Method of 3D motion simulation of high-altitude curtain wall installation robot

A technology of three-dimensional movement and robotics, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., and can solve problems such as teleoperation delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

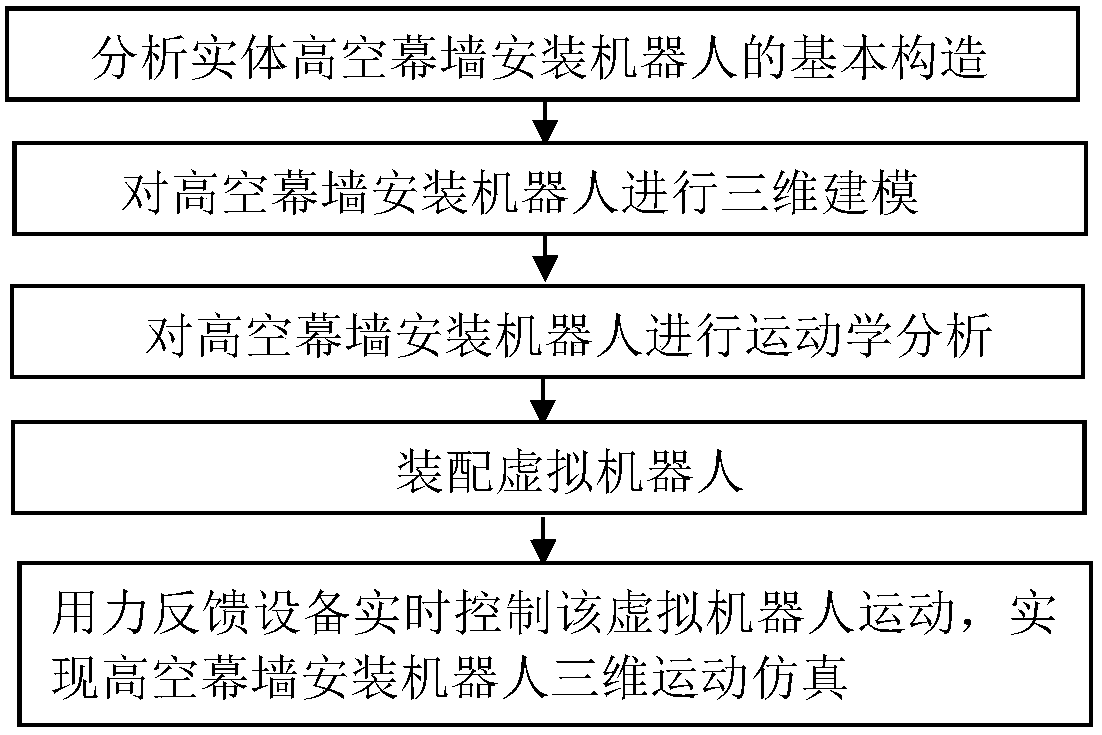

[0090] The three-dimensional motion simulation method of the high-altitude curtain wall installation robot of the present embodiment, the steps are as follows:

[0091] The first step is to analyze the basic structure of the solid high-altitude curtain wall installation robot:

[0092] Analyze the basic structure of the solid high-altitude curtain wall installation robot, and determine the structure and size of the main components of the high-altitude curtain wall installation robot;

