Single-centre die used for machining copper pipe

A technology of thimbles and copper tubes, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as easy breakage, and achieve the effects of not easy to deform and damage, stable structure, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

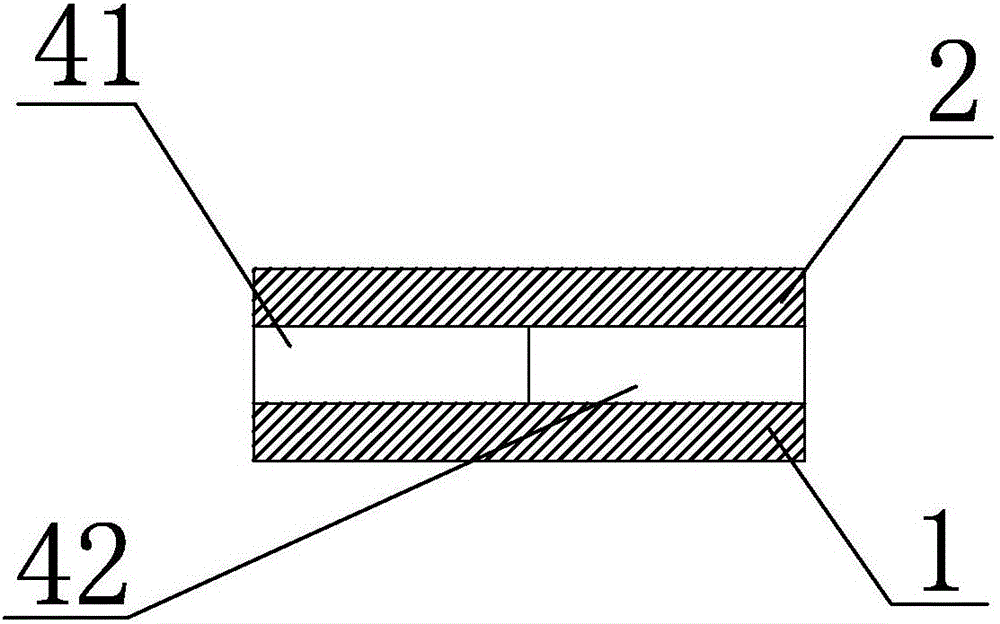

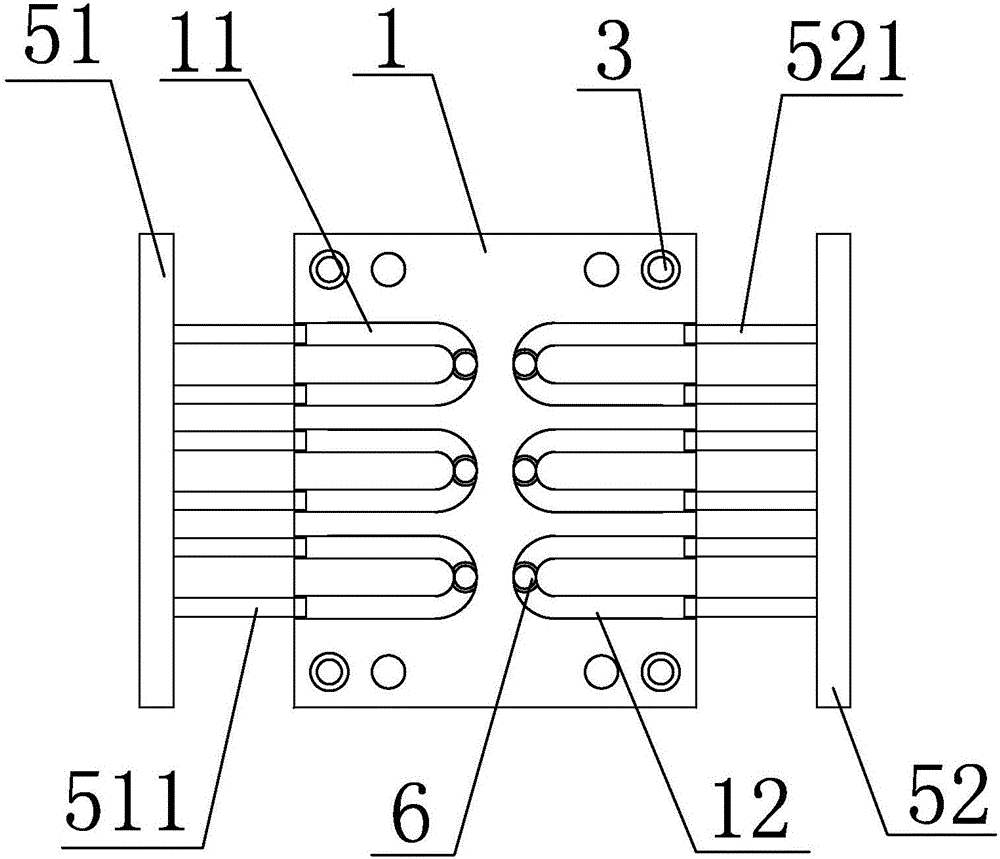

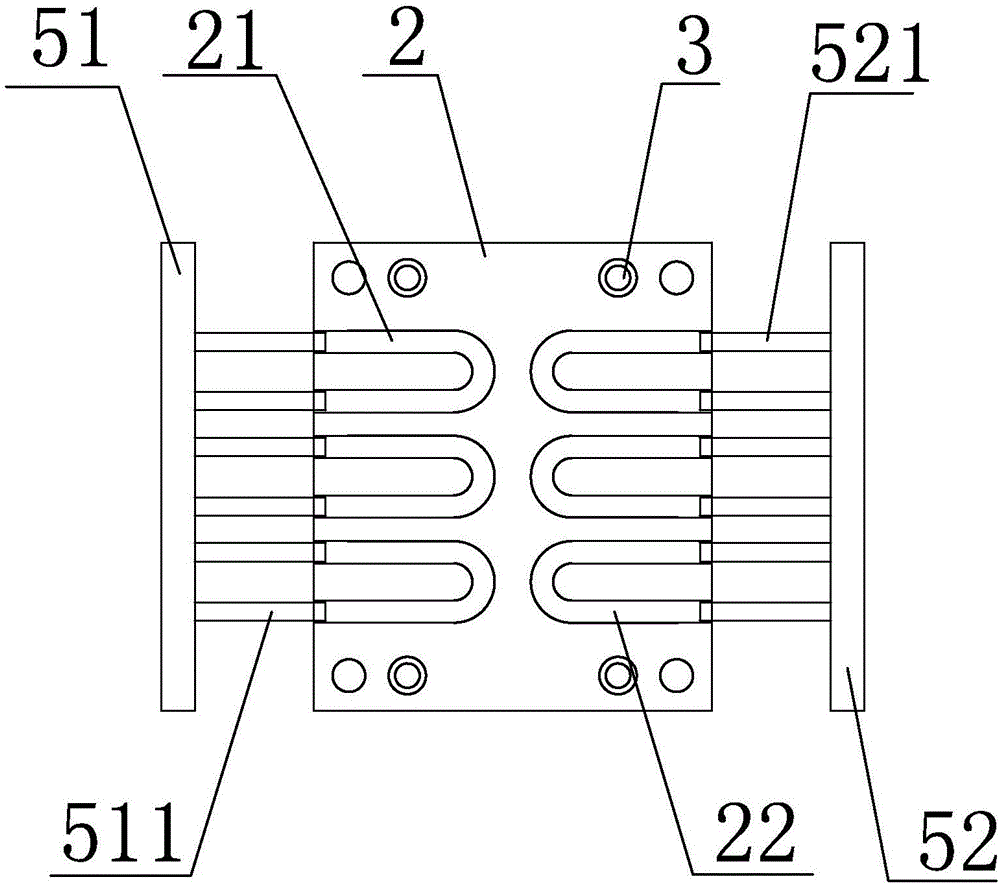

[0015] Such as Figure 1~3 As shown, the single thimble mold for processing copper pipes has a structure including a lower mold body 1 and an upper mold body 2, the lower mold body 1 and the upper mold body 2 are in the shape of a cuboid, and the lower mold body 1 and the upper mold body 2 are connected by bolts 3 connection, the lower mold body 1 is provided with a first U-shaped groove 11 and a second U-shaped groove 12, and the upper mold body 2 is provided with a third U-shaped groove 21 and a fourth U-shaped groove 22. The U-shaped groove 11 is symmetrical to the second U-shaped groove 12, the third U-shaped groove 21 is symmetrical to the fourth U-shaped groove 22, and the first U-shaped groove 11 is symmetrical to the third U-shaped groove 21. The position corresponds to form the first U-shaped pipe mold 41, the position of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com