A wire-controlled electronically controlled double-shift bicycle central axle gearbox

A technology for bicycles and gearboxes, which is applied to bicycle gear transmission mechanisms, vehicle gearboxes, and bicycle accessories. Speed adjustment is quick and convenient, and the effect of wide speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

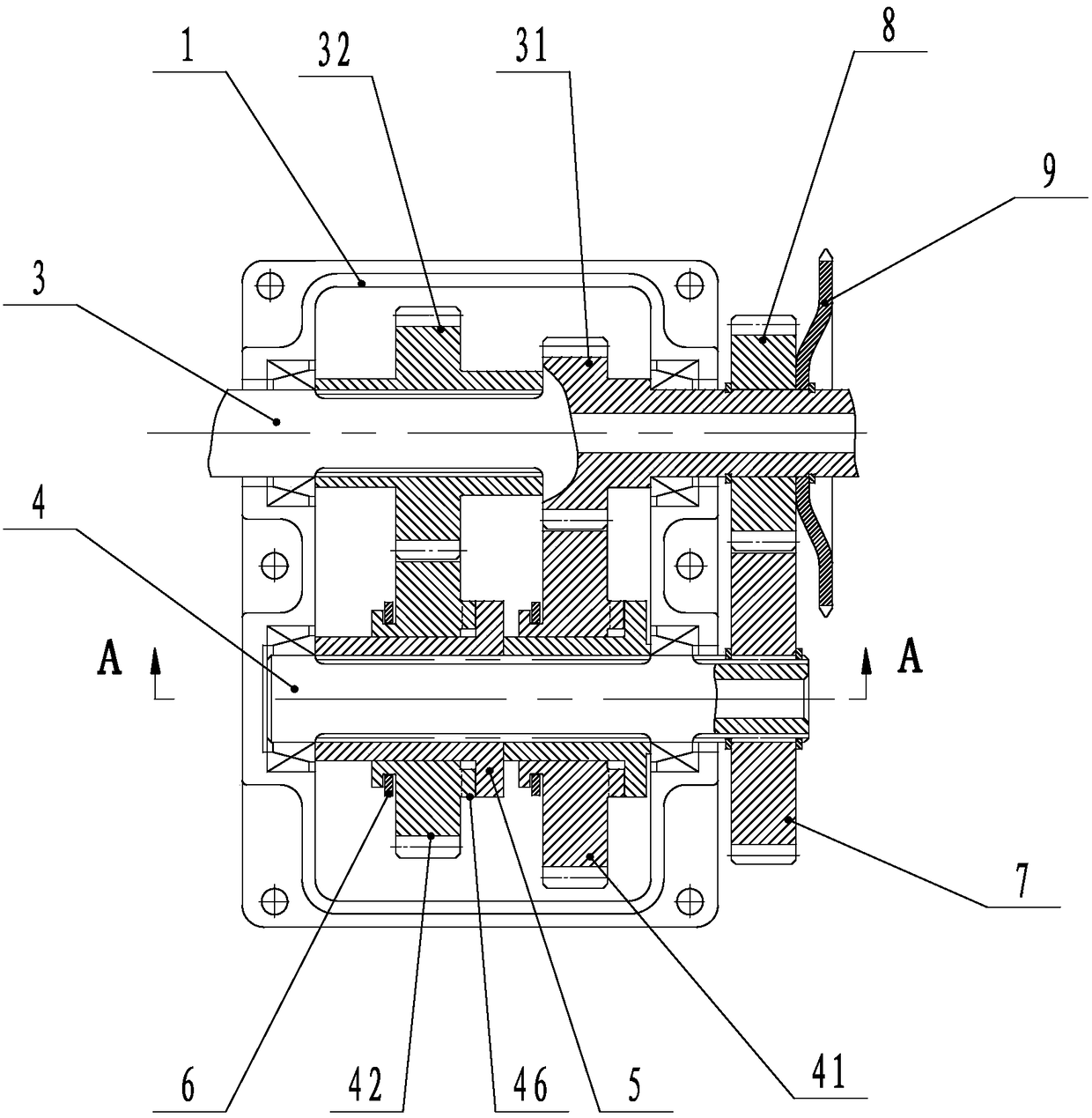

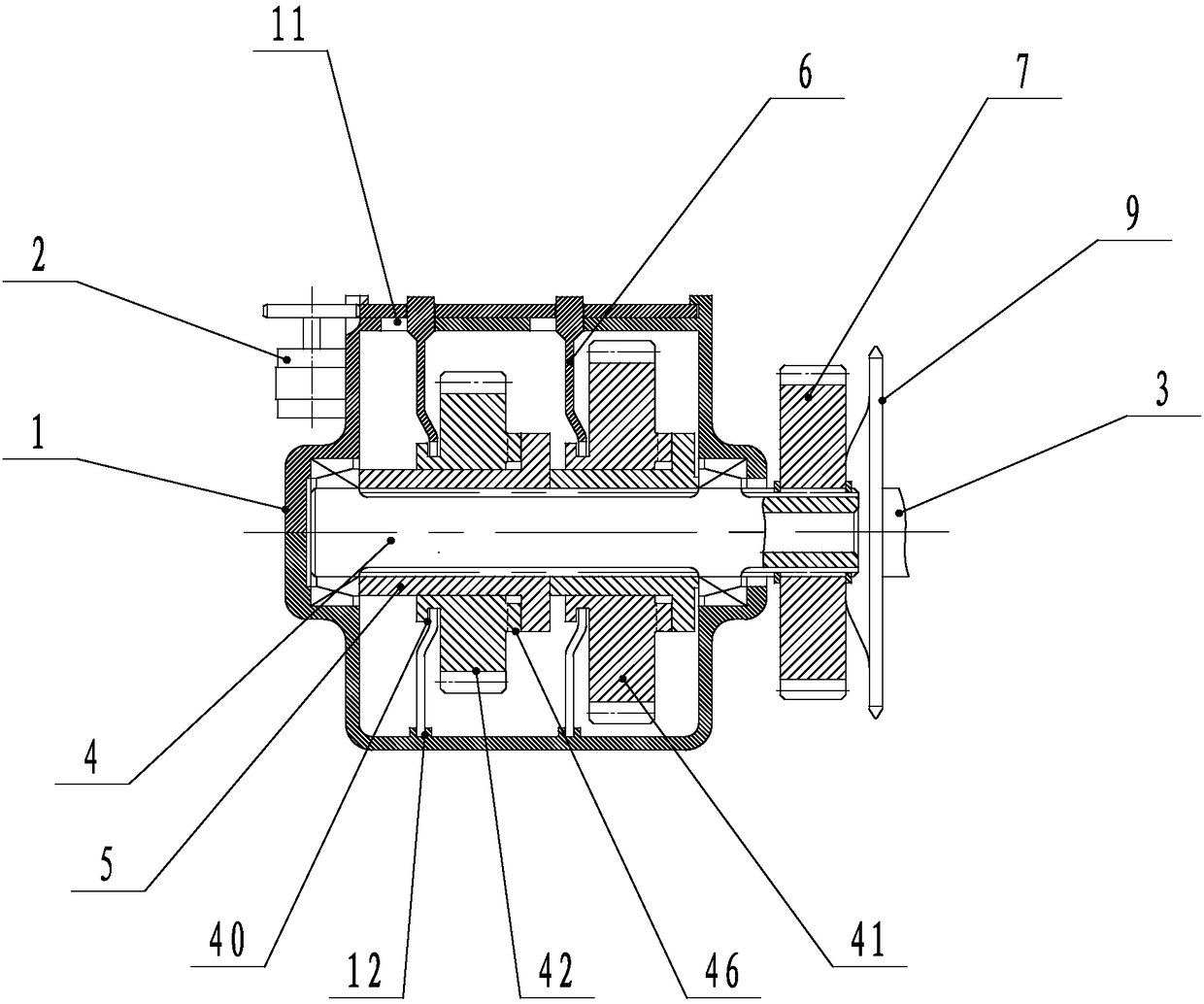

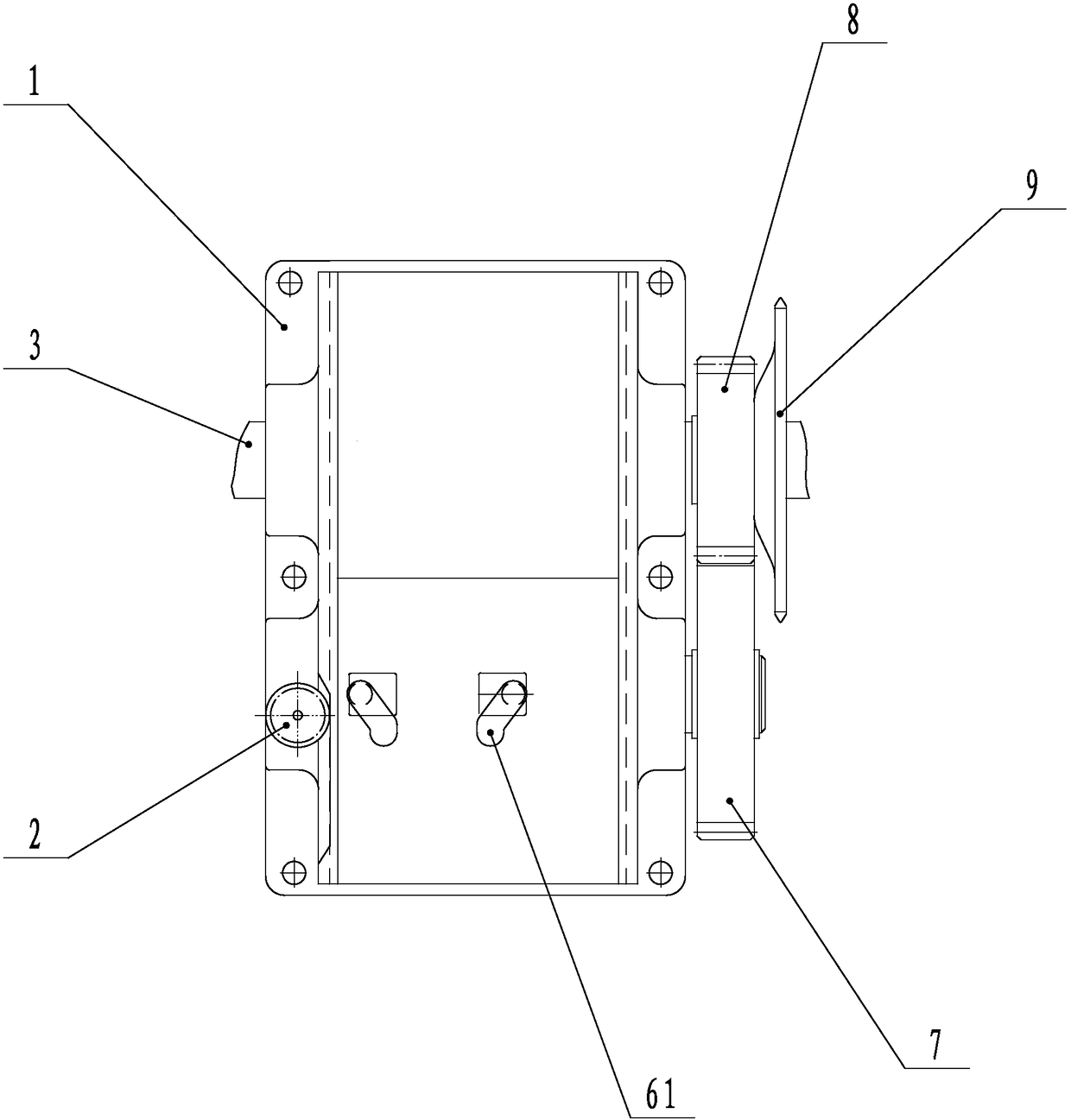

[0028] Example 1: Reference Figure 1 to Figure 3 , A specific embodiment of the present invention, the transmission device is provided with two gears, the middle shaft 3 is provided with two gears of driving gears, of which the first gear driving gear 31 is integrally formed on the middle shaft 3, and the second gear driving gear 32 is located on the left side of the first-speed driving gear 31 and is fixedly connected to the central shaft 3. The driven shaft 4 is fixedly connected to two clutch sleeves 5 from right to left, and the two clutch sleeves 5 are respectively movably engaged The first-speed driven gear 41 and the second-speed driven gear 42 are connected.