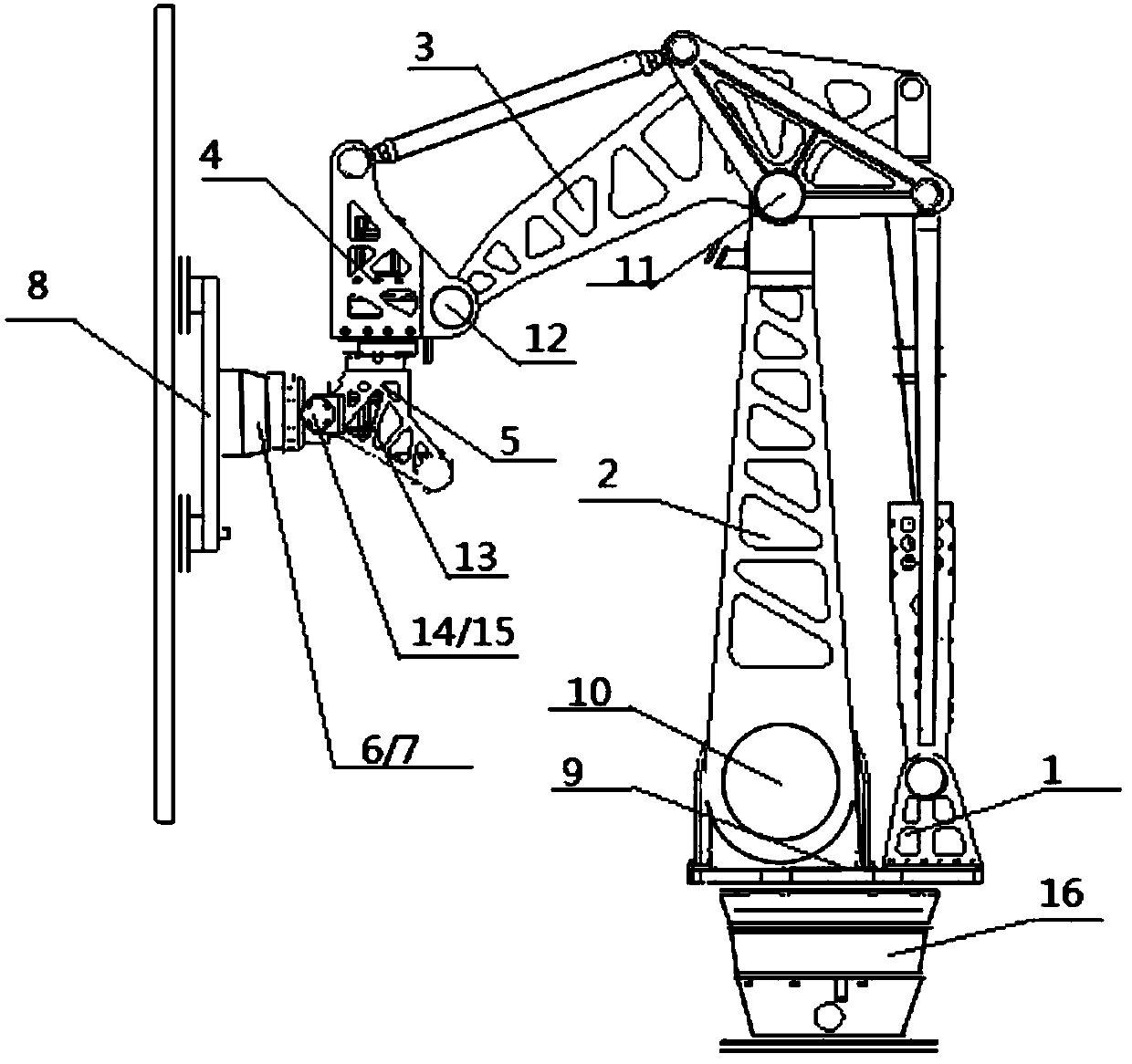

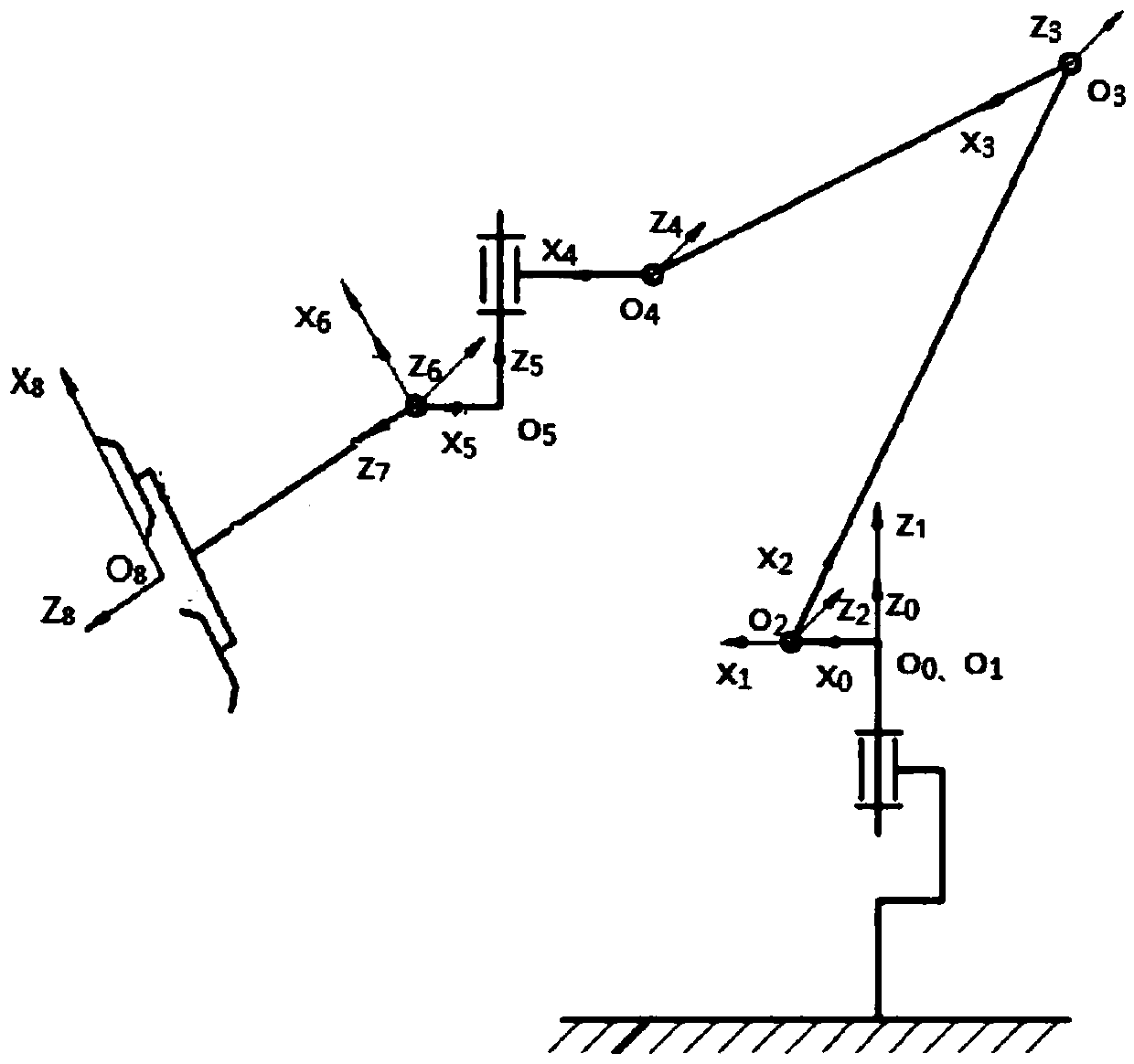

[0093] The basic structure of the entity of the high-altitude curtain wall installation robot of this embodiment is as described above figure 2 In the embodiment shown, the main components of the high-altitude curtain wall installation robot, that is, the structure and size of each connecting rod, that is, the connecting rod parameter table, are shown in Table 1.

[0094] Table 1 Parameters of the connecting rod of the high-altitude curtain wall installation robot

[0095]

[0096] The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com