Polyoxometalate-based loading-type catalyst for oil product desulfurization and preparing method thereof

A supported catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as easy decomposition, easy loss of acid, loss of catalytic activity, etc., and achieve high catalytic efficiency , good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

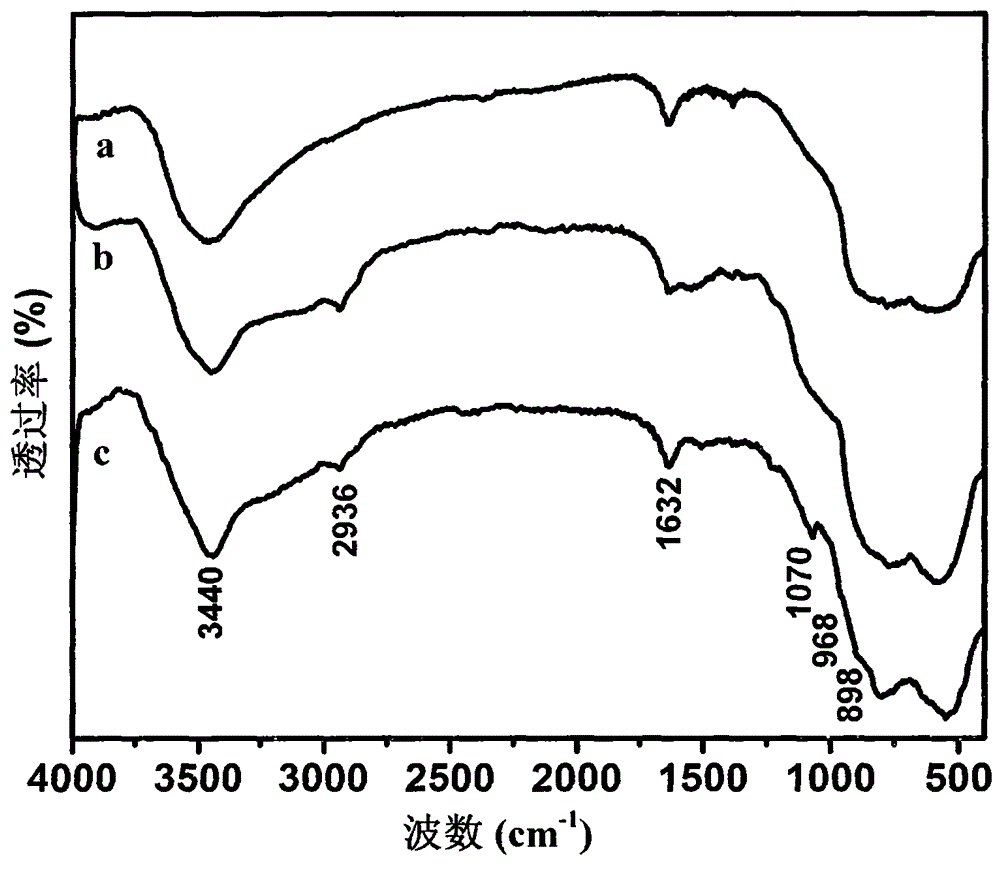

[0015] (1) Put about 0.8g of pretreated γ-Al in a 50mL three-neck round bottom flask 2 o 3 and 25mL dry toluene, add 0.75mL 3-aminopropyltriethoxysilane under nitrogen atmosphere, heat and stir to reflux for 24h;

[0016] (2) Take out the treated γ-Al in step (1) 2 o 3 Pellet, in N 2 Wash with freshly prepared absolute ethanol for 10 h under atmosphere to remove γ-Al 2 o 3 Dry the pellets in a constant temperature drying oven at 80°C for 12 hours to obtain amino-modified γ-Al 2 o 3 , denoted as NH 2 -Al 2 o 3 ;

[0017] (3) NH prepared in step (2) 2 -Al 2 o 3 Add it into the dilute hydrochloric acid solution with pH=4.0, soak for 4 hours, take out the pellet and dry it under vacuum at room temperature.

[0018] (4) Weigh 0.2g of phosphotungstic acid to prepare an aqueous solution of phosphotungstic acid, and add the NH 2 -Al 2 o 3 After soaking the pellets for 4 hours, take them out and wash them three times with deionized water, 10 mL each time, and dry them ...

Embodiment 2

[0020] (1) Put about 0.8g of pretreated γ-Al in a 50mL three-neck round bottom flask 2 o 3 and 25mL dry toluene, add 0.75mL 3-aminopropyltrimethoxysilane under nitrogen atmosphere, heat and stir to reflux for 24h;

[0021] (2) Take out the treated γ-Al in step (1) 2 o 3 Pellet, in N 2 Wash with freshly prepared absolute ethanol for 10 h under atmosphere to remove γ-Al 2 o 3 Dry the pellets in a constant temperature drying oven at 80°C for 12 hours to obtain amino-modified γ-Al 2 o 3 , namely NH 2 -Al 2 o 3 ;

[0022] (3) NH prepared in step (2) 2 -Al 2 o 3 Add it into the dilute hydrochloric acid solution with pH=4.0, soak for 4 hours, take out the pellet and dry it under vacuum at room temperature.

[0023] (4) Weigh 0.2g of silicotungstic acid to prepare an aqueous solution of silicotungstic acid, and add the NH 2 -Al2 o 3 After soaking for 4 hours, the pellets were taken out and washed three times with deionized water, 10 mL each time, and vacuum-dried at ro...

Embodiment 3

[0025] (1) Put about 0.8g silicon-containing Al into a 50mL three-neck round bottom flask 2 o 3 (denoted as SiO 2 @Al 2 o 3 ) and 25mL dry toluene, add 0.75mL 3-aminopropyltriethoxysilane under nitrogen atmosphere, heat and stir to reflux for 24h;

[0026] (2) Take out the SiO treated in step (1) 2 @Al 2 o 3 , at N 2 Wash with freshly prepared absolute ethanol for 10 h under atmosphere to remove SiO 2 @Al 2 o 3 Dry in a constant temperature drying oven at 80°C for 12 hours to obtain amino-modified γ-Al 2 o 3 , namely NH 2 -SiO 2 @Al 2 o 3 ;

[0027] (3) NH prepared in step (2) 2 -SiO 2 @Al 2 o 3 Add it into the dilute hydrochloric acid solution with pH=4.0, soak for 4 hours, take out the pellet and dry it under vacuum at room temperature.

[0028] (4) Weigh 0.2g of phosphotungstic acid to prepare an aqueous solution of phosphotungstic acid, and add the NH 2 -SiO 2 @Al 2 o 3 After soaking the pellets for 4 hours, take out the pellets and wash them three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap