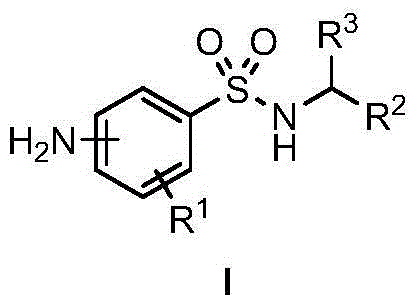

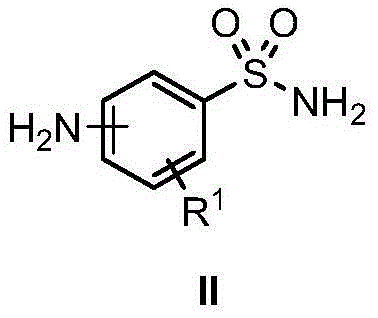

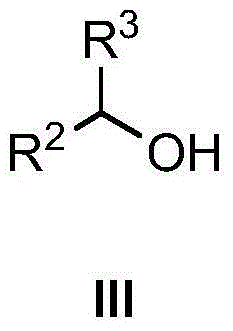

Amino-(N-alkyl) benzsulfamide synthesis method

A technology for aminobenzenesulfonamide and amino synthesis, which is applied in the preparation of sulfonic acid amides, chemical instruments and methods, organic chemistry, etc., can solve problems such as low atom economy, and achieve broad development prospects and high economy effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: 4-amino-N-benzylbenzenesulfonamide

[0022] 4-amino-N-benzylbenzenesulfonamide

[0023]

[0024] Under nitrogen protection, 4-aminobenzenesulfonamide (172mg, 1mmol), [Cp*IrCl 2 ] 2 (8mg, 0.01mmol, 1mol%), cesium carbonate (65mg, 0.2mmol), benzyl alcohol (130mg, 1.2mmol), and tert-amyl alcohol (1mL) were sequentially added to a 25mL Schlenk reaction flask. After the mixture was reacted at 120°C for 12 hours, it was cooled to room temperature, and the solvent was removed under reduced pressure in vacuo. Then the pure target compound was obtained by column chromatography (developing solvent: ethyl acetate / n-hexane), yield: 88%.

[0025] 1 H NMR (500MHz, DMSO-d 6 )δ7.62(br s,1H,NH),7.44(d,J=8.6Hz,2H,ArH),7.31-7.20(m,5H,ArH),6.60(d,J=8.6Hz,2H,ArH ),5.92(s,2H,NH 2 ),3.87(s,2H,NCH 2 ); 13 C NMR (125MHz, DMSO-d 6 )δ152.4, 138.0, 128.4, 127.5, 127.0, 125.6, 112.6, 46.0.

Embodiment 2

[0026] Embodiment 2: N-(4-methylbenzyl)-4-aminobenzenesulfonamide

[0027] N-(4-methylbenzyl)-4-aminobenzenesulfonamide

[0028]

[0029] Under nitrogen protection, 4-aminobenzenesulfonamide (172mg, 1mmol), [Cp*IrCl 2 ] 2 (8mg, 0.01mmol, 1mol%), cesium carbonate (65mg, 0.2mmol), p-methylbenzyl alcohol (147mg, 1.2mmol), and tert-amyl alcohol (1.0mL) were sequentially added to a 25mL Schlenk reaction flask. After the mixture was reacted at 120°C for 12 hours, it was cooled to room temperature, and the solvent was removed under reduced pressure in vacuo. Then the pure target compound was obtained by column chromatography (developing solvent: ethyl acetate / n-hexane), yield: 86%.

[0030] 1 H NMR (500MHz, DMSO-d 6 )δ7.55(br s,1H,NH),7.43(d,J=8.6Hz,2H,ArH),7.10(q,J=7.4Hz,4H,ArH),6.60(d,J=8.6Hz, 2H,ArH),5.91(s,2H,NH 2 ),3.81(s,2H,NCH 2 ),2.26(s,3H,CH 3 ); 13 C NMR (125MHz, DMSO-d 6 )δ152.4,136.0,135.0,128.7,128.4,127.5,125.6,112.6,45.8,20.6; HRMS-EI(70eV)m / z calcd for C...

Embodiment 3

[0031] Embodiment 3: N-(4-isopropylbenzyl)-4-aminobenzenesulfonamide

[0032] N-(4-isopropylbenzyl)-4-aminobenzenesulfonamide

[0033]

[0034] Under nitrogen protection, 4-aminobenzenesulfonamide (172mg, 1mmol), [Cp*IrCl 2 ] 2 (8mg, 0.01mmol, 1mol%), cesium carbonate (65mg, 0.2mmol), p-cymenyl alcohol (180mg, 1.2mmol), and tert-amyl alcohol (1.0mL) were sequentially added to a 25mL Schlenk reaction flask. After the mixture was reacted at 120°C for 12 hours, it was cooled to room temperature, and the solvent was removed under reduced pressure in vacuo. Then the pure target compound was obtained by column chromatography (developing solvent: ethyl acetate / n-hexane), yield: 80%.

[0035] 1 H NMR (500MHz, DMSO-d 6 )δ7.55(br s,1H,NH),7.43(d,J=8.5Hz,2H,ArH),7.14(s,4H,ArH),6.60(d,J=8.5Hz,2H,ArH), 5.91(s,2H,NH 2 ),3.82(s,2H,NCH 2 ), 2.90-2.79 (heptet, J=6.9Hz, 1H, CH), 1.17 (d, J=7.0Hz, 6H, 2xCH 3 ); 13 C NMR (125MHz, DMSO-d 6)δ152.4,147.2,135.3,128.4,127.6,126.0,125.6,1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com