A coil type permanent magnet electric levitation device for maglev train

An electric suspension and maglev train technology, applied in electric vehicles, vehicle components, electric traction, etc., can solve the problems of inapplicability to high-speed fields, low mechanical strength of thin-plate structures, unfavorable engineering, etc., and achieve good high-speed performance, simple structure, Weak skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

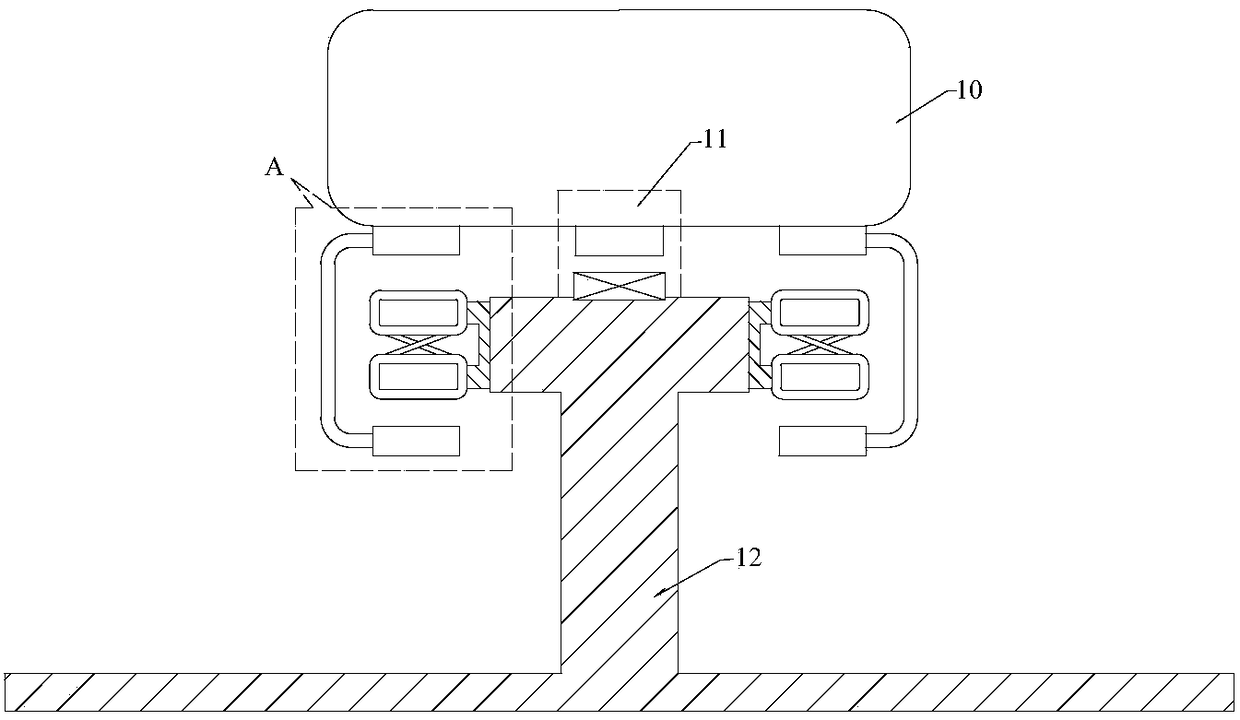

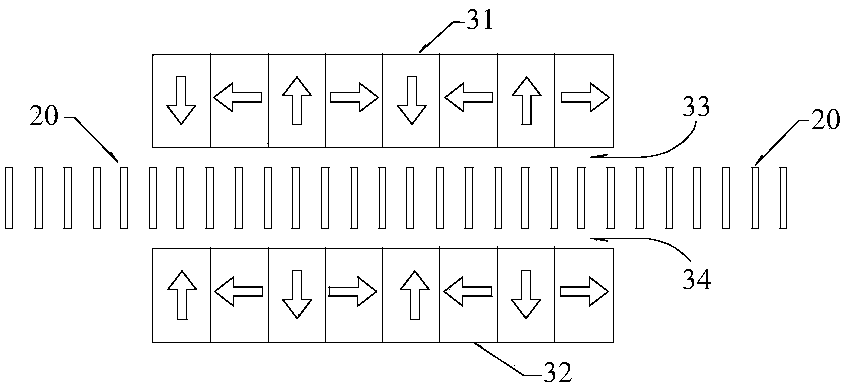

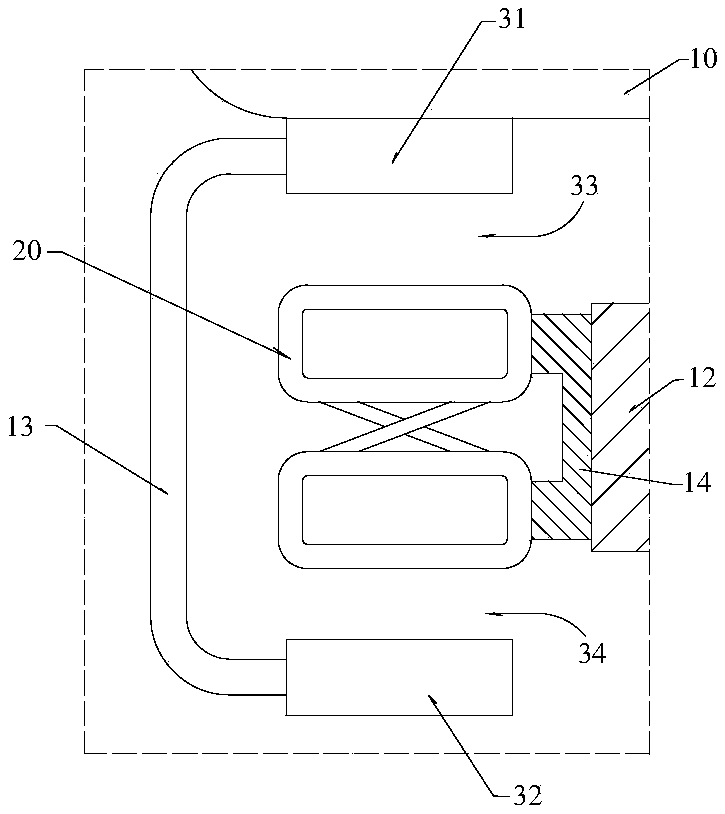

[0017] refer to figure 1 and figure 2 , a coil type permanent magnet electric levitation device for a maglev train of the present invention includes a train body 10, a track 12, and a linear motor 11 that drives the train body 10 to move along the track 12. A group of coils are fixedly installed on both sides of the track 12 , and each group of coils is composed of several zero-flux coils 20 arranged at intervals along the extending direction of the track 12 . The bilateral permanent magnet arrays corresponding to the coils are transversely spaced on the train body 10, and the bilateral permanent magnet arrays include an upper linear Halbach array 31 above the zero-flux coil 20 and a lower linear Halbach array below the zero-flux coil 20. In the Halbach array 32 , there is an upper air gap 33 between the zero flux coil 20 and the bottom surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com