Multifunctional ejector

An ejector and multi-functional technology, which can be used in ejection devices, liquid ejection devices, etc., can solve the problems of unstable high-pressure steam, unavailability of pressure, and increase in production cost, so as to improve the accuracy of regulation, reduce waste, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

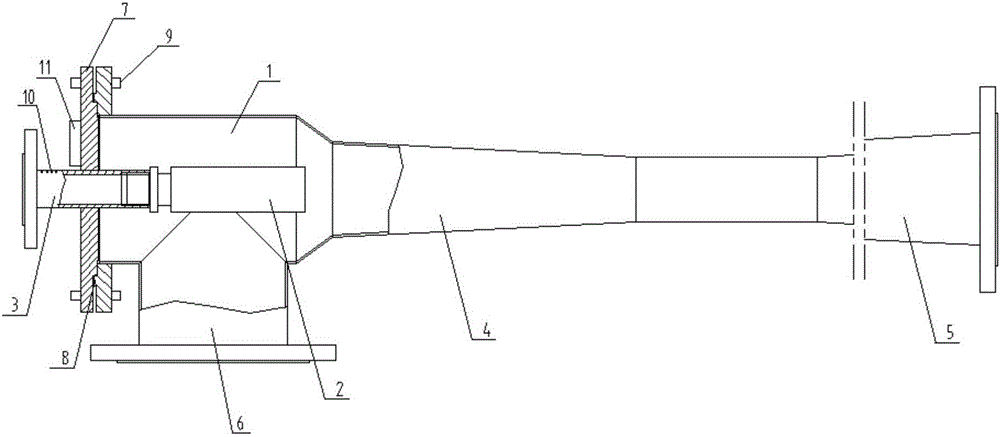

[0014] like figure 1 As shown, a multifunctional injector includes a main body pipe 1, a nozzle 2, a steam inlet pipe 3, a diffuser pipe 4 and an injection pipe 5. Air port 6, the front end of the main body pipe 1 is provided with a door body 7 sealing its front end, the door body 7 is detachably connected to the front end of the main body pipe 1, and the nozzle 2 is placed horizontally on the main body pipe 1, the steam inlet pipe 3 extends from the outside through the door body 7 into the main pipe 1 and is in sealing communication with the front end of the nozzle 2, and the steam inlet pipe 3 can drive the nozzle 2 back and forth Move horizontally, the diffuser tube 4 is fixedly placed at the rear end of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com