Roll material transport device with material feeding prompt function and use method thereof

A technology of prompting function and conveying device, which is applied in the directions of transportation and packaging, coiling strips, and thin material processing, etc., and can solve the problems of high difficulty in assembly line management and monitoring, enlarged inner diameter, and lack of filling prompting function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

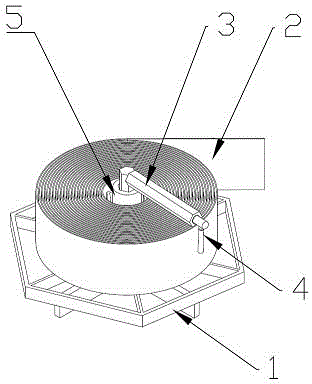

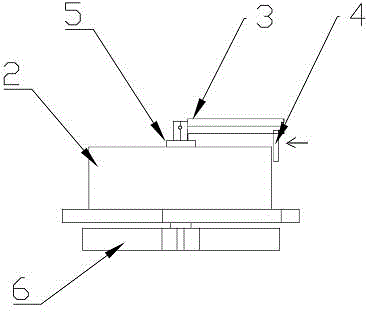

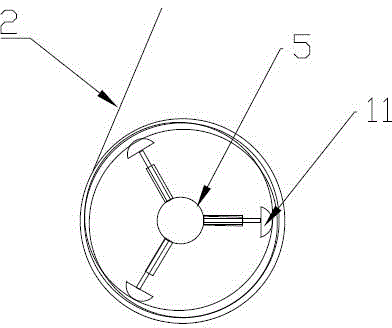

[0018] Example : see Figures 1 to 4 , the purpose of the present invention is to solve the above problems, to provide a stable use, simple operation, high production efficiency with a coil material feeding device with prompt function.

[0019] Technical scheme of the present invention is:

[0020] A coil conveying device with a prompt function for adding materials, including a turntable, a turntable base and a rotating shaft, the turntable is set above the turntable base, a rotating shaft with bearings is arranged between the turntable and the turntable base, and a hole is opened on the top of the rotating shaft to prevent the coil from Knot off the ring, install the limit gear arm in the hole, the limit gear arm has two sections, the middle is the gear arm connector, the limit gear arm longitudinal rod is inserted into the opening of the rotating shaft, and the limit gear arm cross bar is equipped with The tension spring pre-tightens the coil material through the "L"-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com