Embodiment 2

[0029] Example 2: Reference Figure 4 to Figure 6 , A specific embodiment of the present invention, the transmission device is provided with three gears, the middle shaft 3 is provided with three gears of driving gears, wherein the first gear driving gear 31 is integrally formed on the middle shaft 3, and the second gear driving gear 32 is located The first-speed driving gear 31 is fixedly connected to the left side of the middle shaft 3, and the third-speed driving gear 33 is movably connected with the clutch sleeve 5 fixedly connected to the middle shaft 3, and the driven shaft 4 is fixedly connected with two On the clutch sleeve 5, the two clutch sleeves 5 are movably connected to a first-speed driven gear 41 and a second-speed driven gear 42 respectively, and the third-speed driven gear 43 is fixedly connected to the driven shaft 4.

Embodiment 3

[0030] Example 3: Reference Figure 7 to Figure 9 , In another specific embodiment of the present invention, the speed change device is provided with four gears, the middle shaft 3 is provided with four gears of driving gears, and the first gear driving gear 31 is integrally formed on the middle shaft 3, and the second gear is driven The gear 32 is located on the left side of the first-speed driving gear 31 and is fixedly connected to the middle shaft 3. The third-speed and fourth-speed driving gears 33, 34 are movably connected to the corresponding clutch sleeve 5 fixedly connected to the middle shaft 3. Two clutch sleeves 5 are fixedly connected to the moving shaft 4, and the two clutch sleeves 5 are respectively movably connected with a first-speed driven gear 41 and a second-speed driven gear 42, and third-speed and fourth-speed driven gears 43, 44 respectively. They are fixedly connected to the driven shaft 4 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com