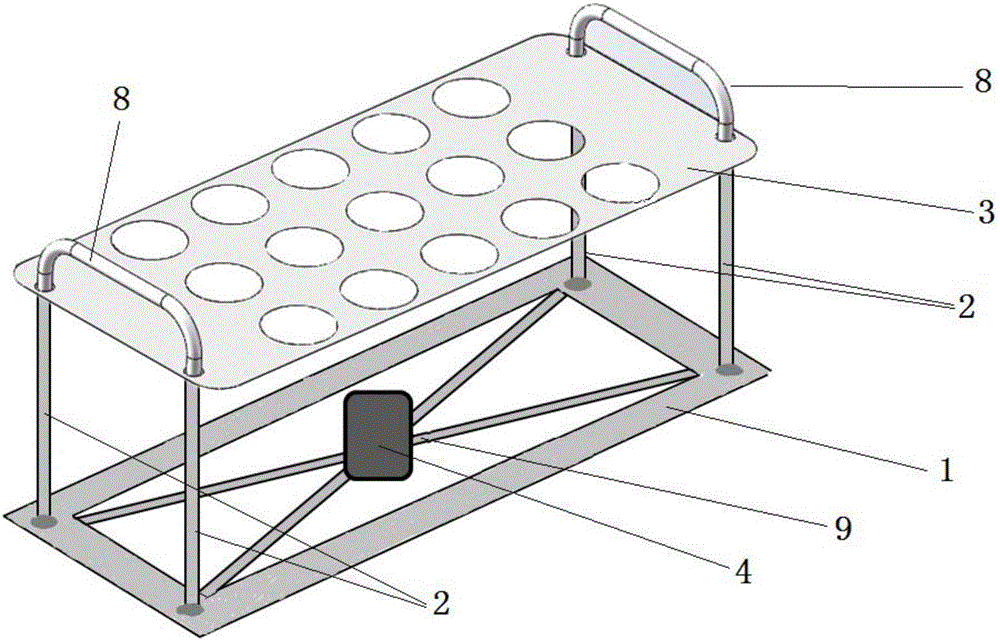

[0015] like figure 1 As shown, the present invention provides a high-efficiency sample oscillating and mixing device, which includes a base 1 , four supports 2 , a sample holder 3 and an eccentric motor vibration system 4 . The upper part of the base 1 is connected to the sample holder 3 through four brackets 2, and an eccentric motor vibration system 4 is installed in the middle of the base 1. The eccentric motor vibration system 4 is vertically arranged, and the vibration effect of the eccentric motor vibration system 4 itself is emitted. In the sample rack 3, the samples can be better mixed evenly.

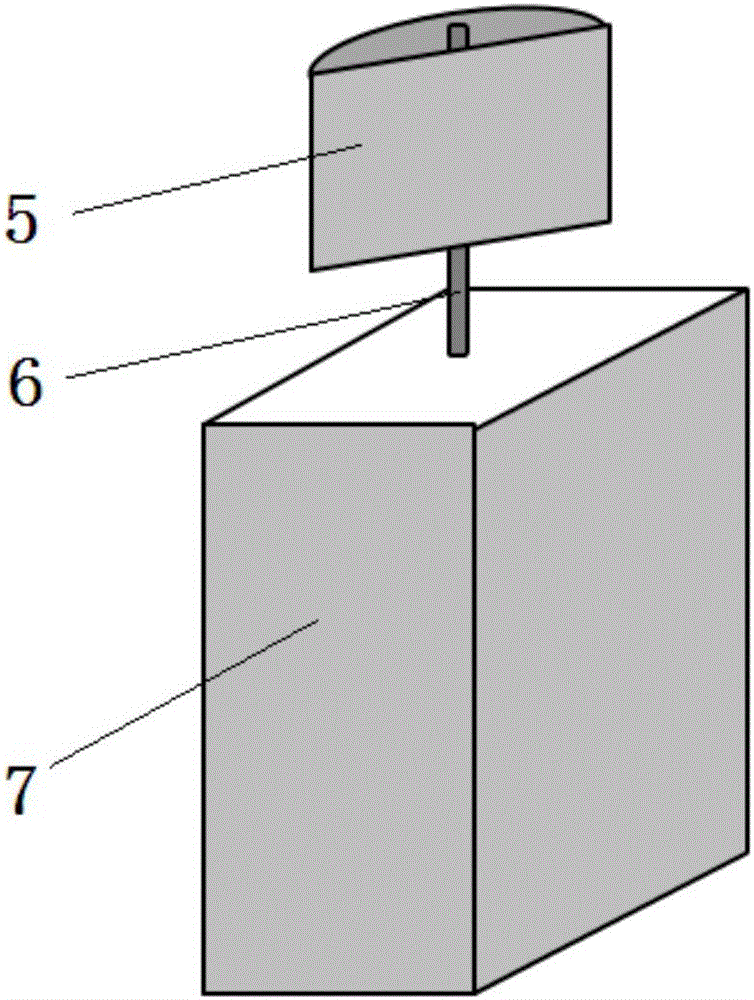

[0016] In the above example, if figure 2 As shown, the eccentric motor vibration system 4 is composed of a semi-cylindrical block 5 that deflects the center of gravity, a bearing 6, a motor 7 and a control system. The semi-cylindrical block 5 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com